Gas turbine combustor axial two-stage swirl nozzle with opposite directions

A technology with axial swirling and opposite directions, applied in the direction of combustion chamber, combustion method, continuous combustion chamber, etc., can solve the problems of poor mixing effect of fuel and air, pollutants affecting combustion tissue, and small airflow deflection angle, etc. Achieve the effects of improving combustion stability, improving combustion reliability, and reasonable velocity distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

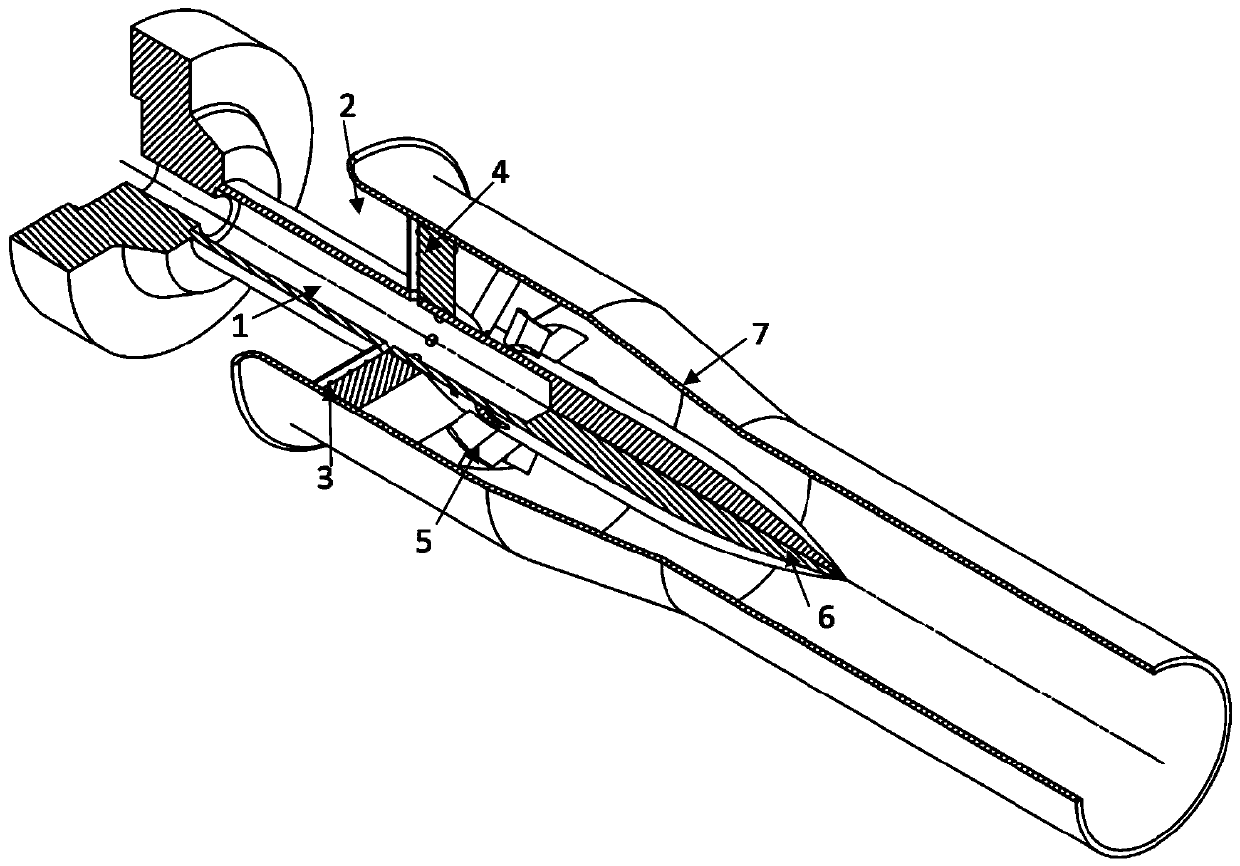

[0019] The principle, structure and specific implementation of the present invention will be further described below in conjunction with the accompanying drawings.

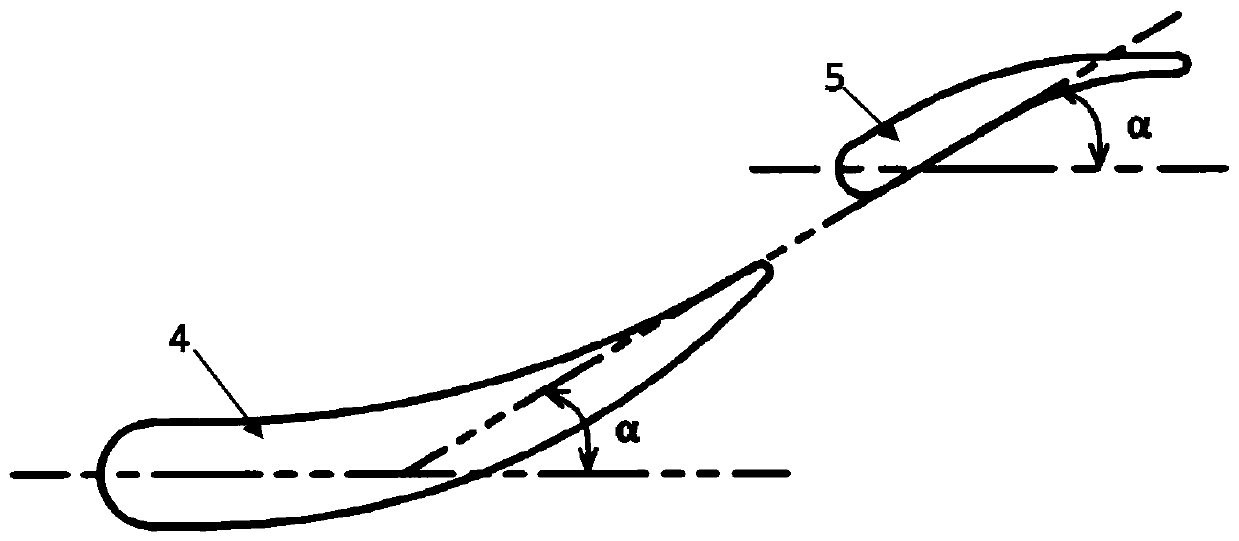

[0020] figure 1 Schematic diagram of the structural principle of the gas turbine combustor axial two-stage direction opposite swirl nozzle provided by the present invention, the nozzle includes a central fuel channel 1, and a peripheral annular air channel 2 and a central cone arranged coaxially with the central fuel channel 6. On the central cone 6 in the peripheral annular air channel 2, two swirl devices with opposite swirl directions are arranged in sequence in the axial direction; the first-stage axial swirl device 4 is located at the front end of the peripheral annular air channel 2, the The axial swirl device adopts hollow blades and communicates with the central fuel passage, and fuel injection holes 3 are opened on both sides of the hollow blades; the air inlet of the second-stage axial swirl device 5 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com