Efficient Locomotive Bolt Fastening Device

A bolt fastening device and locomotive technology, applied in the direction of laying tracks, roads, tracks, etc., can solve the problems of high work intensity and low efficiency, and achieve the effects of flexible use, convenient operation and reduced work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

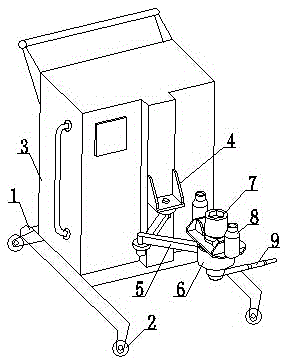

[0013] like figure 1 It is a structural schematic diagram of the present invention, a high-efficiency locomotive bolt fastening device, including a vehicle frame 1, wheels 2, lifting box 3, balance platform 4, telescopic arm 5 and fastening head 6, and the wheel 2 is located at the bottom of the vehicle frame 1, The lifting box 3 is installed on the top of the vehicle frame 1, the balance platform 4 is connected on the lifting box 3, the fastening head 6 is connected with the balancing platform 4 through the telescopic arm 5, the fastening head 6 is provided with a torque sleeve 7, a reaction force bar 8 and tighten the gun 9. The side of balance platform 4 is a right triangle, and is slidably connected on the guide rail of lifting box 3 . The telescopic arm 5 is a rotating link structure, and its two ends are respectively connected to the balance platform 4 and the fastening head 6 in rotation. The torque sleeve 7 and the tightening gun 9 are located on the top and bottom o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com