Trapezoidal sleeper

A sleeper and trapezoidal technology, applied in the field of new sleepers and elastic vibration-damping track systems, can solve problems such as unfavorable rail distribution, time-consuming and labor-intensive railway maintenance work, etc., so as to reduce maintenance workload, reduce maintenance workload, and reduce foundation vibration. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

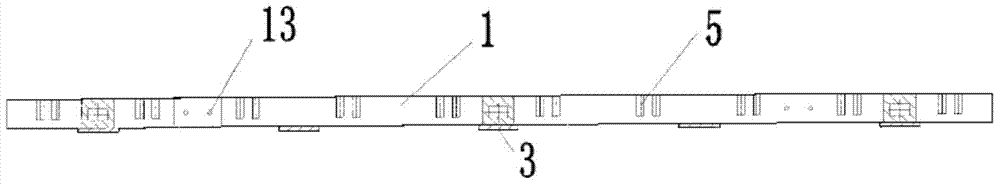

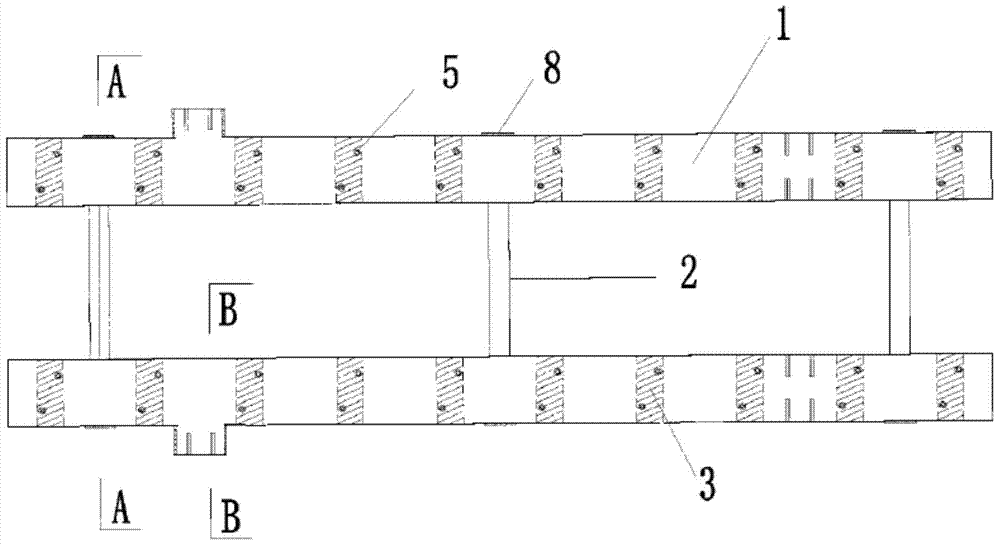

[0039] First, refer to Figure 1 to Figure 5 The longitudinal sleeper of the present invention will be described.

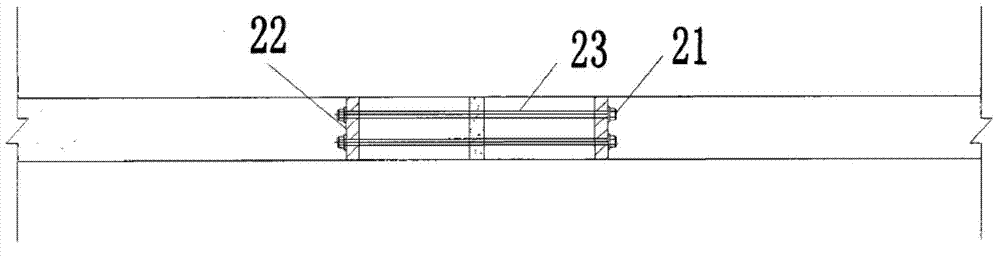

[0040] A longitudinal beam sleeper system of the present invention comprises a longitudinal beam sleeper and an elastic damping track system; as figure 1 and figure 2 As shown, the stringer type sleeper according to an embodiment of the present invention is formed by connecting stringer type sleeper units in series. The longitudinal beam sleeper unit includes a pair of longitudinal beams 1 respectively arranged under the rail 10 along the longitudinal direction of the rail. The longitudinal beams 1 are generally made of prestressed concrete. In order to improve the strength and rigidity of the longitudinal sleeper, multiple root pretensioned steel bars. However, the material of the longitudinal beam 1 is not limited thereto, and the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com