Method for evaluation of inflammable liquid explosion risk under unrestricted condition in outfield

An unconstrained and dangerous technology, applied in the direction of fuel oil testing, material inspection products, etc., can solve the problems of personal casualty, property, lack of test basis and loss of flammable liquid explosion hazards, and achieve the effect of avoiding high temperature interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

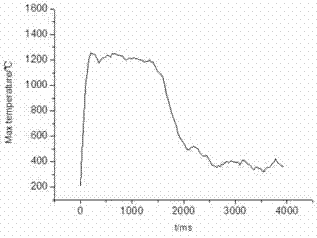

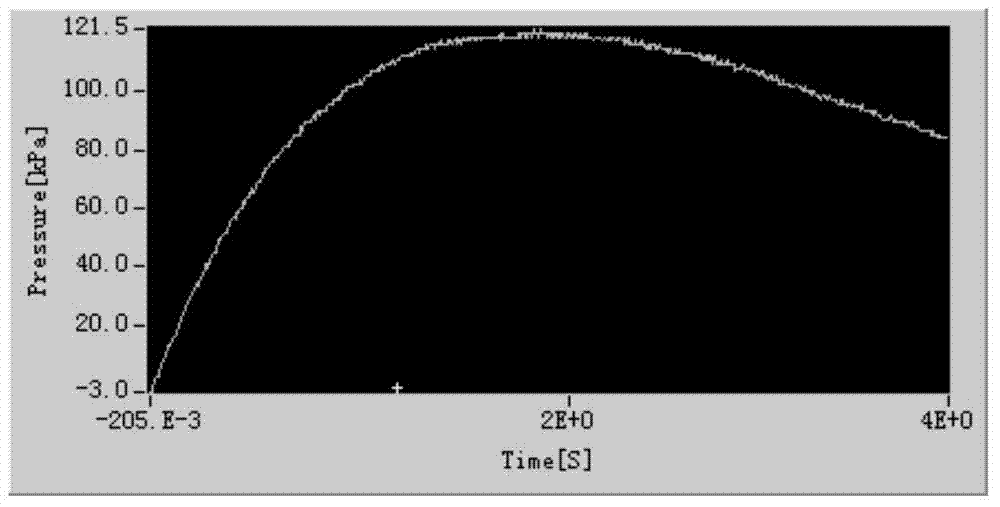

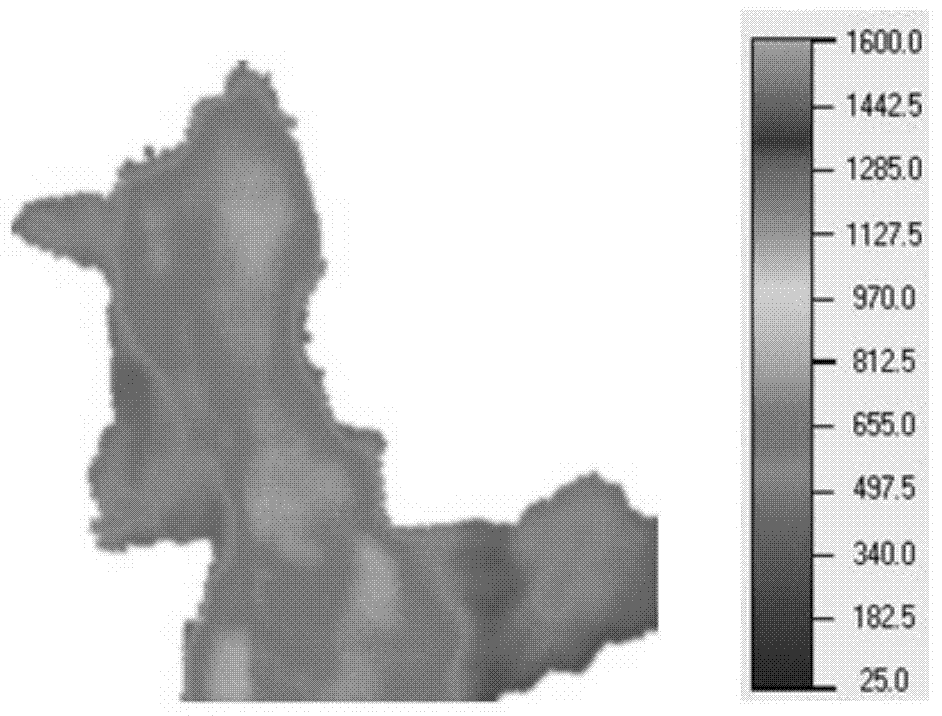

[0060] A method for judging the explosion hazard of flammable liquids under unrestrained conditions in an external field, comprising the following steps:

[0061] (1) Select the test site and meteorological conditions: The test site is selected to be carried out in the test range built according to the national standard, which is a concrete floor. The meteorological conditions during the test are all in line with the requirements of GJB3197-98, and the temperature wave during the test is within ±2°C.

[0062] (2) Pour the flammable liquid sample into the simulated container: pour -10 diesel oil into the simulated container with a volume of 5L, the material of the simulated container is galvanized iron sheet; the void rate is 40%, seal the simulated container, and let it stand More than 12 hours.

[0063] (3) Determine the position of the simulated container and the position of the measurement system: fix the simulated container on a steel frame with a height of 80 cm. Set the...

Embodiment 2

[0071] A method for judging the explosion hazard of flammable liquids under unrestrained conditions in an external field, comprising the following steps:

[0072] (1) Select the test site and meteorological conditions: the test site is selected to be carried out in the test range built according to the national standard, which is a concrete floor. The meteorological conditions during the test are in line with the requirements of GJB3197-98, and the temperature fluctuation range is ≤ ± 10 ℃.

[0073] (2) Pour the flammable liquid sample into the simulated container: pour the diesel oil into the simulated container with a volume of 1 L, the material of the simulated container is aluminum alloy; the void rate is 20%, seal the simulated container, and let it stand for more than 12 hours.

[0074] (3) Determine the position of the simulated container and the position of the measurement system: fix the simulated container on a steel frame with a height of 10 cm. Set the point on the...

Embodiment 3

[0079] A method for judging the explosion hazard of flammable liquids under unrestrained conditions in an external field, comprising the following steps:

[0080] (1) Select the test site and meteorological conditions: the test site is selected to be carried out in the test range built according to the national standard, which is a concrete floor. The meteorological conditions during the test are in line with the requirements of GJB3197-98, and the temperature fluctuation range is ≤±5°C.

[0081] (2) Fill the flammable liquid sample into the simulated container: pour kerosene into the simulated container with a volume of 1000L, the material of the simulated container is aluminum alloy; the void rate is 80%, seal the simulated container, and let it stand for more than 12 hours.

[0082] (3) Determine the position of the simulated container and the position of the measurement system: fix the simulated container on a steel frame with a height of 10 cm. Set the point on the ground...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com