Tank wallboard molding male die

A wallboard forming and punching technology, which is applied in the field of stamping die parts, can solve the problems of low machining accuracy, high technical requirements, and high production costs, and achieve the effects of improving production efficiency, high dimensional accuracy, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

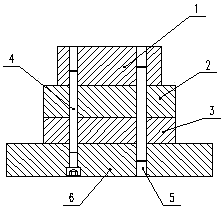

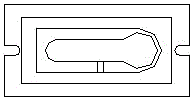

[0016] As shown in the accompanying drawings: a box wall panel forming punch, which includes a punch 1, a punch fixing plate 2, a backing plate 3, a socket head cap screw 4, a cylindrical pin 5, and a lower mold fixing plate 6.

[0017] The punch 1 is made of Cr12 material, a bolt mounting hole and a positioning hole are arranged in the middle of the punch, an arc boss is arranged on the side of the punch, and a small hole is arranged on the left side of the punch. Arc, the right side of the left punch is provided with a large arc.

[0018] Described punch fixed plate 2 is made of 45# material, is provided with punch mounting hole in the center of punch fixed plate, is provided with bolt mounting hole around the punch fixed plate, on punch fixed plate There is a rounded corner on the upper left corner of the punch, and a transition arc is set on the right side of the punch fixed plate.

[0019] The backing plate 3 is made of a 30mm steel plate, and bolt mounting holes are arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com