A solar cell module with multiple sub-batteries connected in series and its preparation method

A technology of solar cells and sub-batteries, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of limited number of sub-batteries, limited voltage that can be connected in series with sub-batteries, hot spot effect can not be effectively controlled, etc., and achieve simple process Anti-hot spot effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

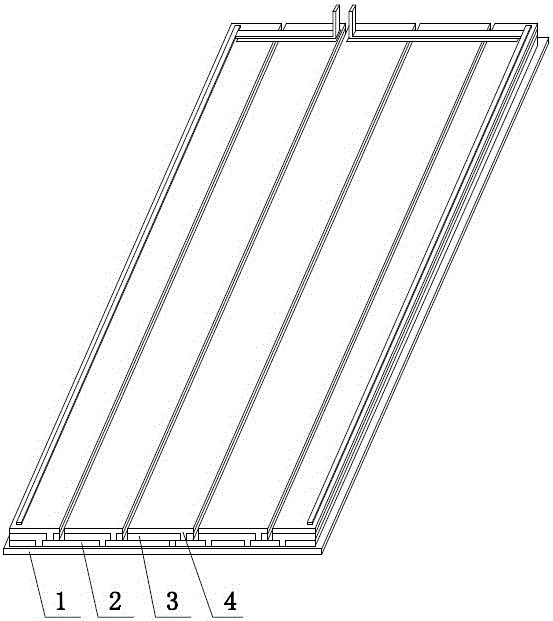

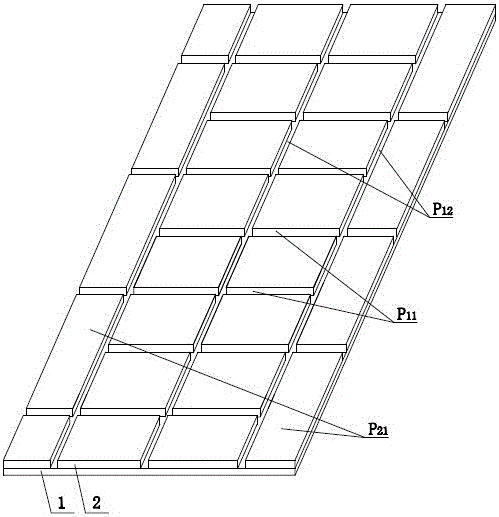

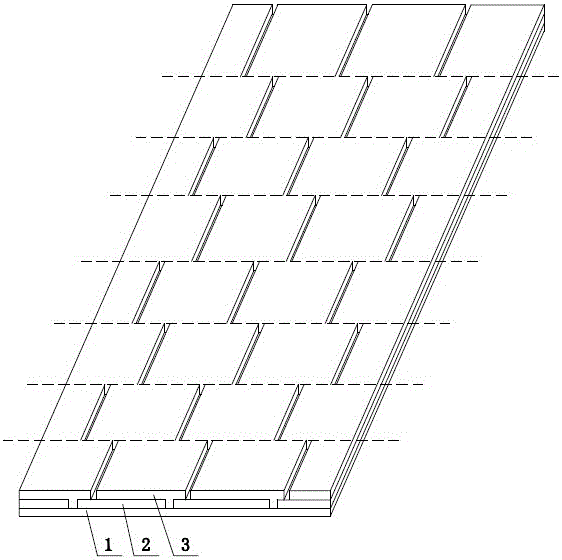

[0021] A method for increasing the series voltage of a solar cell module and effectively reducing the hot spot effect, the method is realized on the basis of the solar cell module preparation process, the steps of the method include depositing a conductive thin film layer 2 on a substrate glass 1 and scribing Scribing and depositing the photovoltaic absorbing layer 3 and scribing, depositing the back electrode layer 4 and scribing to form a series sub-battery module, the key point is: the scribing method of the conductive thin film layer 2 is: the scribing line is along the edge of the substrate glass 1 The transverse direction and the longitudinal direction are cross-cut, and the cut conductive film layer 2 forms independent conductive modules arranged in sequence by means of the transverse groove P11 and the longitudinal groove P12, and the independent conductive modules 21 of two adjacent rows of ends are connected end to end, The front electrode conductive strips arranged i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com