A stamping machine system

A stamp machine and seal technology, applied in the field of stamp machine systems, can solve the problems of easy replacement of stamped objects and low working efficiency of closed stamp machines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

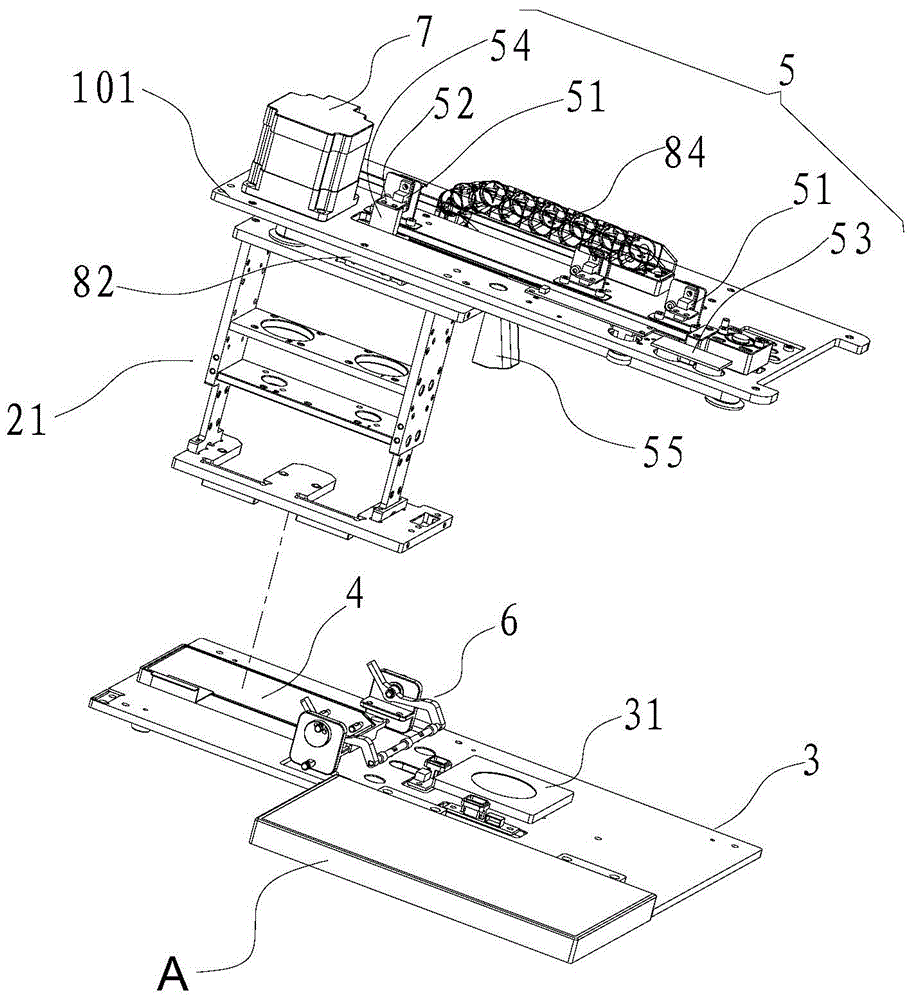

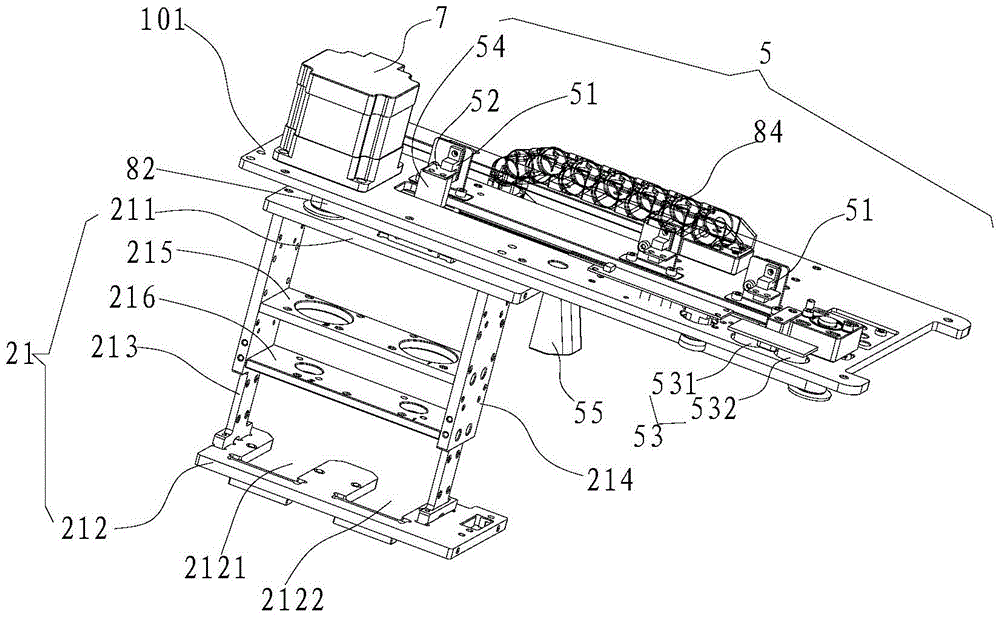

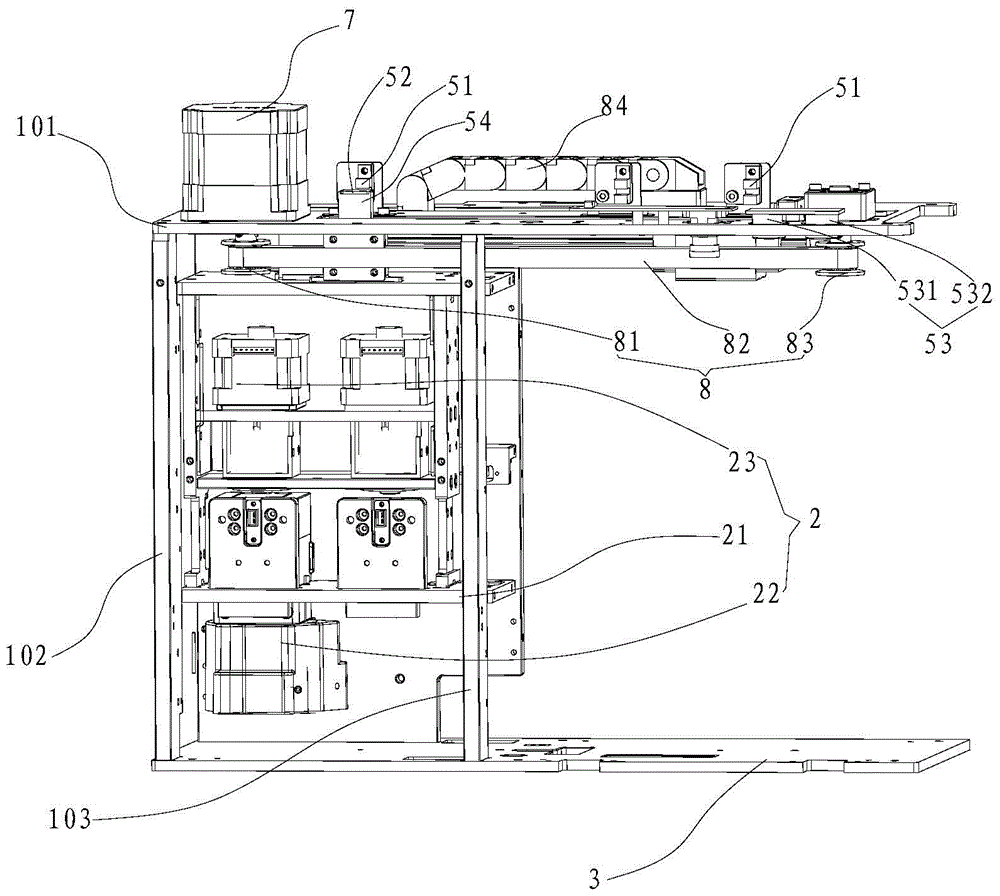

[0043] Such as figure 1 , 2 , 3, the present invention discloses a stamp machine system, including a stamp machine server, a CPU processor, a stamp mechanism 2, a support mechanism, a stamp platform 3, an ink tank 4, a detection assembly 5, a paper pressing mechanism 6, Power components and guide components, including:

[0044] The stamp machine server receives and saves the information transmitted by the CPU processor, and sends control instructions through the CPU processor, and communicates with the CPU processor through the USB interface;

[0045] The CPU processor is connected with the power component, the stamping mechanism, the detection component and the stamp machine server, and controls the stamp in the stamping mechanism 2 to automatically dip the stamp in the ink tank 4 according to the control command input by the user through the user interaction interface 11, And control the power assembly to move the stamping mechanism 2 to the designated position;

[0046] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com