Vinyl acetate wood adhesive and preparation method thereof

A vinyl acetate and wood adhesive technology, applied in the field of polymer chemistry, can solve the problems of poor water resistance, cold resistance and moisture resistance, decreased adhesive strength of adhesive films, poor mechanical stability, etc., and achieves good water resistance, The effect of stable reaction and improved emulsion stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

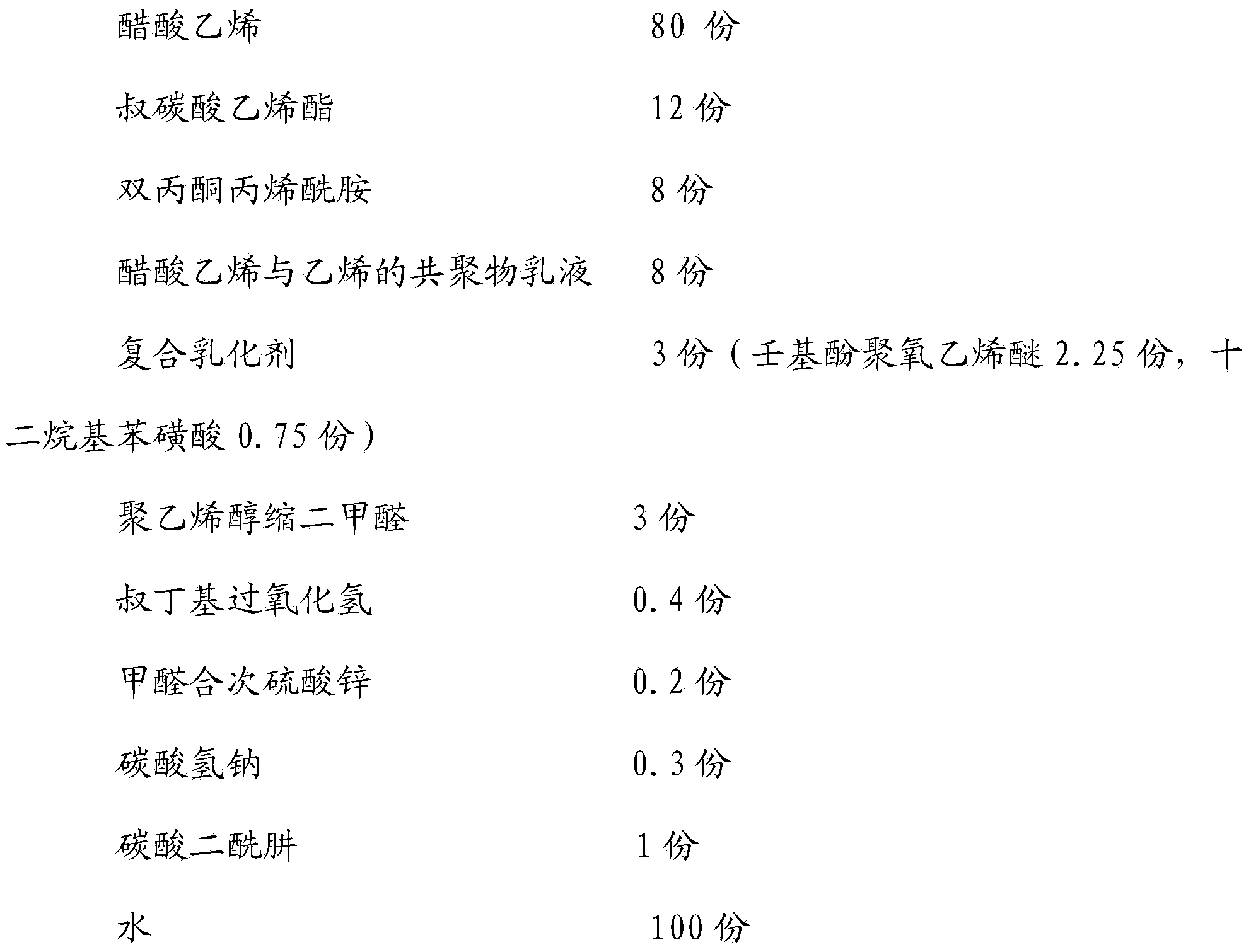

[0034] The vinyl acetate wood adhesive of the present invention is made of the following components in parts by weight:

[0035]

[0036] The preparation process is as follows:

[0037] (1) Prepare the emulsifier solution: add 30 parts of deionized water and 3 parts of the compound emulsifier into the emulsifier tank, start the stirrer, heat up to 60°C, stir for 30 minutes, and fully mix and dissolve;

[0038] (2) Prepare initiator solution: add 10 parts of deionized water and 0.4 parts of tert-butyl hydroperoxide to initiator tank a, stir to dissolve, and add 10 parts of deionized water and 0.2 parts of zinc formaldehyde sulfoxylate to initiator tank b. Stir to dissolve;

[0039] (3) Mix 80 parts of vinyl acetate and 12 parts of ethylene tertiary carbonate to obtain a mixed monomer;

[0040] (4) Add 40 parts of deionized water to the reactor, start the agitator, add 8 parts of vinyl acetate and ethylene copolymer emulsion, 3 parts of protective colloid, 0.3 parts of sodium bicarbonate...

Embodiment 2

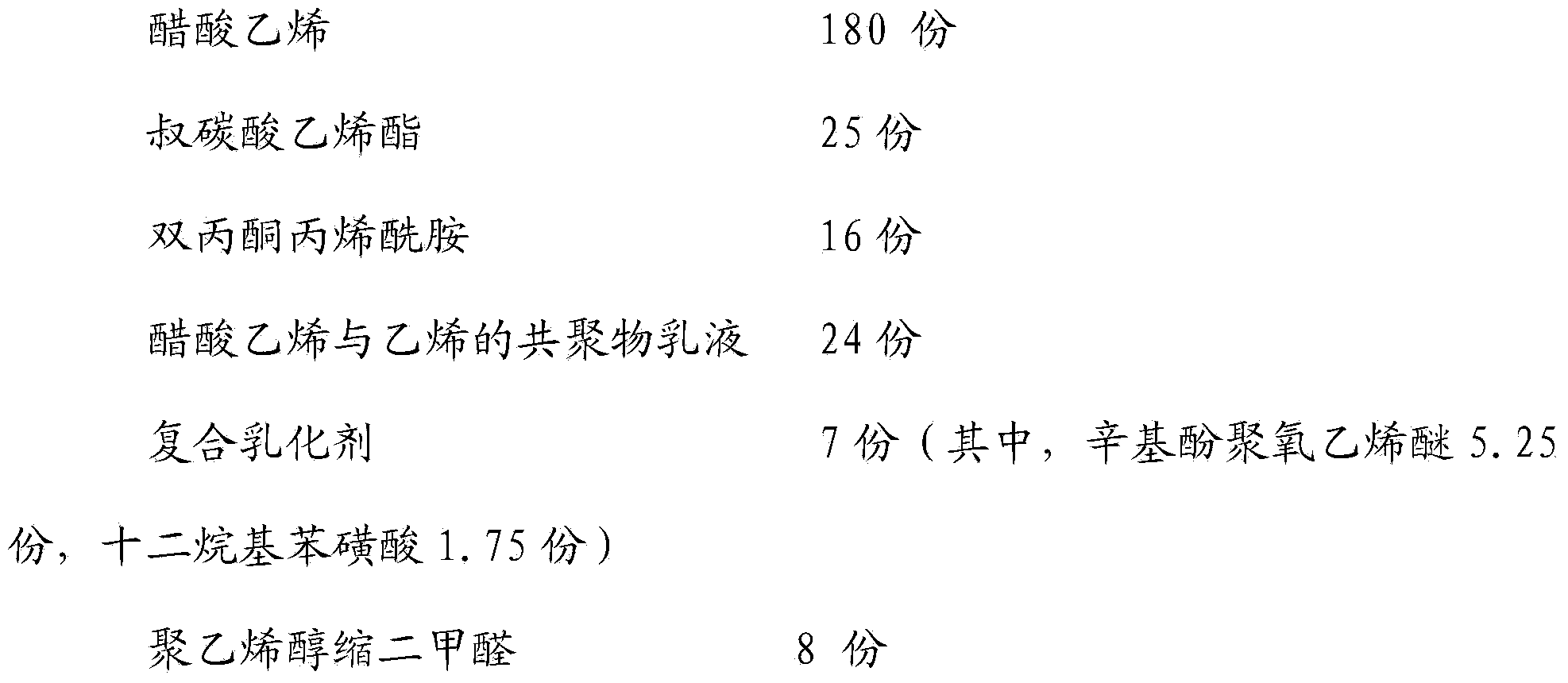

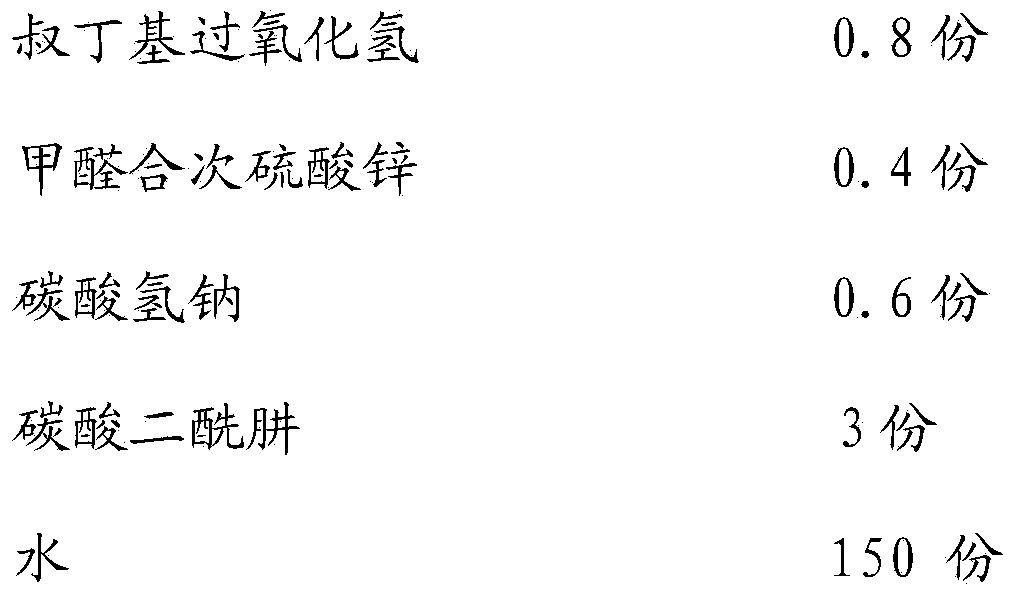

[0044] The vinyl acetate wood adhesive of the present invention is made of the following components in parts by weight:

[0045]

[0046]

[0047] The preparation process is as follows:

[0048] (1) Prepare the emulsifier solution: add 40 parts of deionized water and 7 parts of the compound emulsifier into the emulsifier tank, start the stirrer, heat up to 60°C, stir for 30 minutes, and fully mix and dissolve;

[0049] (2) Prepare initiator solution: add 15 parts of deionized water and 0.8 parts of tert-butyl hydroperoxide to initiator tank a, stir to dissolve, and add 15 parts of deionized water and 0.4 parts of zinc formaldehyde sulfoxylate to initiator tank b. Stir to dissolve;

[0050] (3) Mix 180 parts of vinyl acetate and 25 parts of ethylene tertiary carbonate to obtain a mixed monomer;

[0051] (4) Add 70 parts of deionized water to the reactor, start the agitator, add 24 parts of vinyl acetate and ethylene copolymer emulsion, 8 parts of protective colloid, 0.6 parts of sodium ...

Embodiment 3

[0054] Example 3 Performance Test

[0055] The following performance index tests were performed on the wood adhesives prepared in Examples 1 and 2:

[0056] (1) Appearance: Direct observation method

[0057] (2) Viscosity: tested according to national standard GB2794-81

[0058] Detection conditions: room temperature (25±1℃), 2# rotor, rotating speed 60r / min.

[0059] Testing method: Put the sample to be tested into the testing container, immerse the selected rotor in the container, and ensure that the liquid surface of the sample covers the rotor. Turn on the instrument, keep it at 25±1℃ for 10 minutes, and record the result after the indicator reaches a basic stability. Repeat the measurement three times and then take the average.

[0060] (3) Bonding strength: testing according to standard HG / T2727-2010.

[0061] Detection method: spread the evenly stirred adhesive on the two bonding surfaces of the test piece, the bonding area is 15mm×15mm, and the amount of glue is about 100g / m 2 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com