Safety monitoring method for internal diaphragm of lithium-ion power battery

A power battery and safety monitoring technology, applied in the investigation phase/state change and other directions, to achieve the effect of breaking through the technical bottleneck and improving the identification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the embodiments and accompanying drawings.

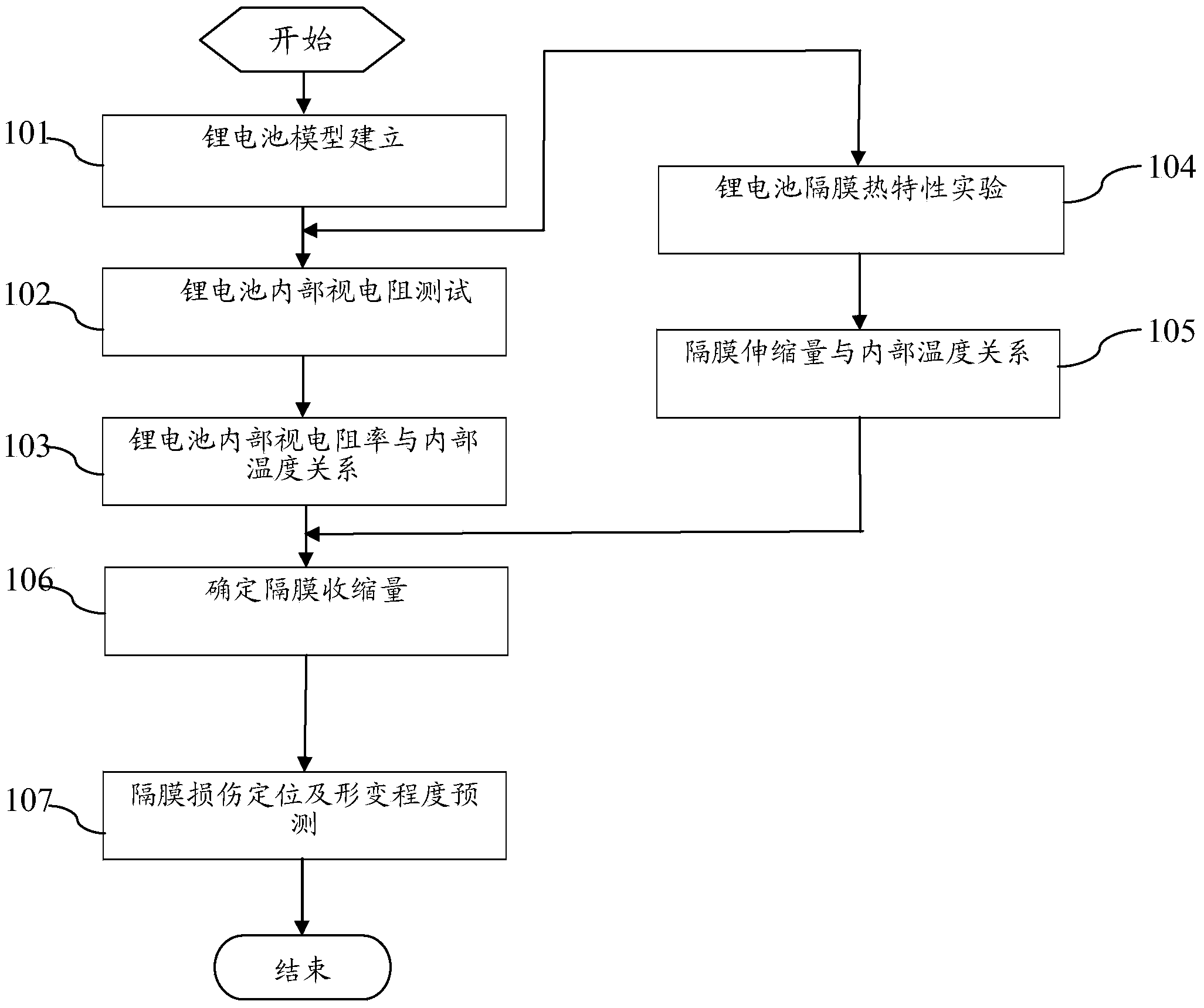

[0025] Such as figure 1 As shown, it is a flow chart of the online safety detection method for the internal diaphragm of the lithium-ion power battery, and the method includes:

[0026] Step 101 establishes a lithium battery model.

[0027] Step 102 tests the internal apparent resistivity of the lithium battery to obtain the distribution of the internal apparent resistivity of the lithium ion power battery.

[0028] Step 103 obtains the relationship between the internal temperature of the lithium battery and the internal apparent resistivity.

[0029] In the implementation of the above steps 101-103, the ERT sensor is pasted on the surface of the power battery, and by providing excitation to the electrode array on the battery surface, the uneven ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com