Continuous plating apparatus

An electroplating device and electroplating solution technology, applied in the direction of the plating tank, etc., can solve the problems of low electroplating efficiency, difficulty in applying high current, etc., achieve high electroplating efficiency, reduce the overall equipment size, and maximize the effect of space efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Hereinafter, the present invention will be described in detail with reference to the accompanying drawings.

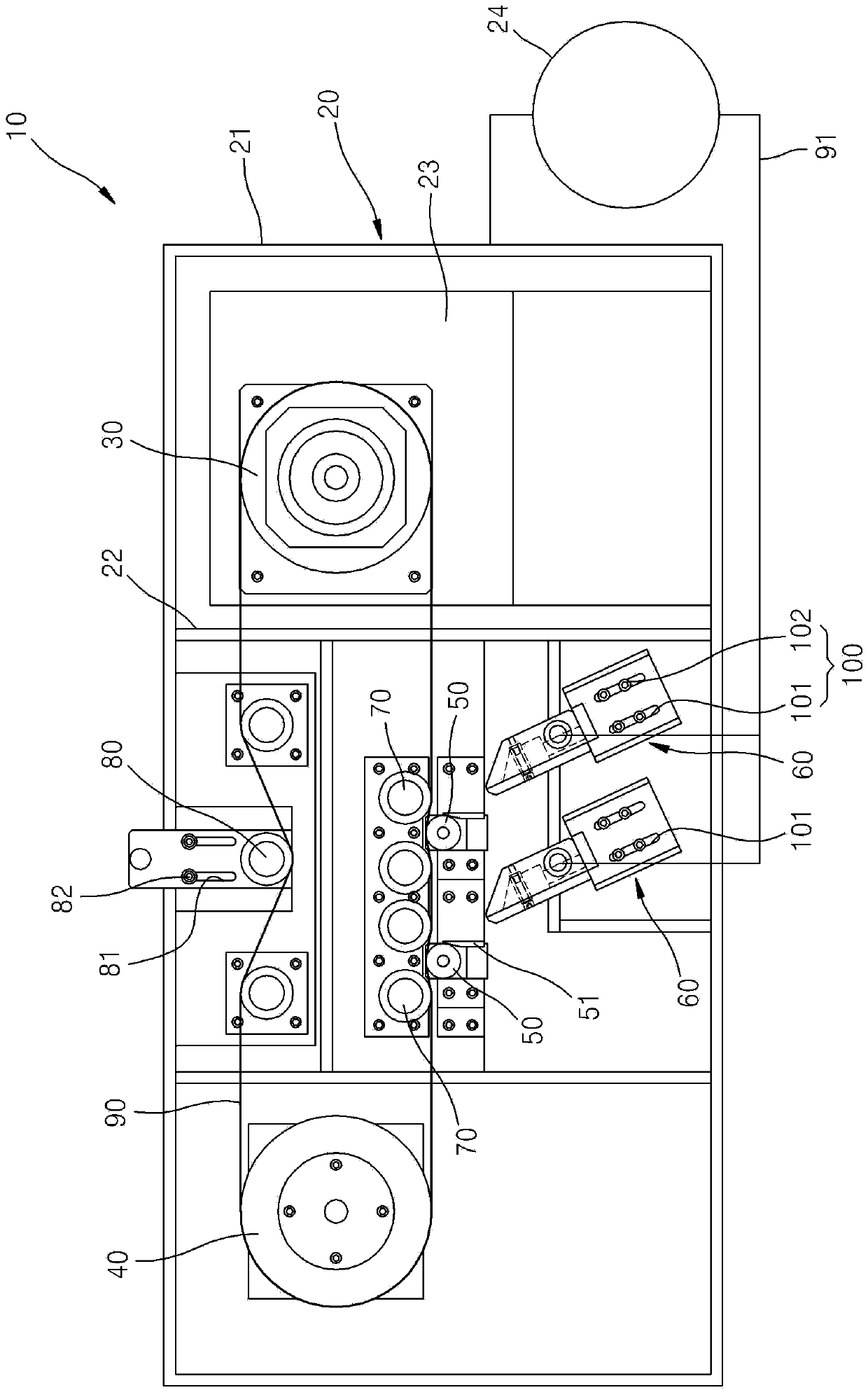

[0022] The continuous electroplating device 10 according to an embodiment of the present invention forms a predetermined electroplating layer on the surface of the electroplating target 90, wherein the electroplating target 90 has a predetermined width and extends in a predetermined direction; the continuous electroplating device 10 can be continuously formed on the surface of the electroplating target 90 Plating. Specifically, the continuous plating apparatus 10 uses a printing method to form a plating layer on a plating target 90 (elastic substrate or rigid substrate).

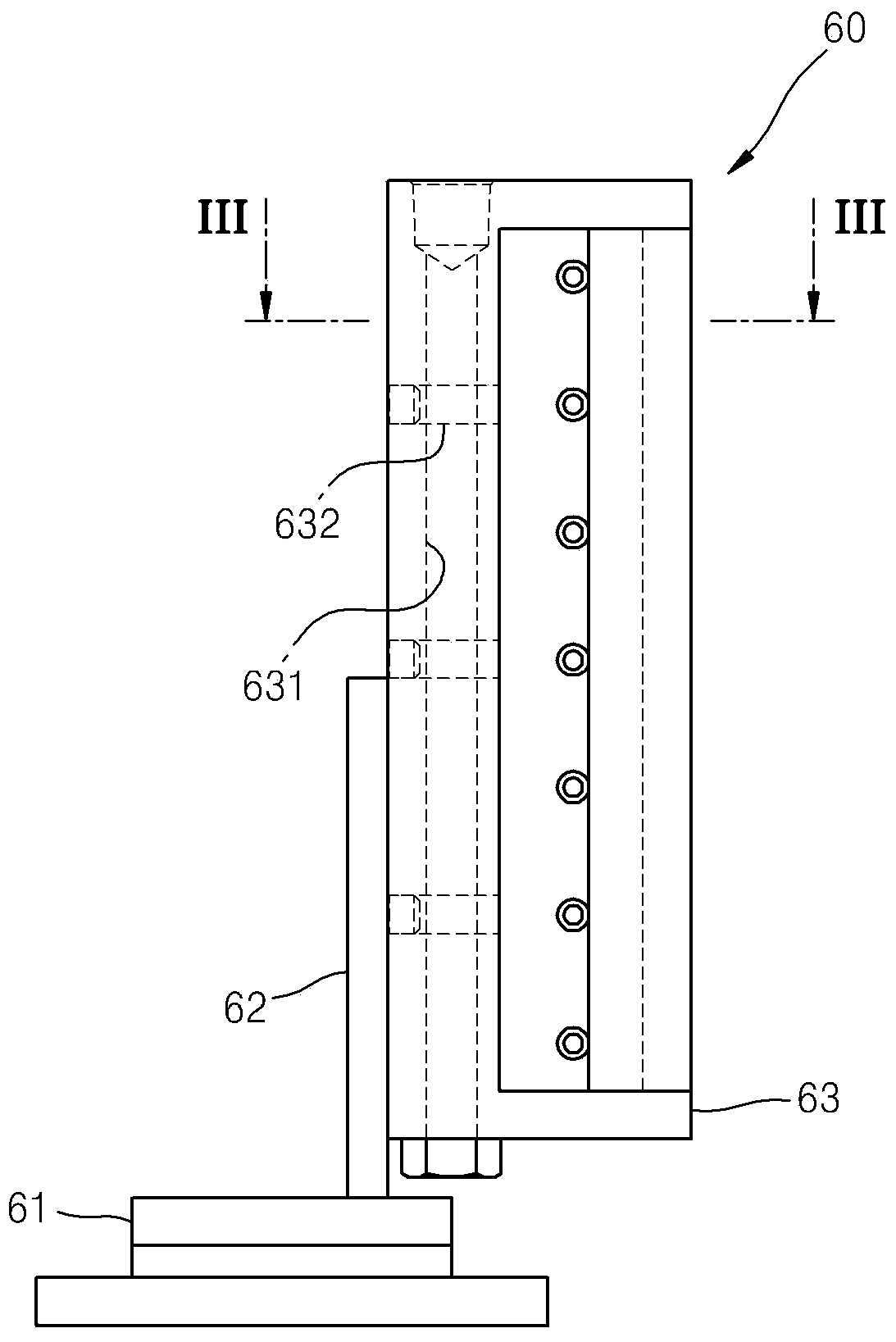

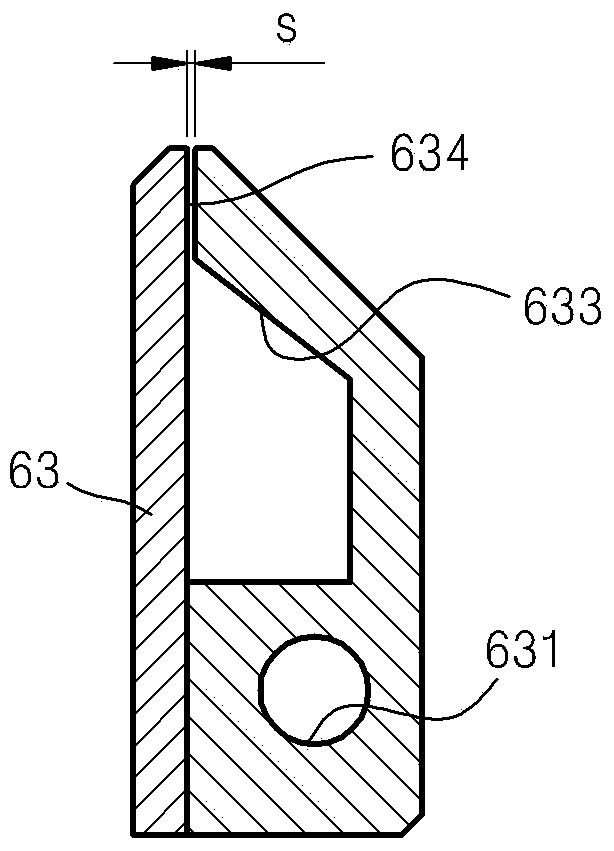

[0023] The continuous plating apparatus 10 includes a frame 20 , a driving roll 30 , a driven roll 40 , a negative roll 50 , a positive nozzle unit 60 , a tension maintaining roll 70 and a tension supply roll 80 .

[0024] The frame 20 is the main body of the continuous electroplating device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com