Method and device for position adjustment of objective lens in optical pickup head

A technology for adjusting devices and pickup heads, which is applied in the optical field, can solve problems such as reduced production efficiency, low accuracy and stability, and time-consuming, and achieve the effect of improving adjustment efficiency and ensuring accuracy and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

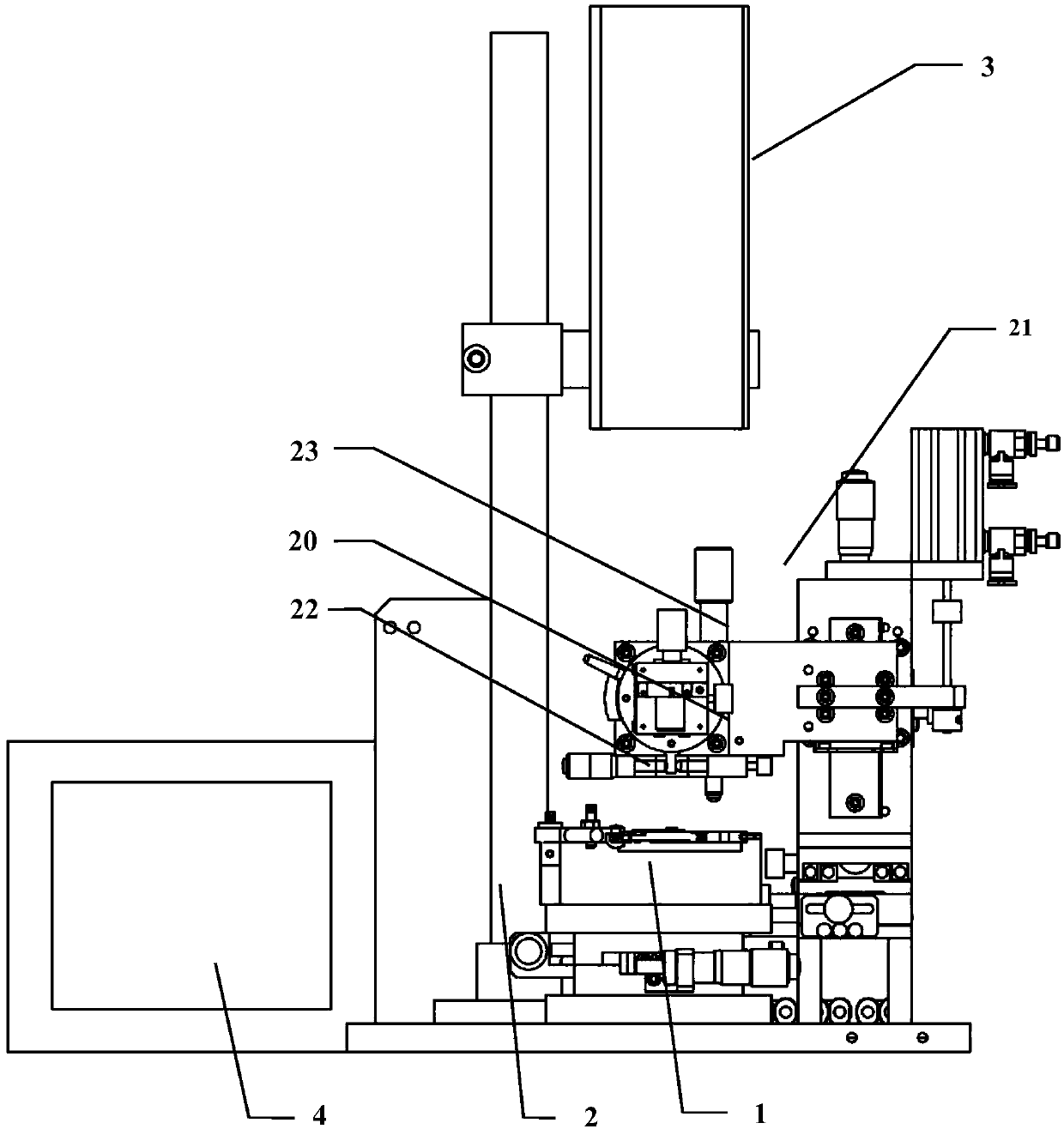

[0034] This embodiment provides a device for adjusting the position of the objective lens in the optical pickup head, the structure of the device, and the connection schematic diagram between the optical pickup head and the optical pickup head are as follows: figure 1 shown in figure 1 Among them, it includes a fixed frame 1 of the optical pickup, and a device 2 connected to the fixed frame 1 to adjust the position of the objective lens in the optical pickup, a collimator device 3 and a display 4 . Wherein the fixed frame 1 is used to fix the optical pickup head, the fixed frame 1 is installed on the above-mentioned device 2 through the slide table base in the horizontal mode of the optical pickup head, and the position of the optical pickup head is adjusted by the slide table base , make the position of the optical pickup objective lens consistent with the position of the adjustment guide frame 20 front, back, left, and right.

[0035] In practical applications, the above-me...

Embodiment 2

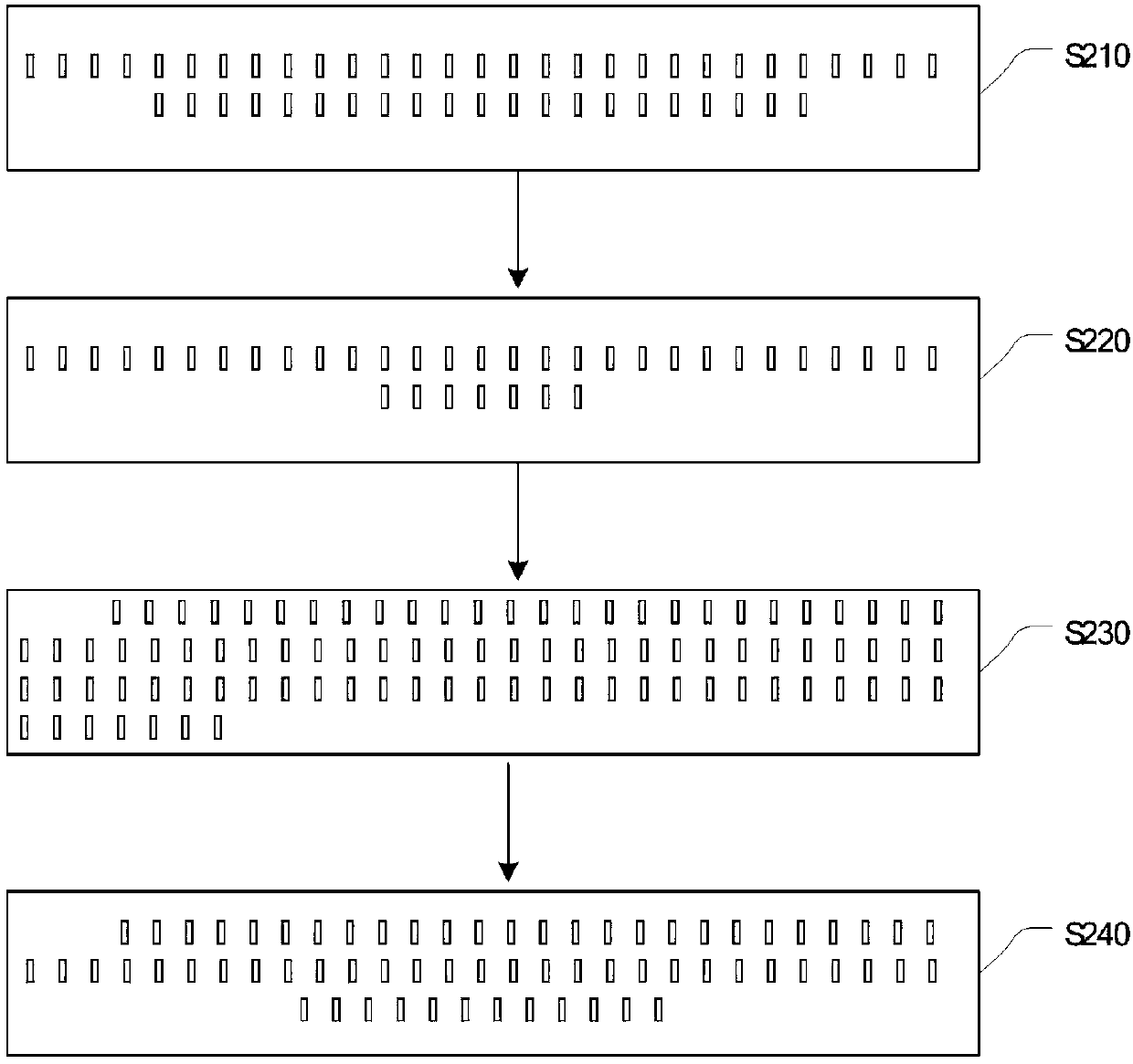

[0048] Based on the above figure 1 Described device, the processing flow of a kind of method that this embodiment provides to the objective lens in the optical pick-up position adjustment is as follows figure 2 As shown, the following processing steps are included:

[0049] Step S210, setting the device for adjusting the position of the objective lens in the optical pickup head including the objective lens guide frame, height adjustment knob, tangential adjustment device and radial adjustment device, the device can be connected with the fixed mount of the optical pickup head, Also included in the optical pickup is a collimator device and a display.

[0050] Step S220 , when the objective lens in the optical pickup head moves toward the optical disc, contact the objective lens guide frame with the objective lens.

[0051] After the focus servo of the actuator in the optical pickup head is connected to a certain working voltage, the objective lens holder of the actuator has t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com