A back support device for a large-aperture mirror

A large-diameter mirror and back support technology, applied in installation, optics, instruments, etc., can solve the problems of surface shape accuracy requirements and large radial volume of optical components, and achieve easy maintenance or replacement, reliable positioning and adjustment structure, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

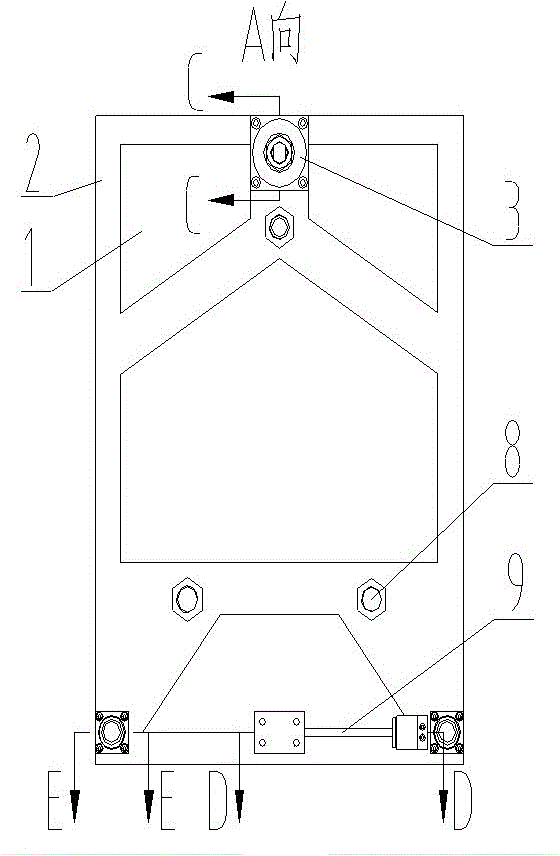

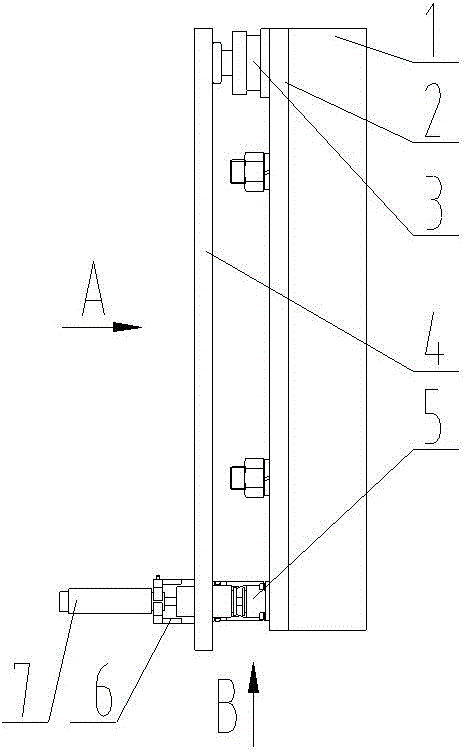

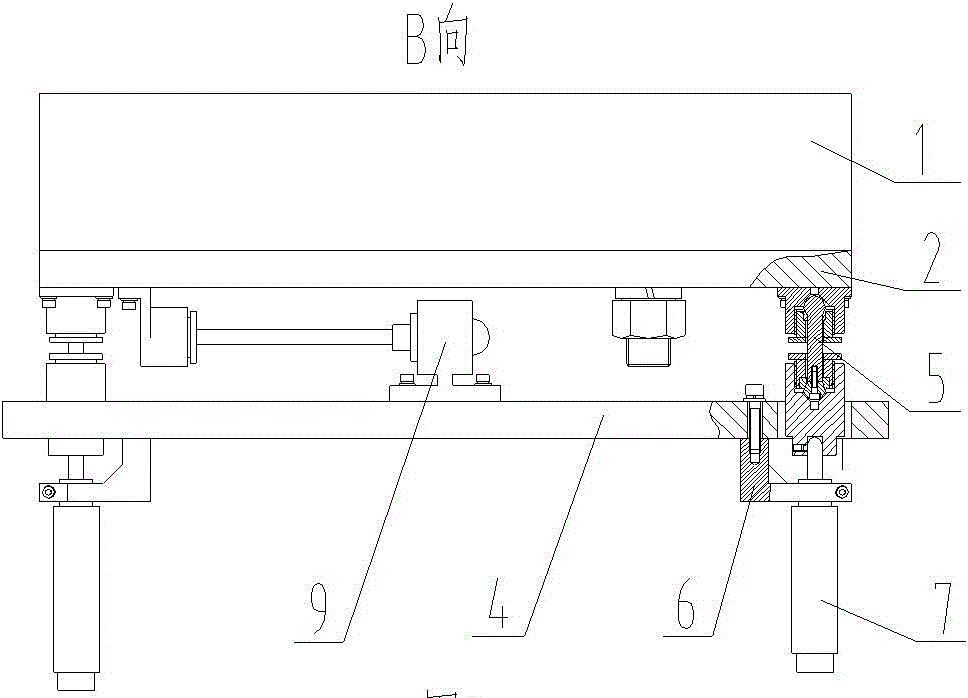

[0025] figure 1 It is a structural schematic diagram of a back support device for a large-diameter reflector in the form of a spherical joint bearing of the present invention, figure 2 yes figure 1 View from direction A in (with support plate 4 removed), image 3 yes figure 1 View from direction B in (remove shaft assembly 3), Figure 4 yes figure 2 The C-C section diagram, Figure 5 yes figure 2 The D-D profile, Figure 6 yes figure 2 The E-E profile. exist Figure 1 to Figure 6 Among them, the back support device for a large-diameter reflector in the form of a spherical joint bearing of the present invention includes a large-diameter reflector 1, a lens back plate 2 for installing the large-diameter reflector 1, a lens for installing the large-diameter reflector 1, and a lens The shaft assembly 3 of the backplane 2, the adjustment connection assembly 5, the adjustment rod assembly 9, the screw drive 7, the clamping block 6 for installing the screw drive 7, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com