Automatic tow hook welding equipment

An automatic welding and equipment technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems such as unstable quality, high labor intensity, large deformation, etc., to reduce the number of clamping times and improve production efficiency , running smoothly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

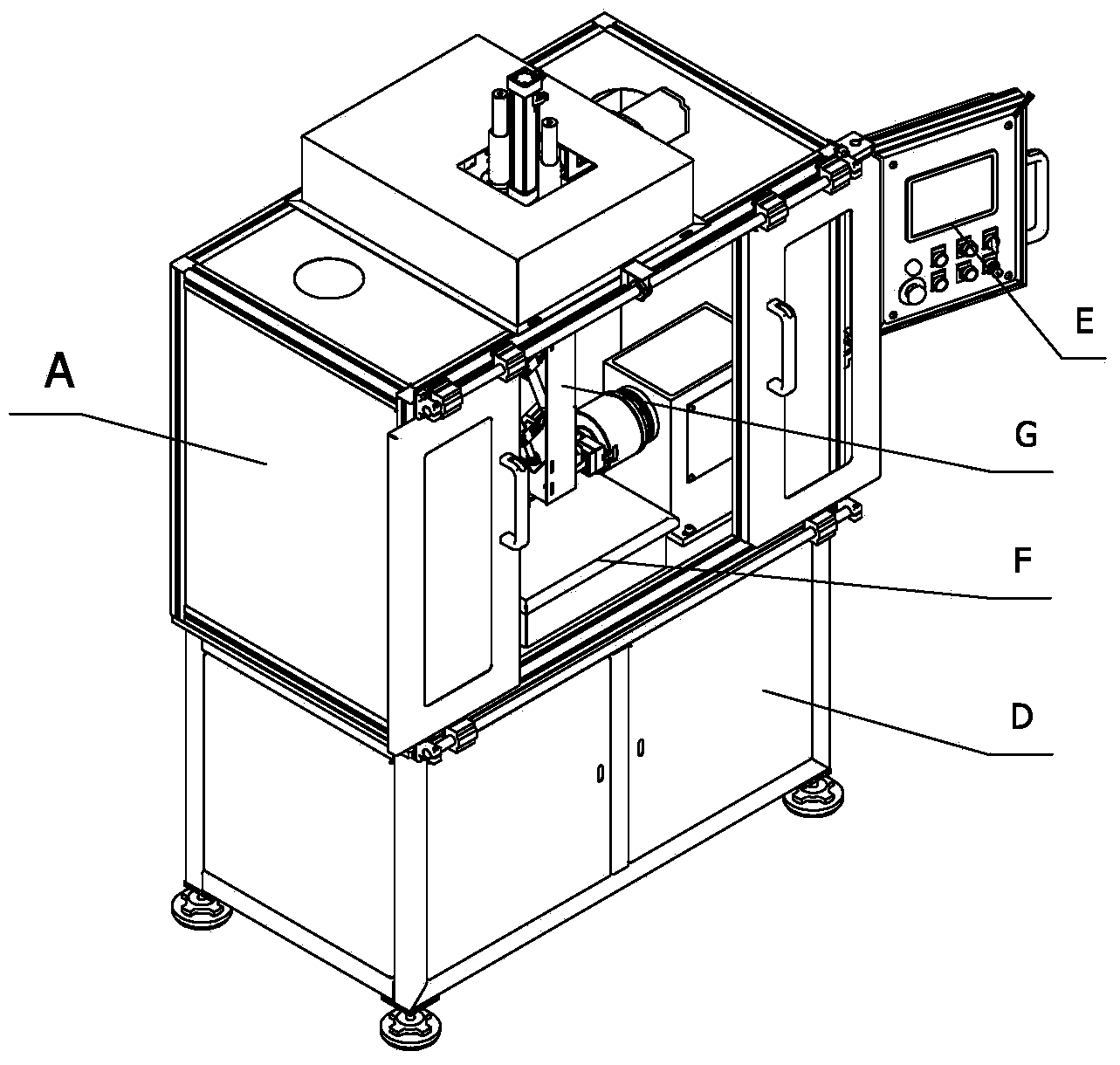

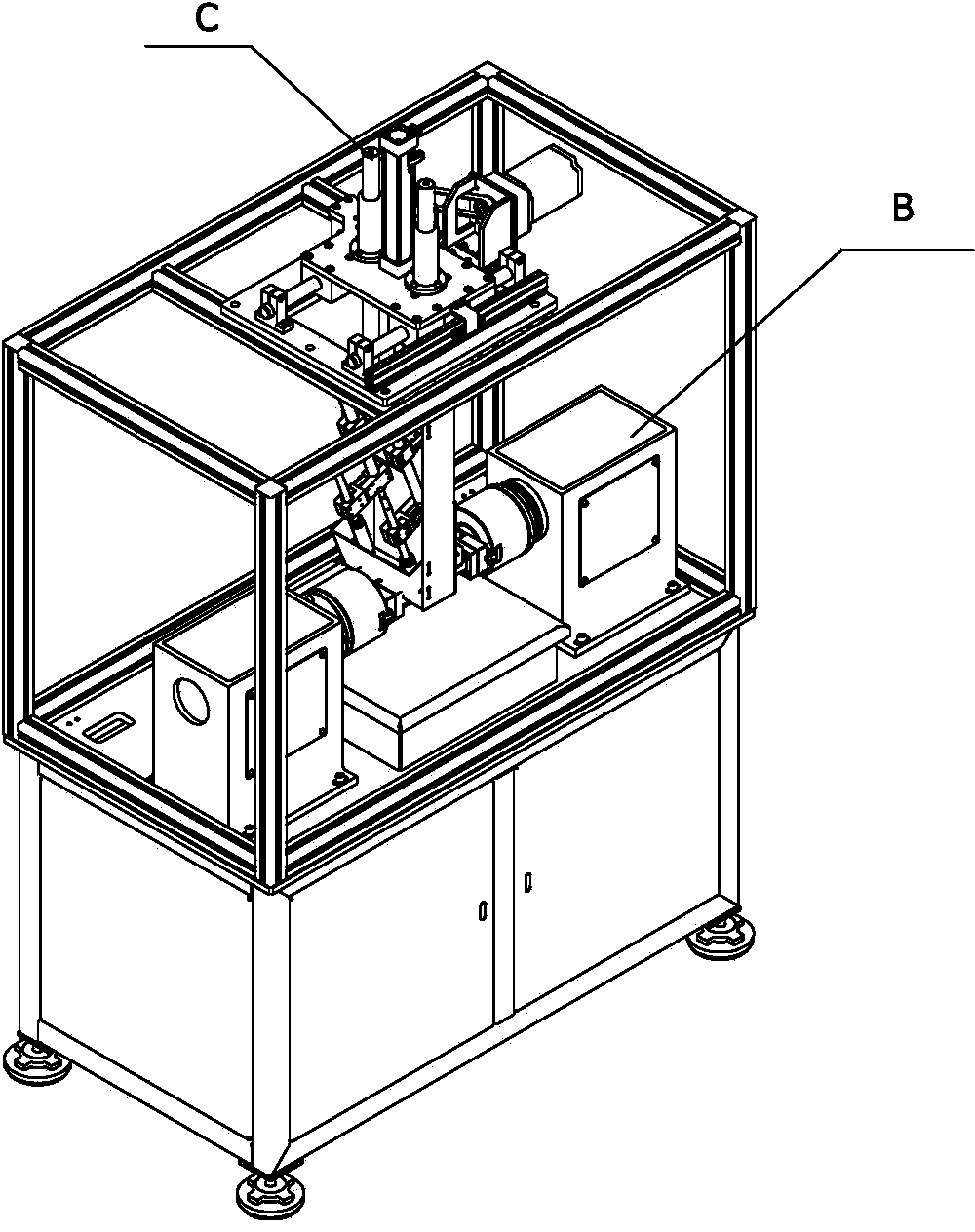

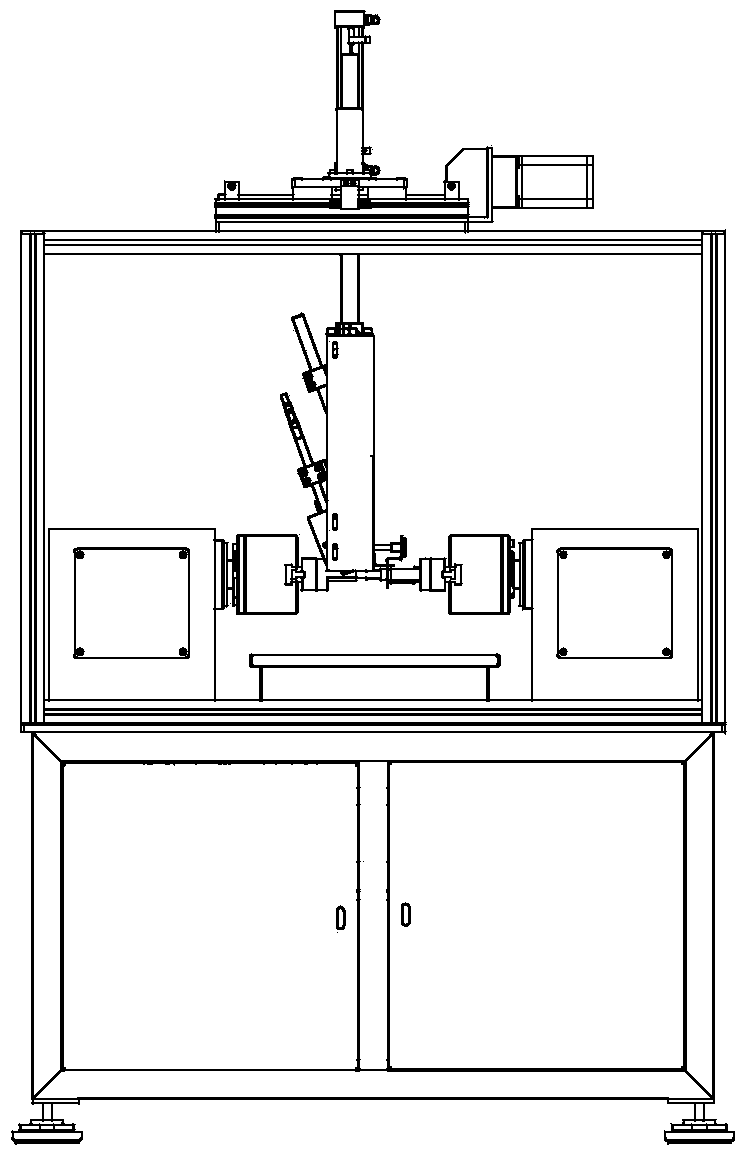

[0027] combine figure 1 —— Figure 4 As shown, a tow hook automatic welding equipment is mainly composed of three parts: a chassis cover A, a flipping fixture assembly B and a welding head assembly C. In addition, it also includes an electrical cabinet D, a touch screen E, a material receiving box F and a welding Slag baffle G. The overturning jig assembly B and the welding head assembly C are arranged in the chassis cover A, and the welding head assembly C is arranged right above the overturning jig assembly B in the left and right center. The electrical cabinet D is located directly below the case cover A, the touch screen E is located outside the case cover A, and the material receiving box F is arranged at the bottom of the case cover A. One side of the case cover A is open, which is convenient for the operator to operate, and the welding slag baffle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com