Methods and apparatuses for drying electronic devices

A technology of electronic devices and equipment, applied in the direction of electric heating devices, dry gas arrangement, lighting and heating equipment, etc., can solve the problems of inoperable equipment and difficult disassembly by users

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

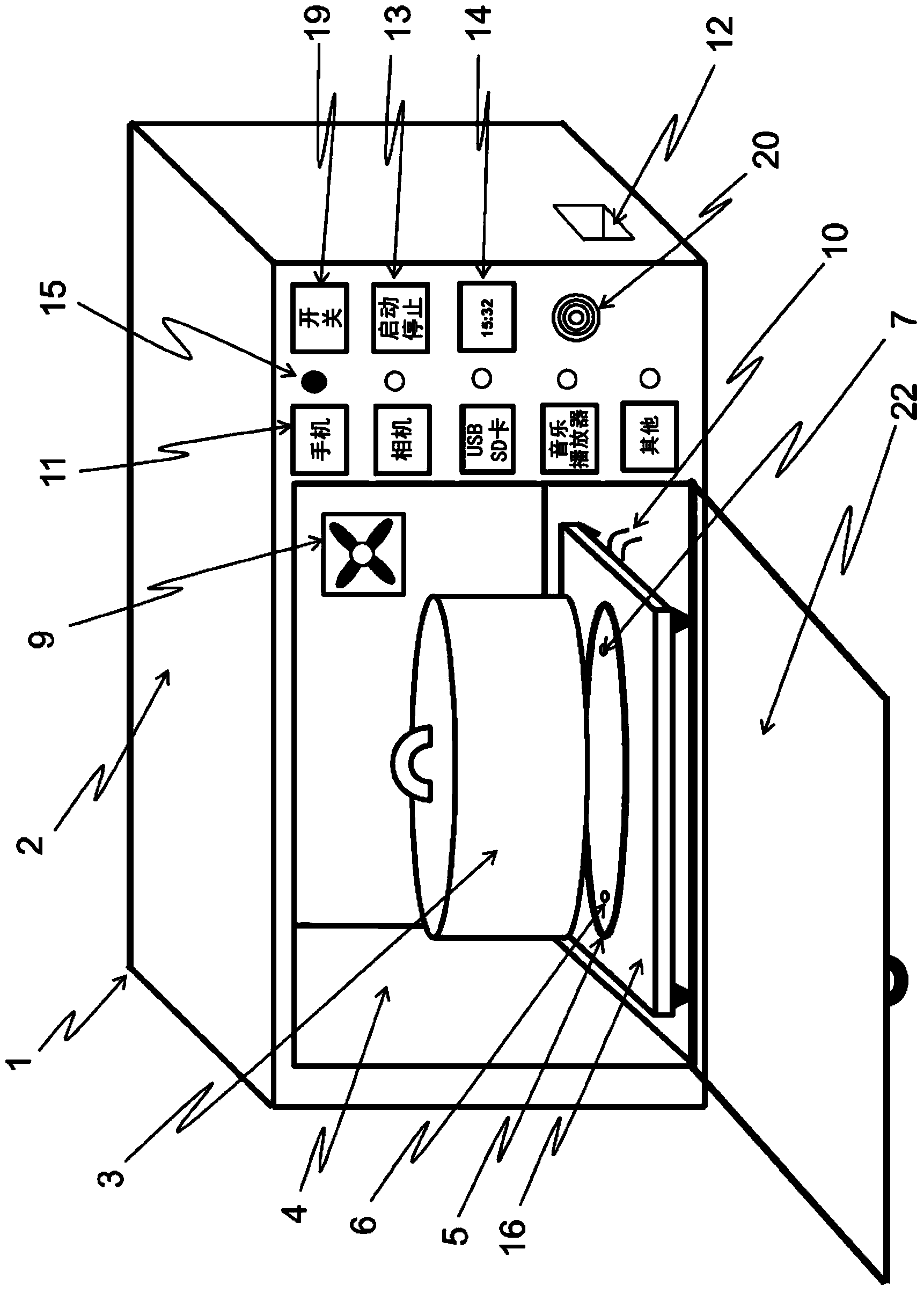

Method used

Image

Examples

other Embodiment approach

[0092] Other embodiments include the aforementioned X1, X2, X3, X4, X4, Features described in any of X5, X6 and X7:

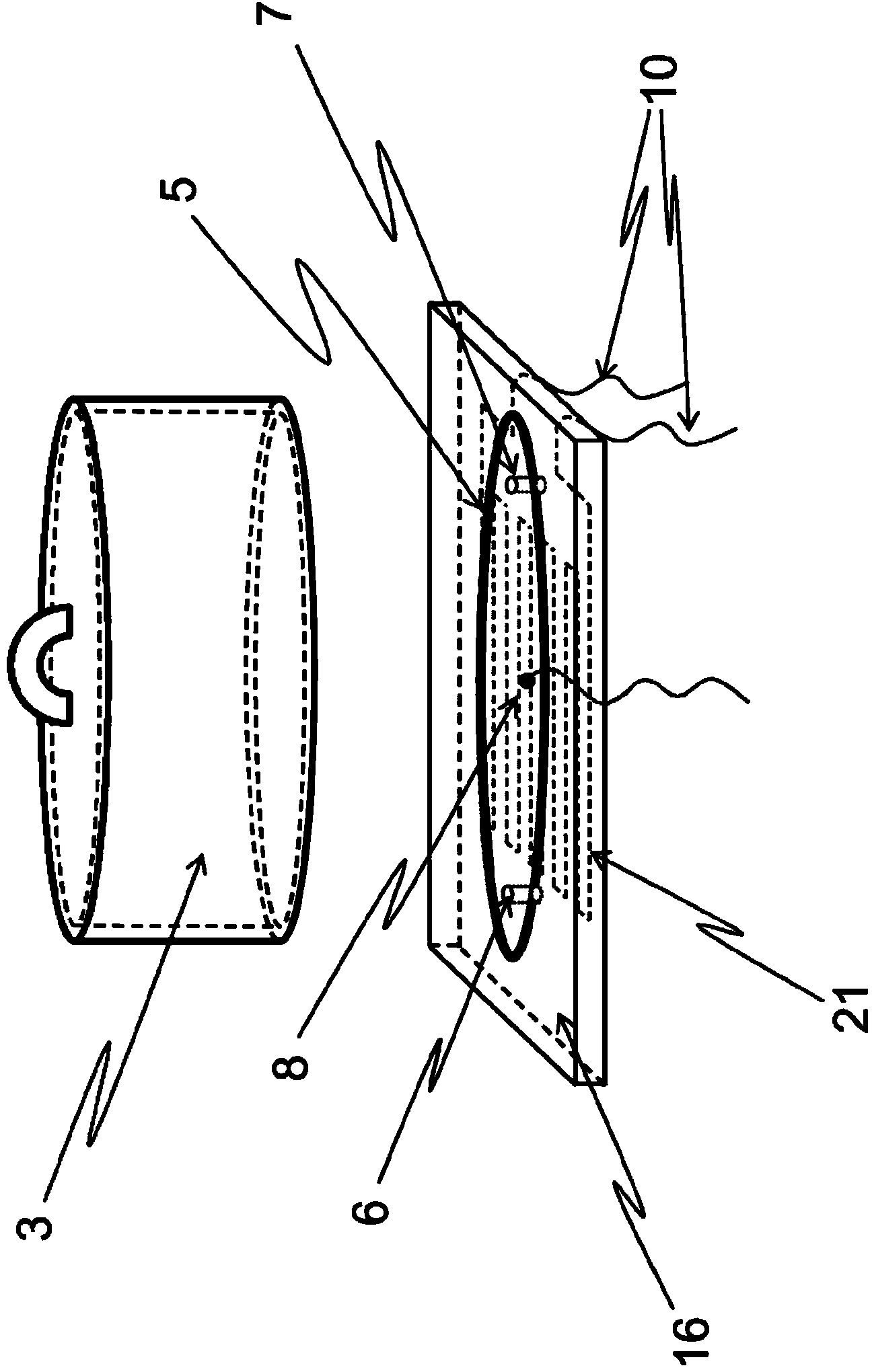

[0093] Regenerative dryer unit for automatic drying of desiccant.

[0094] UV germicidal lamp unit for disinfection of portable electronic devices.

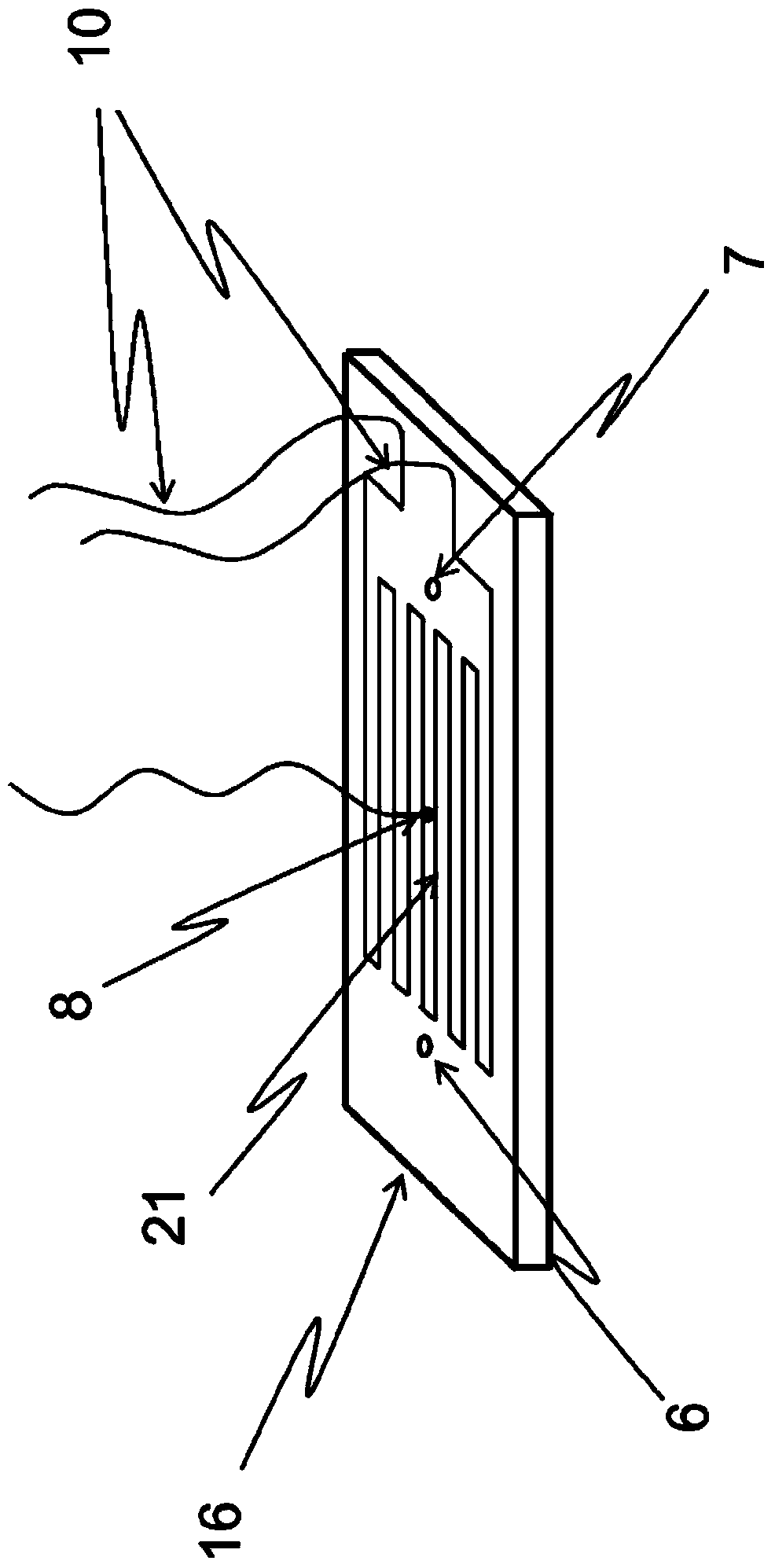

[0095] Wherein said heated conductive platen comprises a thermal foil heater laminated to a metal conductive platen.

[0096] Wherein the heating conduction platen hot foil heater is between 25 watts and 1000 watts.

[0097] Wherein the heating conduction platen uses a temperature feedback sensor.

[0098] Wherein the surface area of the heating conduction platen is between 4 square inches and 1500 square inches.

[0099] Wherein the heated conduction platen is also used as a convection oven heater to heat the exterior of the vacuum chamber.

[0100] Wherein the convection oven is used to heat the exterior of the vacuum chamber to minimize condensation inside the vacuum chamber once evaporation occurs. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com