New electric water pump

An electric water pump, a new type of technology, applied in the pump, pump control, pump device and other directions, can solve the problems of insufficient pump lift, wrong rotation direction, insufficient water output, etc., to improve the use efficiency and reliability, reliable and simple to use, The effect of reducing the failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

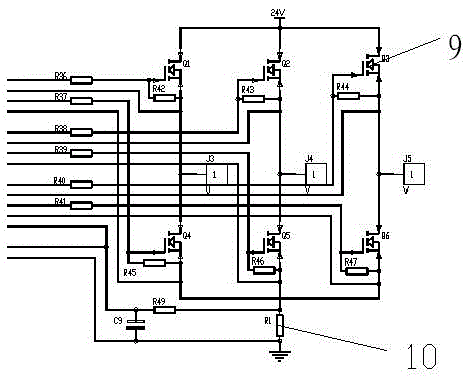

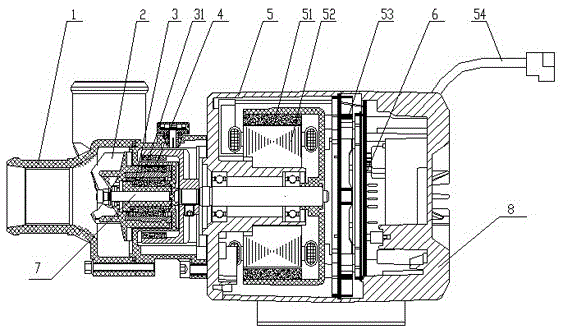

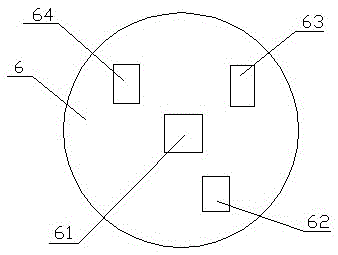

[0020] Embodiment: It includes a motor 5 and a water pump, the motor 5 is fixedly connected to the water pump, the motor includes a driving part and a control part, the control part includes a fixed shell 8, and a chip is arranged inside the fixed shell 8 Board 6, the chip board 6 is fixedly connected with the fixed shell 8, the chip board 6 is provided with an integrated chip 61, the integrated chip 61 is fixedly connected with the chip board 6, and the driving part includes a brushless The stator 52 and the brushless rotor 51, the brushless stator 52 is sleeved on the outside of the brushless rotor 51, and the chip board 6 is provided with an anhydrous overload protector 62, an anti-reverse connection protector 63 and automatic speed regulation device 64, the described anhydrous overload protector 62, anti-reverse connection protector 63 and automatic governor 64 are all fixedly connected with the chip board 6, and the described anhydrous overload protector 62 includes severa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com