A carbon source dosing feed-forward-feedback control device and control method

A feedback control, carbon source technology, applied in the direction of using electric device flow control, etc., can solve problems such as the inability to meet the requirements of stable control and water effluent standards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

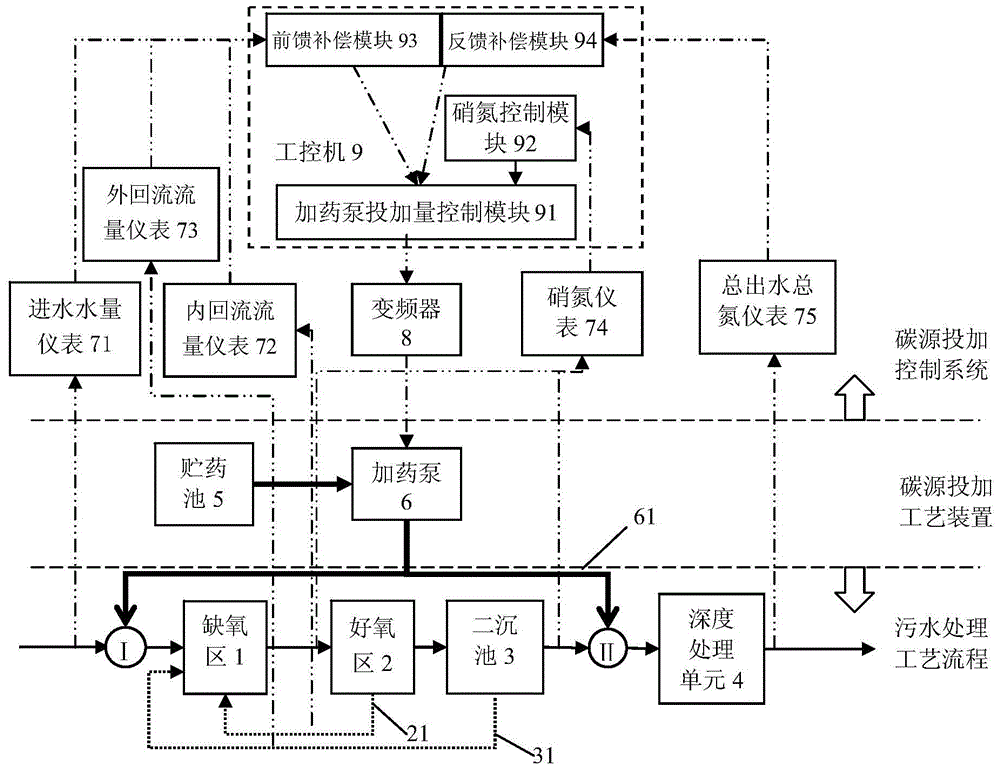

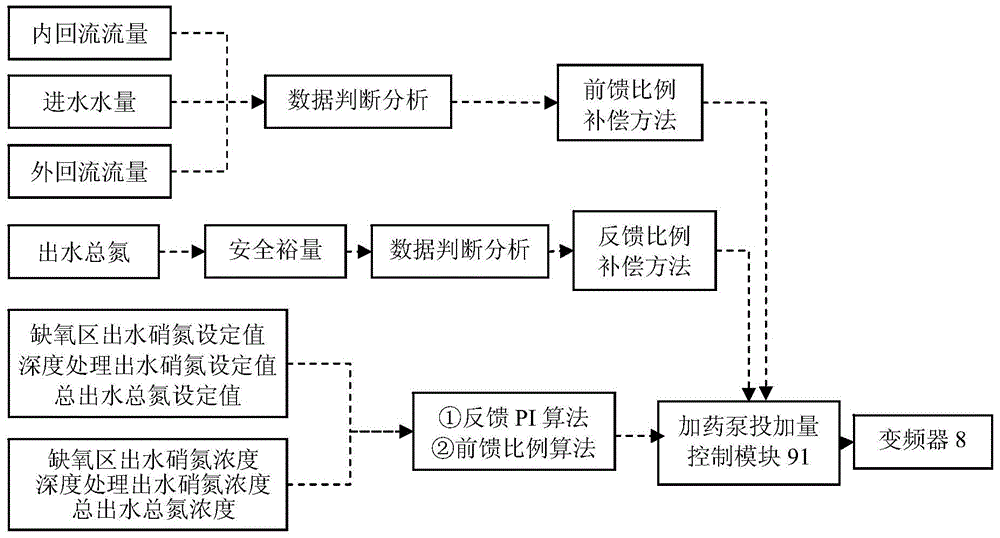

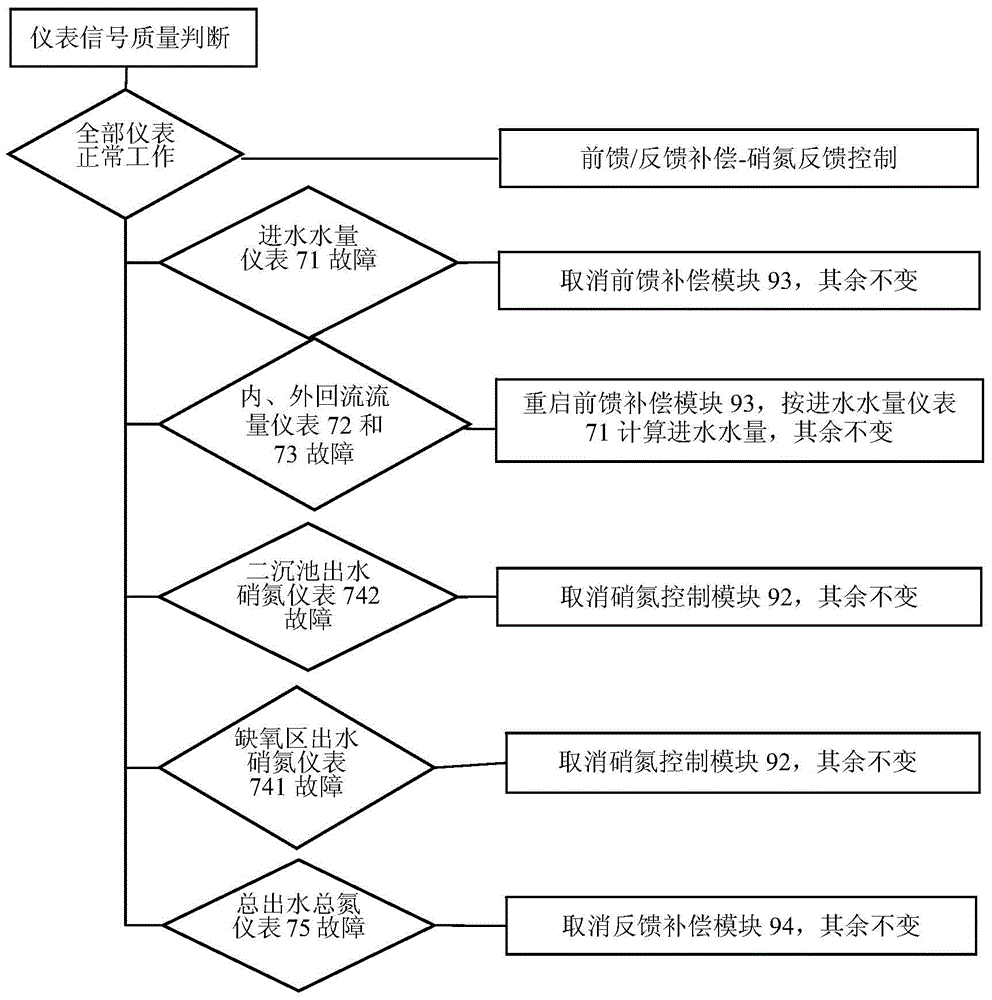

Embodiment 1

[0134] Process operation status: A city sewage treatment plant adopts AAO process, with a scale of 100,000 tons / day, divided into two series, adopting biochemical denitrification process, setting up three carbon source dosing pumps 6, and the dosing point I is set in the anoxic area 1 entrance ( figure 1 Shown), the total nitrogen standard of the effluent is 15mg / L. An electromagnetic flowmeter is set in front of the water inlet of the anoxic zone 1 as the water inlet meter 71, an online nitrate meter is set at the outlet of the anoxic zone 1 as the nitrate meter 741 of the anoxic zone, and an online nitrate meter is set at the outlet of the secondary sedimentation tank 3 The nitrate nitrogen meter is used as the nitrate nitrogen meter 742 in the secondary sedimentation tank, and the total effluent total nitrogen meter 75 is set at the water outlet of the advanced treatment unit 4 . A carbon source dosing control cabinet is added near the dosing pump 6, and an industrial comp...

Embodiment 2

[0147]Process operation status: The Orbal oxidation ditch process of a certain urban sewage treatment plant, with a scale of 50,000 tons / day, adopts a biochemical denitrification process, and two carbon source dosing pumps 6 are installed. The discharge standard of total nitrogen in the effluent is 15mg / L. An electromagnetic flowmeter is set before the water inlet of the oxidation ditch as the water inflow meter 71, an online nitrate-nitrogen meter is set at the outlet of the outer ditch as the nitrate-nitrogen meter 741 in the anoxic zone, and an online nitrate-nitrogen meter is set at the outlet of the secondary sedimentation tank 3 as the secondary A nitrate nitrogen meter 742 in the settling tank, and a total effluent total nitrogen meter 75 are set at the water outlet of the advanced treatment unit 4 . The PLC collects instrument signals such as the nitrate-nitrogen meter 741 in the anoxic area, the nitrate-nitrogen meter 742 in the secondary sedimentation tank, the total...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com