Cooperative potato seeder

A seeding device and potato technology, applied in the field of agricultural machinery, can solve the problems of low unit yield and the like, and achieve the effects of improving the success rate, good integration and connection, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

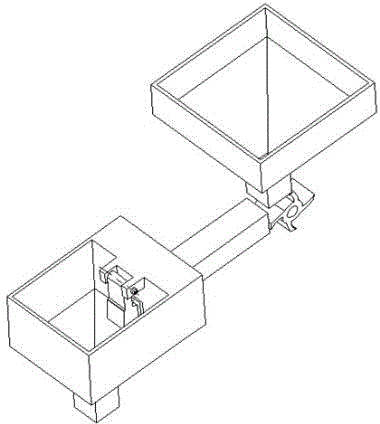

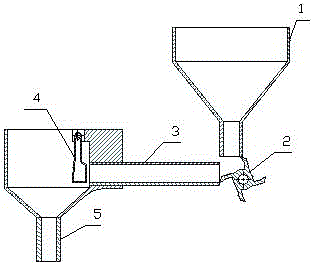

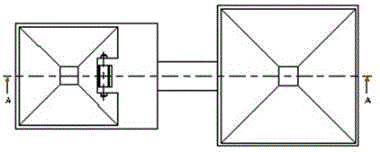

[0014] The structural composition and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. The invention includes a hopper, a feeding ratchet, a feeding pipe, a lever and a discharging pipe, and is characterized in that: the hopper and the feeding pipe are connected to the feeding ratchet, and the feeding pipe and the discharging pipe are connected to the feeding Ratchet connection.

[0015] Seed potatoes fall from the hopper 1 into the groove of the feeding ratchet 2 due to gravity, and the feeding pushing action is realized through the rotation of the feeding ratchet 2 . The seed potatoes enter the feeding pipe 3 side by side and under the thrust of the feeding ratchet 2, the seed potatoes push away the spoon-shaped lever 4 to make the seed potatoes fall. Due to the action of gravity, the lever 4 returns immediately after the seed potatoes are separated to realize sowing o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com