4D breathable vamp and shoe

A technology for breathable shoes and vamps, which is applied in the direction of shoe uppers, footwear, boot legs, etc., which can solve the problems of easy deformation of vamps, no three-dimensional effect of vamps, complicated process, etc., and achieve strong and novel three-dimensional visual effects , wear soft and comfortable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

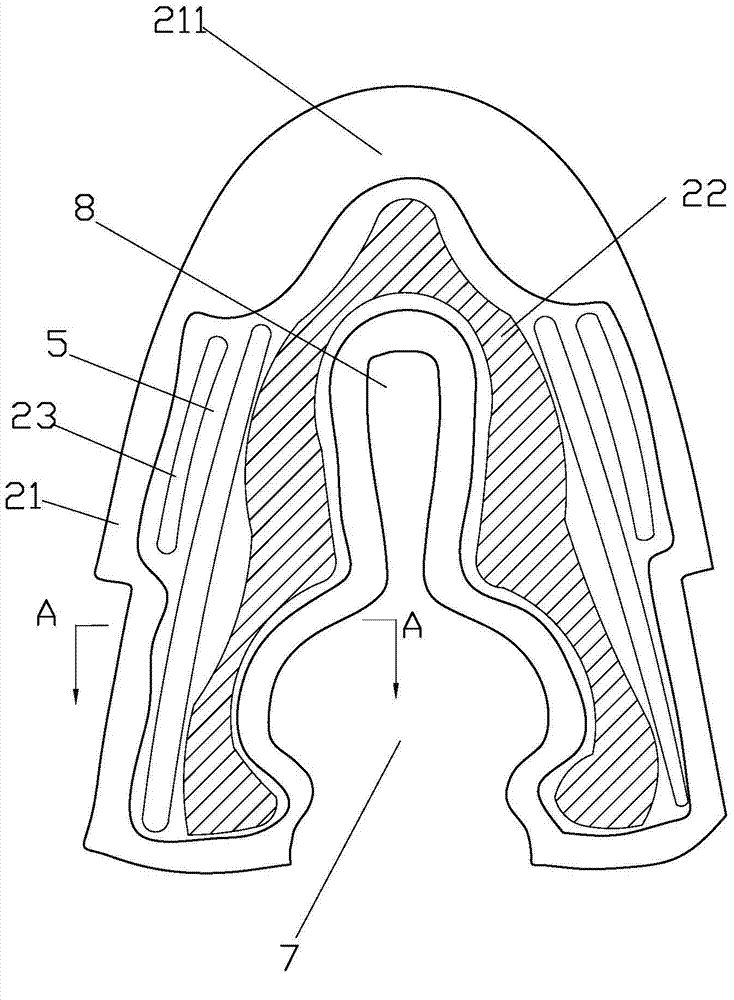

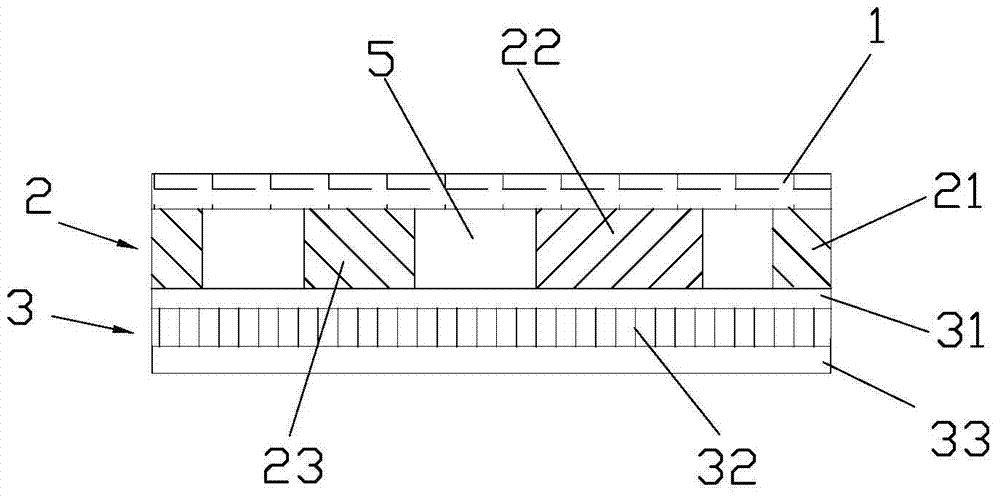

[0029] Embodiment 1: as figure 1 and figure 2 As shown, a 4D breathable vamp includes a vamp body. The vamp body is in the shape of a semi-boat with a large back and a small front. The middle part of the body is provided with a tongue portion 8, the tongue portion 8 is “n” shaped, and the tongue portion 8 is connected to the mouth portion 7 in a circular arc transition. The vamp body includes a surface layer 1, a backing layer 2 and a bottom layer 3, the surface layer 1, the backing layer 2 and the bottom layer 3 are bonded together, the surface layer 1 is a whole gauze cloth, and the gauze cloth is In a single layer, the diameter or width of the mesh is larger than the interval between the meshes, and the perspective is very good. The backing layer 2 is a knitted fabric with single-color or pattern printing, the backing layer 2 is a knitted fabric containing polyester, the density of the knitted fabric is greater than that of the surface layer 1 and the bottom layer 3, and...

Embodiment 2

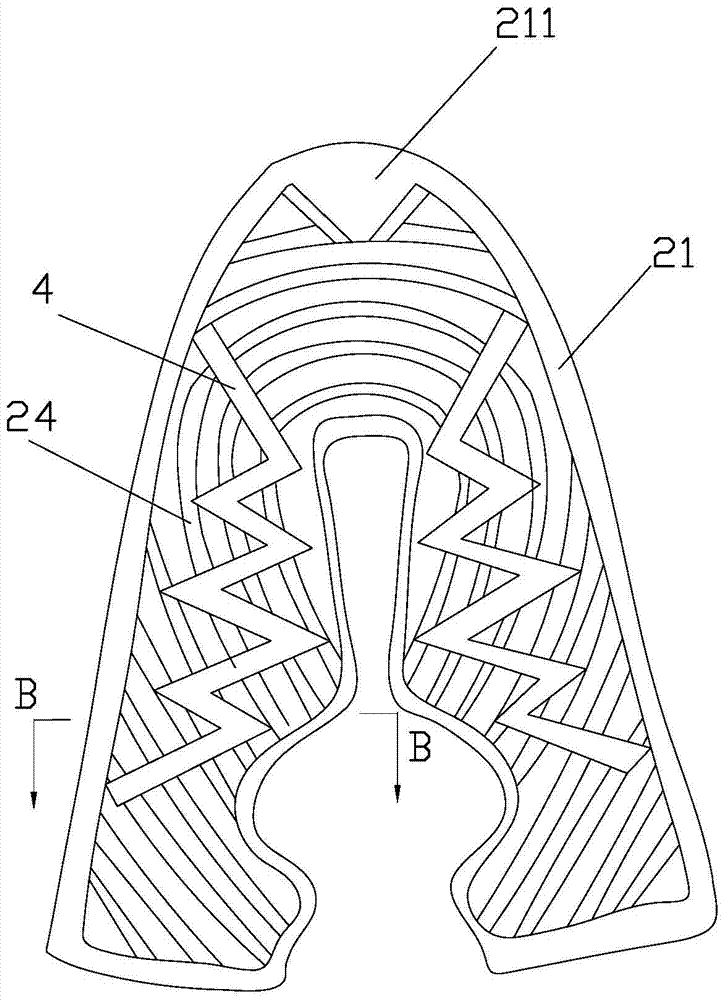

[0032] Embodiment 2: as image 3 and Figure 4 As shown, a 4D breathable vamp includes a vamp body, and the structure and mutual positional relationship of the components of the vamp body are basically the same as in Embodiment 1, except that the lining block is an arc-shaped lining strip 24. Both sides are also symmetrically provided with reinforcement blocks 4, the reinforcement blocks 4 are a plurality of connected Z shapes, the reinforcement blocks 4 are bonded between the surface layer 1 and the backing layer 2, and the reinforcement blocks 4 cover multiple arcs. Shaped foil strip 24. The reinforcing block 4 is superimposed on the backing layer 2 to make the vamp more rigid, and the reinforcing block 4 is bonded to the arc-shaped backing bar 24 that it straddles, which improves the integrity of the structure and enriches the three-dimensional sense of hierarchy.

Embodiment 3

[0033] Embodiment 3: as Figure 5 and Figure 6 As shown, a 4D breathable vamp includes a vamp body. The vamp body is in the shape of a semi-boat with a large back and a small front. The middle part of the body is provided with a tongue portion 8, the tongue portion 8 is “n” shaped, and the tongue portion 8 is connected to the mouth portion 7 in a circular arc transition. The vamp body includes a surface layer 1, a backing layer 2 and a bottom layer 3, the surface layer 1, the backing layer 2 and the bottom layer 3 are bonded together, the surface layer 1 is a whole gauze cloth, and the gauze cloth is In a single layer, the diameter or width of the mesh is larger than the interval between the meshes, and the perspective is very good. The backing layer 2 is a knitted fabric with monochrome or pattern printing, the backing layer 2 is a knitted fabric containing polyester, the density of the knitted fabric is greater than that of the surface layer 1 and the bottom layer 3, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com