Flow control sleeve cylinder set

A technology of flow control and sleeve group, which is applied in the direction of sliding valves, engine components, mechanical equipment, etc., and can solve problems such as difficult construction, failure to function, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

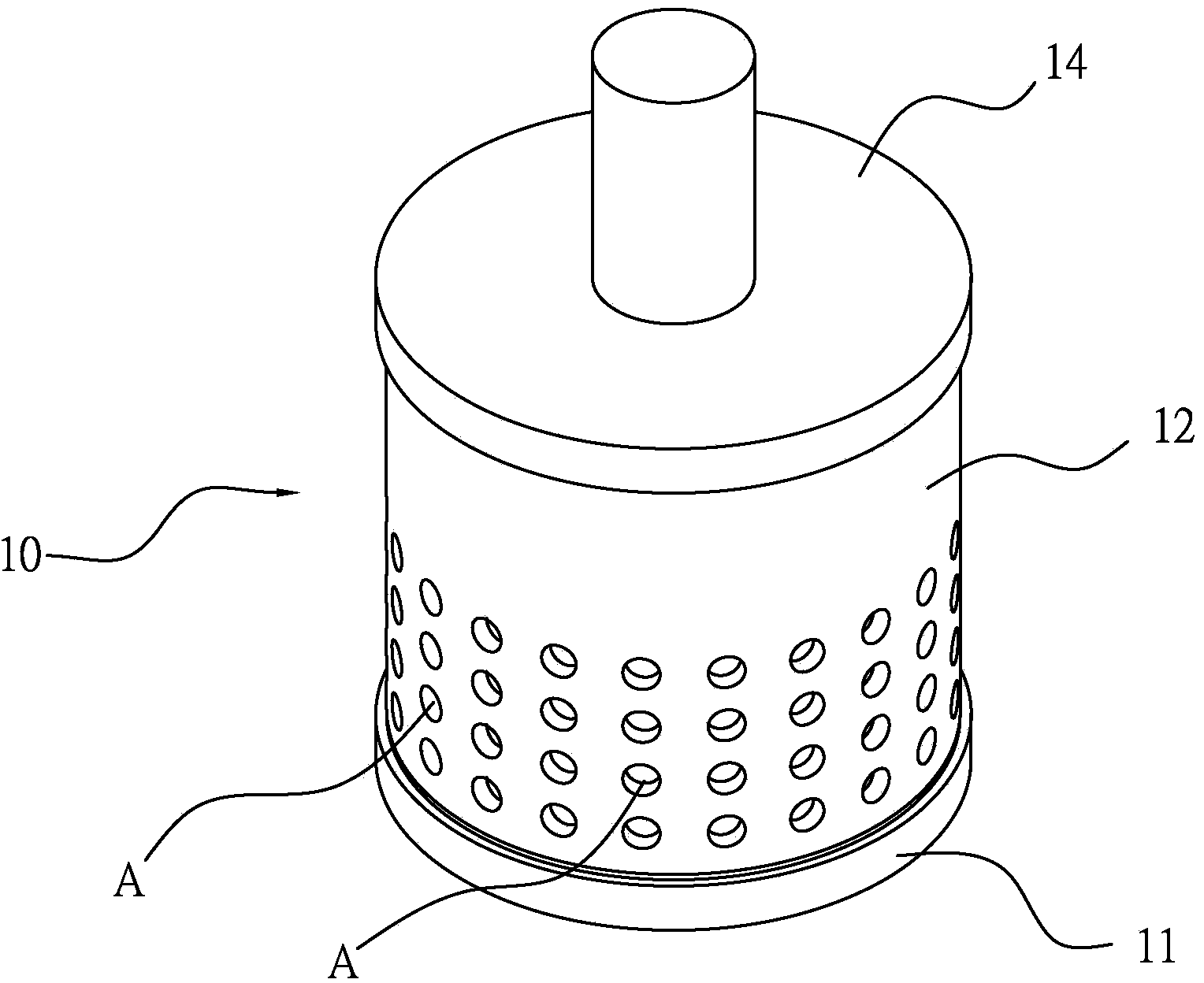

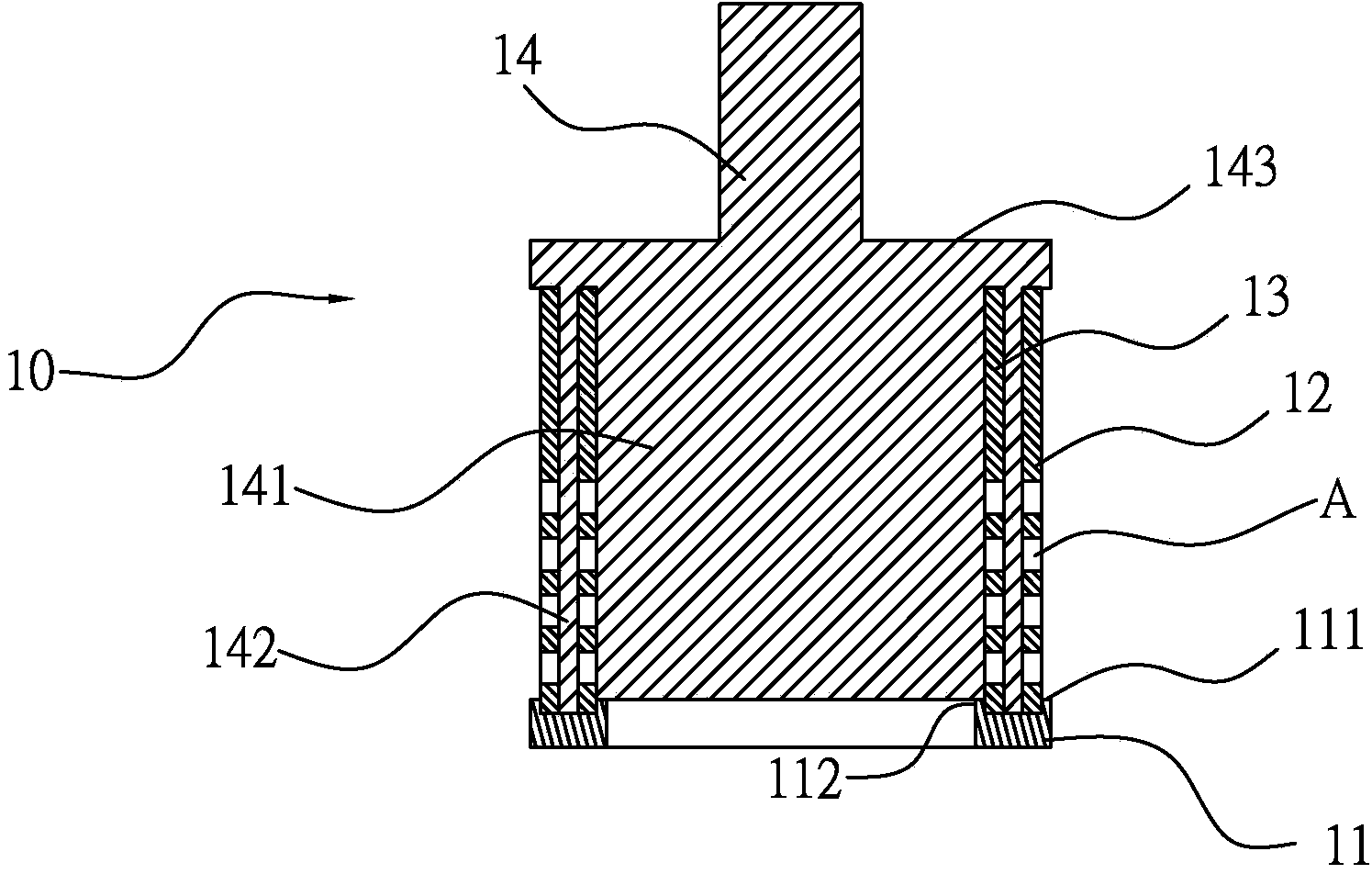

[0032] see figure 1 and figure 2 , is a schematic diagram of the appearance of the flow control sleeve set in the best embodiment of the present invention and an exploded view of components. As shown in the figure, the main structure of the flow control sleeve set 10 of this embodiment includes a base 11, a first sleeve 12, a The second sleeve 13 and a valve plug 14 .

[0033] In this embodiment, the base 11 is located at the bottom of the flow control sleeve set 10, and its appearance is roughly circular, that is, a through flow channel 113 is formed in the middle of the base 11, and the outer edge and the inner surface of the upper surface of the base 11 A first flange 111 and a second flange 112 respectively protrude upward from the edge, respectively used for positioning the first sleeve 12 and the second sleeve 13 combined on the base.

[0034] The first sleeve 12 and the second sleeve 13 are both hollow cylinders, and are respectively provided with at least two perfor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com