Segmented led drive circuit

An LED driving, segmented technology, applied in the field of electronics, can solve the problems of increased power consumption of line circuits, poor current consistency, low PF total harmonic distortion, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to describe the technical content of the present invention more clearly, further description will be given below in conjunction with specific embodiments.

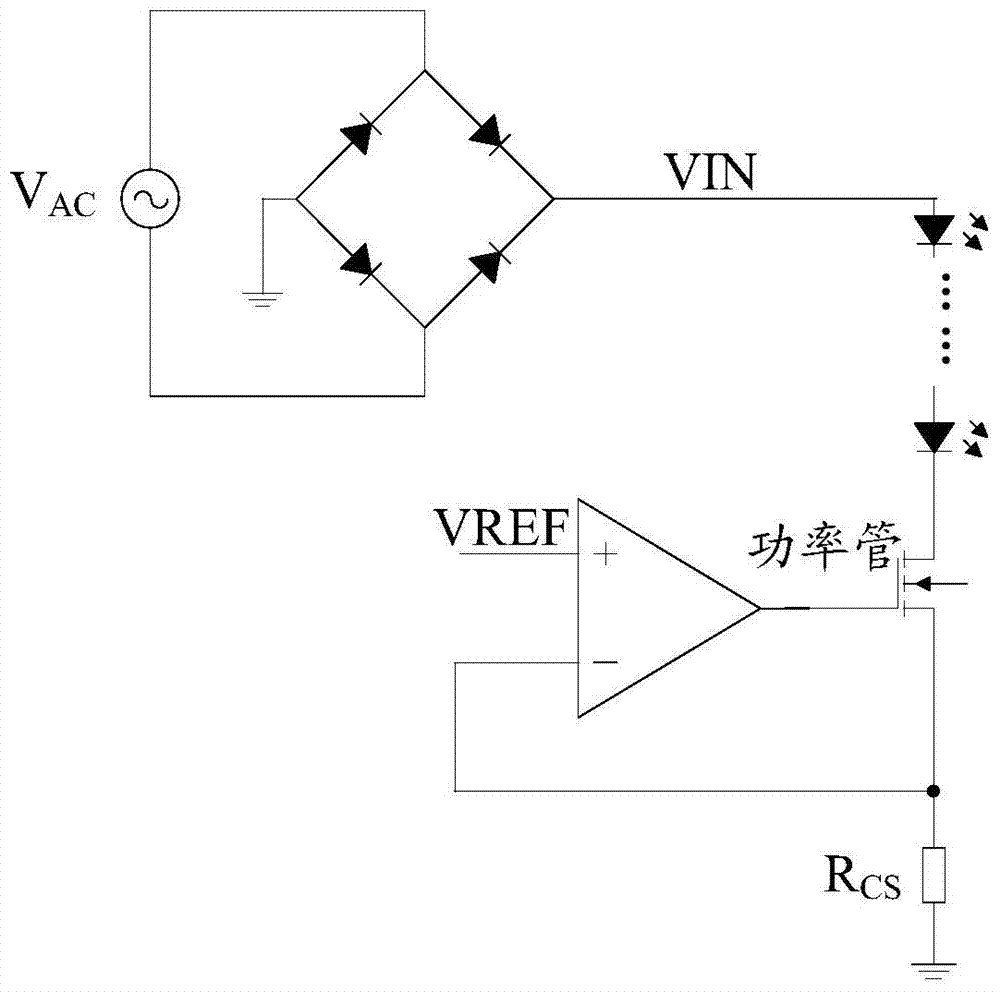

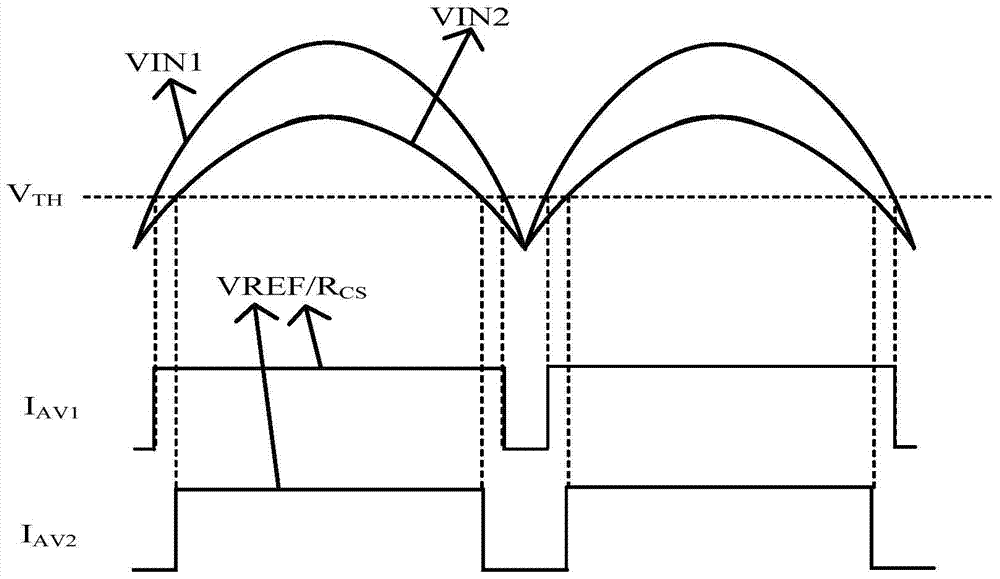

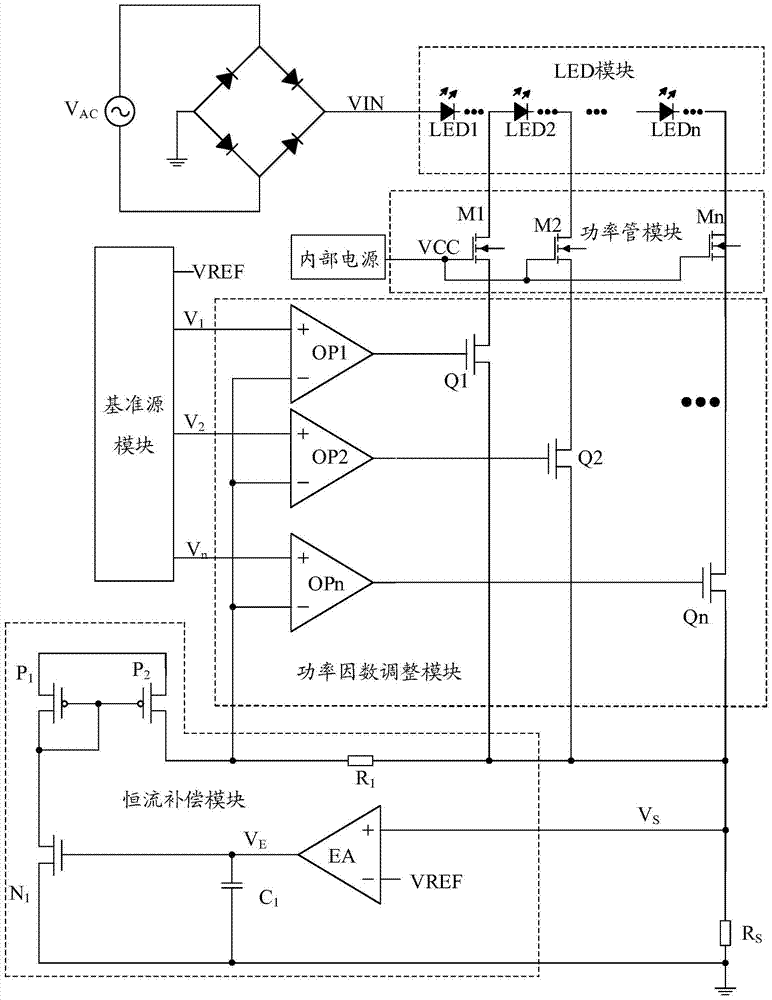

[0030] see Figure 3 to Figure 4 As shown, the segmented LED drive circuit of the present invention includes:

[0031] LED modules, which include several strings of LED lights connected end to end;

[0032] A power tube module, which includes a number of power tubes corresponding to the number of LED light strings, and each power tube corresponds to only one LED light string;

[0033] A power factor adjustment module, which includes a number of voltage comparison units corresponding to the number of power tubes, and each voltage comparison unit corresponds to only one power tube;

[0034] A reference source module, which includes several voltage output terminals and a reference signal output terminal corresponding in number to the voltage comparison unit;

[0035] The input end of the rectification and f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com