Composite insulator V-shaped overhung string for overhead transmission line

A technology of overhead transmission lines and composite insulators, applied in the direction of suspension/strain insulators, etc., can solve the problems of composite insulator V-shaped suspension series assembly form is not perfect, and achieve the effect of solving torsion, reducing mechanical load, and avoiding axial torsion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

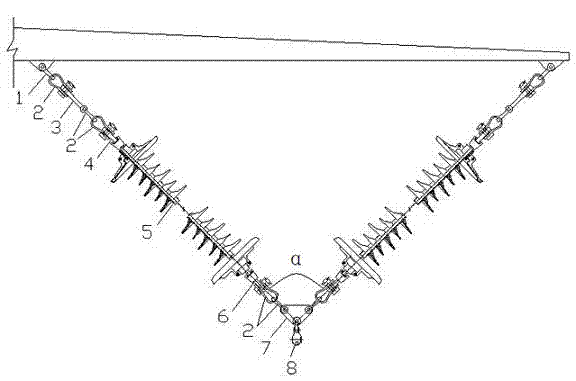

[0011] Example 1: A V-shaped suspension string of composite insulators for overhead transmission lines (see figure 1 ), which includes connecting fittings and composite insulator strings. The connecting fittings are composed of a connecting plate 7 and a suspension clamp 8. The connecting plate 7 is a 3-hole connecting plate. Each hole is respectively connected to a composite insulator string, and the two composite insulator strings are suspended in a V shape with an included angle α of 80° to 100°. Each composite insulator string includes in order from the grounding end to the live end: 1 pair of inner arc U-rings of the tower 1, 1 pair of ordinary inner arc U-rings 2, 1 pair of extension rods 3, 2 pairs of inner arcs connected by rings Arc U-shaped ring 2, 1 pair of ball head hanging ring 4, ball socket, composite insulator with ball head structure 5, W-shaped bowl head hanging plate 6, 2 pairs of inner arc U-shaped rings connected by rings and rings 2, joint towers Inner a...

Embodiment 2

[0012] Example 2: A V-shaped suspension string of composite insulators for overhead transmission lines (see figure 2 ), its structure is basically the same as that of Embodiment 1, the difference is that the connecting plate 7 is a rectangular connecting plate with 4 holes, and the lower end hangs a double-split wire suspension clamp 8.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com