Preventative device maintenance method based on dynamic reliability

A preventive and reliable technology, applied in the field of preventive maintenance of equipment, which can solve problems such as lack of reliability data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0043] This embodiment is the equipment preventive maintenance plan information management system established by Sinopec Wuhan Branch for more than 2,000 machines and pumps in the whole plant.

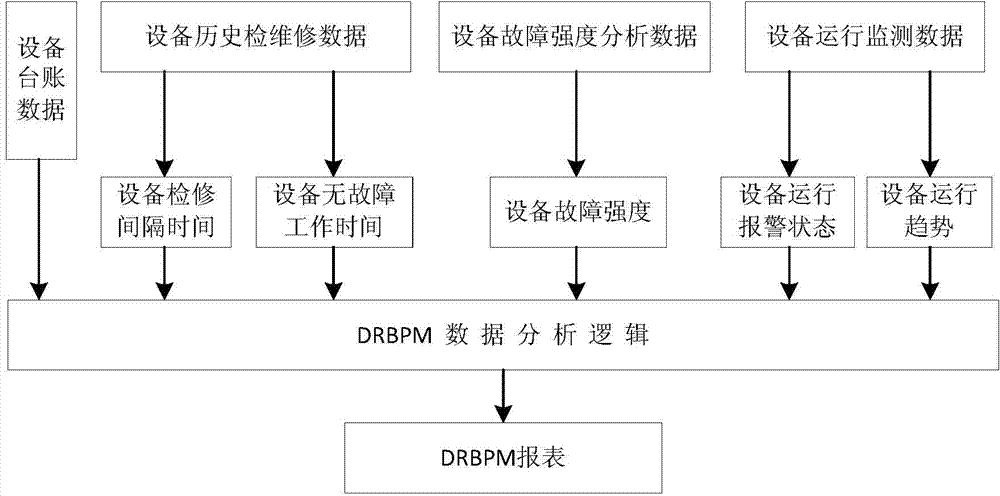

[0044] The sources of the basic equipment data used are:

[0045] (1) The equipment account data comes from the EM (Equipment Management) system of Sinopec Corporation;

[0046] (2) The historical inspection and maintenance data of the equipment comes from the EM system of Sinopec Corporation;

[0047] (3) The analysis data of equipment failure intensity is provided by Sinopec Wuhan Branch;

[0048] (4) The equipment operation monitoring data is associated with the equipment monitoring platform of Sinopec Wuhan Branch to provide data access interface.

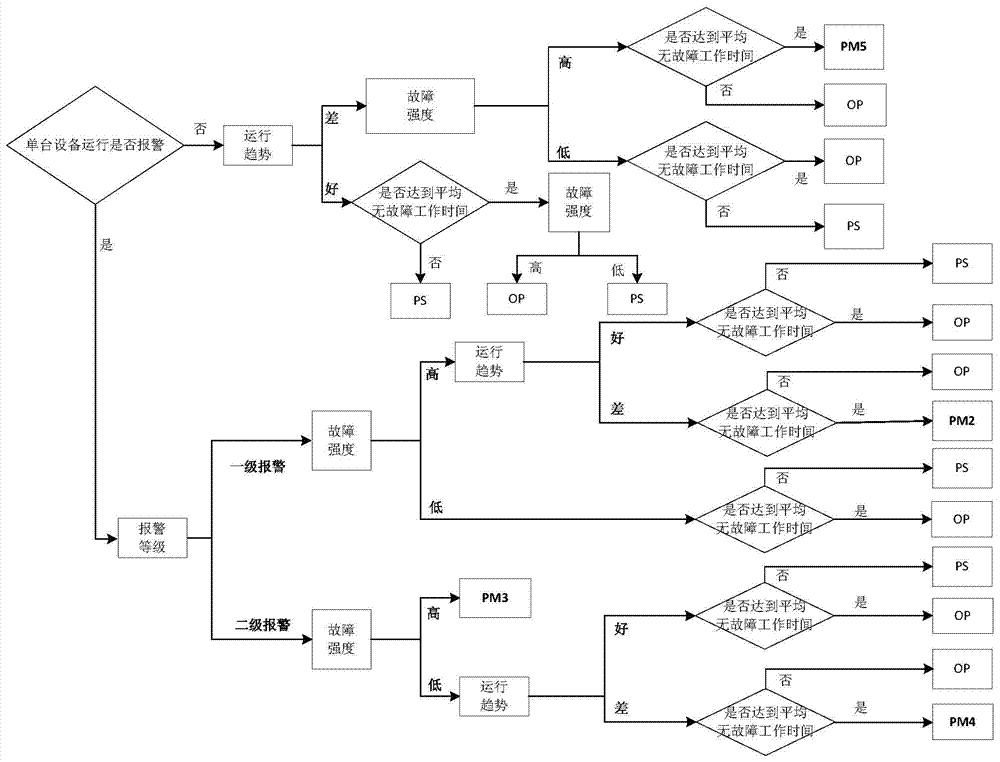

[0049] Under normal circumstances, there are two measuring points for the state value L of the bearing of the pump equipment, that is, the front end L value and the rear end L value; the vibration value V has five measuring points, na...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com