Turnout for coal mine rope-drawn rail-trapped vehicles

A technology of rope traction and rail car, which is applied in the field of coal mine rope traction and rail car turnout, which can solve the problems of mine car falling off the road, easy to slip, and no reliable fastening method for the splicing section, etc., to achieve safe operation, smooth movement, joint tight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

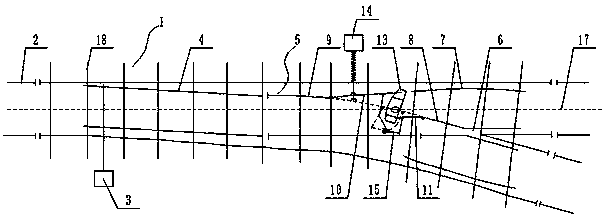

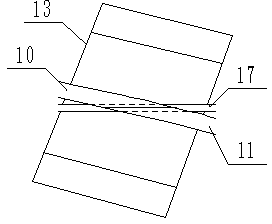

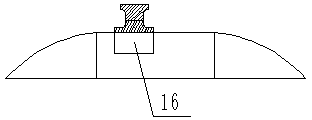

[0015] Such as figure 1 , Figure 4 As shown, the coal mine rope traction track turnout includes: single-opening turnout body 1, which is mainly composed of basic rail 2, point switch 3, point rail 4, guide curve rail 5, frog center 6, guard Rail 7 and wing rail 8, in which the basic rail 2, point switch 3, switch rail 4, guide curve rail 5, frog center 6, guard rail 7 and wing rail 8 are installed and arranged with the existing single-opening switch The structure is the same. The guide curve 5 is mainly composed of three parts including a fixed section 9, a front curved rail 10 and a rear curved rail 11. The fixed section 9 is fixed on the sleeper, and one end of the front curved rail 10 is hinged on the fixed section 9. , to ensure that the forward curved rail 10 can rotate around the fixed section 9, and the hinge point is installed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com