Novel casting cooling device

A cooling device and casting technology, which is applied in the field of casting production, can solve the problems of high temperature for a long time and the heat of castings cannot be dissipated in time, and achieve the effects of convenient operation, shortened cooling time, and reasonable structure settings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

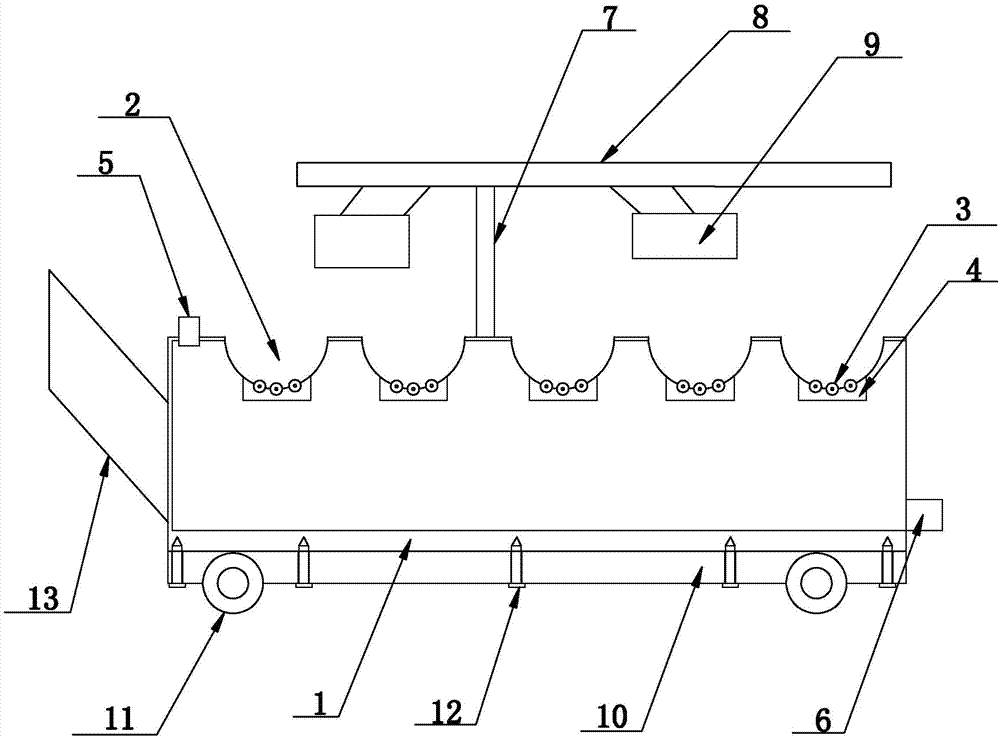

[0015] see figure 1 , a novel cooling device for castings disclosed by the present invention, comprising a water tank 1, a plurality of arc-shaped grooves 2 are arranged on the upper surface of the water tank 1, and at least one casting roller 3 is arranged at the bottom of each arc-shaped groove 2, said The inner cavity of the water tank 1 is located at the bottom of each arc-shaped groove 2 and is fixedly provided with a casting roller sealing chamber 4, and the left end of the upper end surface of the water tank 1 is fixedly provided with a water filling port 5, and the lower end of the right end surface of the water tank 1 is fixedly provided with a drain pipe 6 , the upper end surface of the water tank 1 is vertically fixed with a support rod 7, the upper end of the support rod 7 is fixed with a cross bar 8, and the cross bar 8 is fixed with a blower 9, and the air outlet of the blower 9 faces the arc groove 2 Opening setting.

[0016] Preferably, a row of arc-shaped gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com