Steel truss girder assembling scaffold used in construction of steel-concrete composite truss girders

A technology of composite trusses and steel truss beams, applied in the direction of erecting/assembling bridges, bridges, bridge materials, etc., can solve the problems of large elastic deformation of supports, inability to bear the concentrated stress of steel beam nodes, unfavorable accurate positioning of steel beam nodes, etc., to achieve The force is simple, it is conducive to accurate positioning, and the effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with accompanying drawing and non-limiting embodiment:

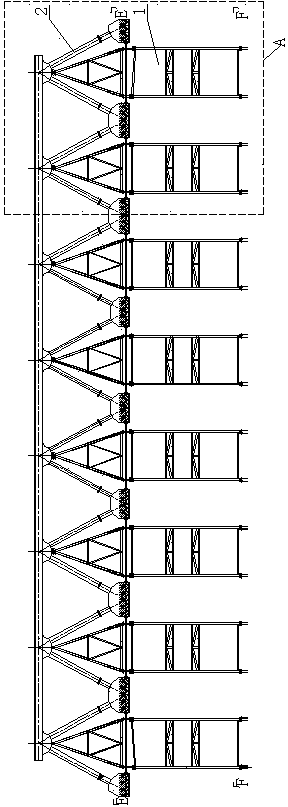

[0025] As shown in the attached picture, the Shaoguan Zhenjiang Bridge on the decommissioning line has a total length of 2.3km, 1-88m steel-concrete composite truss girders span 13# to 14#, and cross the Beijing-Guangzhou Railway up and down lines, with an intersection angle of 30 °, located on the transitional curve with a curve radius of R=800m. This project adopts the construction method of lateral cast-in-place and dragging and moving laterally.

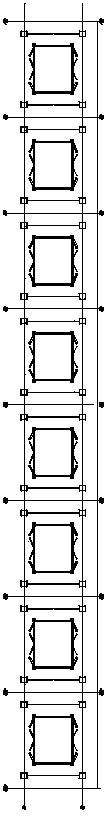

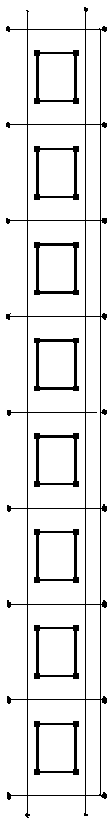

[0026] The construction of steel-concrete composite truss girders is carried out by erecting full-wall brackets and steel truss girder assembly brackets on the right side of the bridge. The full hall bracket is used for pouring concrete, and the steel truss beam assembly bracket is used for assembling the steel truss beam 2. The assembled support of the steel truss girder includes eight assembled ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com