Drive system of AC motor and elevator equipment using the drive system

An AC motor and drive system technology, which is applied to AC motor control, elevators in buildings, control systems, etc., can solve the problems of increasing the number of components, rising costs, and inability to obtain circulating current suppression control, and achieves suppression of circulating current, The effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

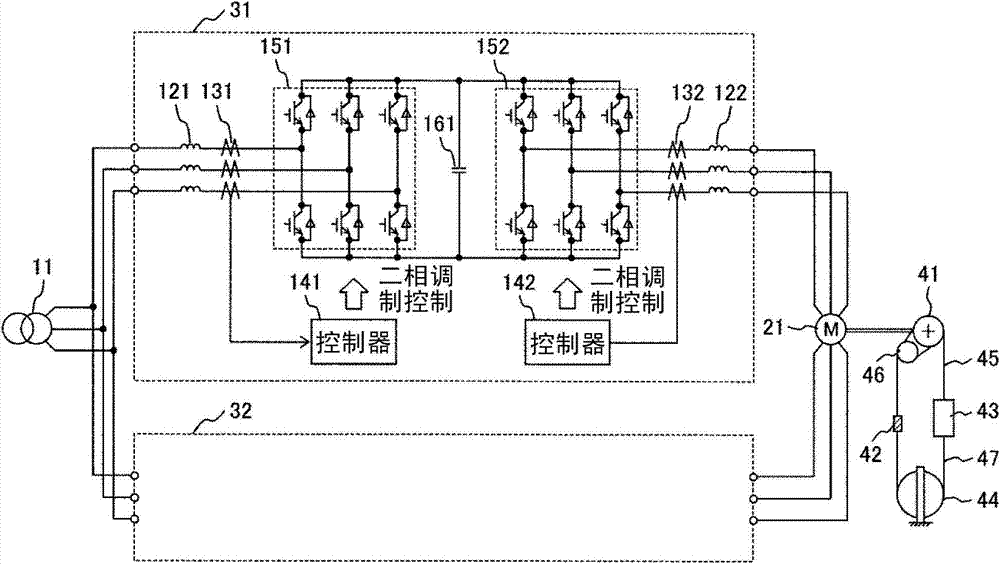

[0039] figure 1 A drive system for an AC motor as a first embodiment of the present invention is shown. This drive system is used to drive the elevator.

[0040] In this embodiment, the power conversion device 31 and the power conversion device 32 connected in parallel convert the three-phase alternating current with constant voltage and constant frequency input from the commercial power supply 11 into three-phase alternating current with variable voltage and variable frequency output. The three-phase AC motor 21 is driven by the outputted three-phase AC power. The three-phase AC motor 21 has double windings, thereby suppressing circulating current flowing between the power converters as will be described later. In addition, as the three-phase AC motor 21, an induction motor, a permanent magnet synchronous motor, or the like is used.

[0041] In the elevator of this embodiment, the sling 45 is wound around the sheave 41 and the pulley 46, and a counterweight 42 and an ele...

no. 2 example

[0057] Figure 5 A drive system for an AC motor as a second embodiment of the present invention is shown. Figure 5 It is a block diagram showing the converter sections 151a, 151b (CONV) and the inverter sections 152a, 152b (INV), and the specific main circuit configuration is omitted in the figure. In addition, the description of the elevator part is omitted. In addition, since the controller and the power source side current detector of the power conversion device 32 are the same as those of the power conversion device 31 , descriptions of these components are omitted here.

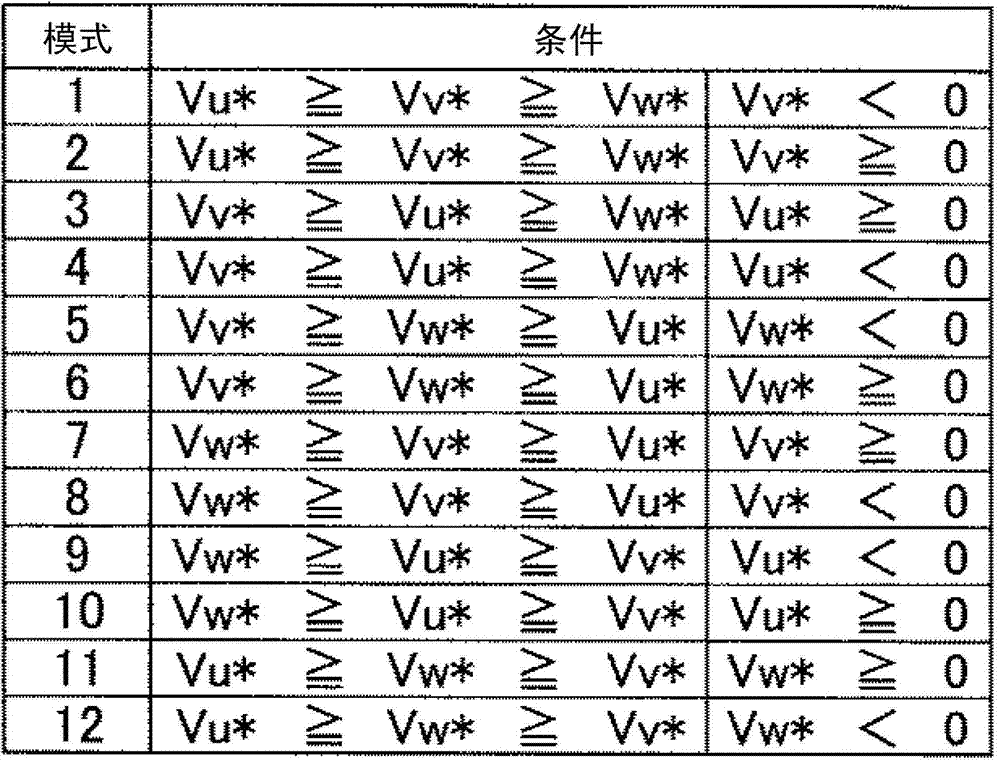

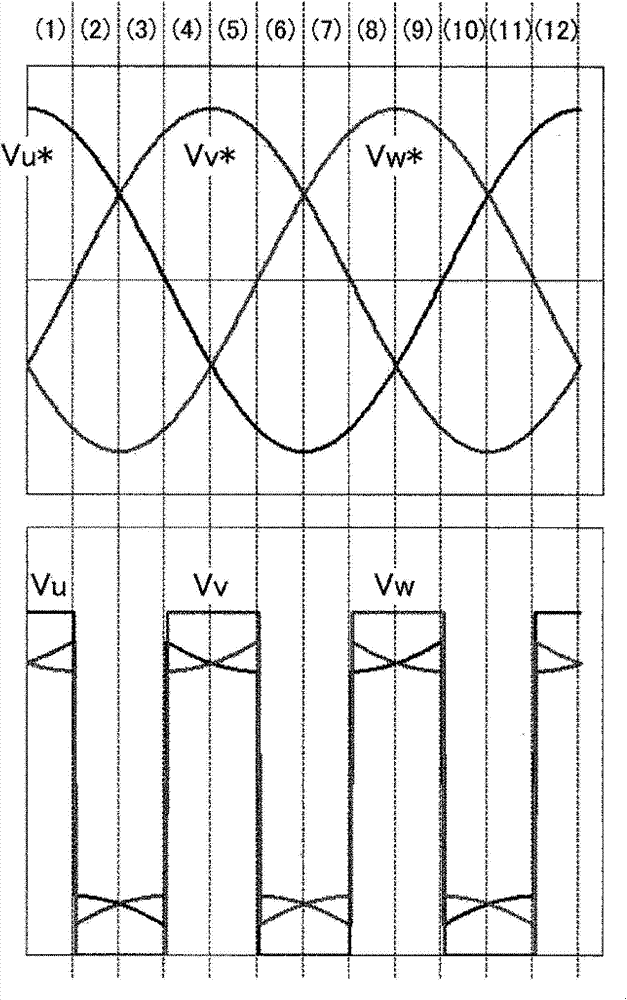

[0058] and figure 1 The same as the first embodiment of the above, the inverter part 152a in the power conversion device 31 is PWM controlled by the controller 142a in a two-phase modulation manner, and the inverter part 152b in the power conversion device 32 is also controlled by a not shown The controller performs PWM control with two-phase modulation. In addition, the AC output of the inverter s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com