Bead embroidering device

A bead embroidery and bead guide technology, which is applied in the field of embroidery machinery, can solve the problems of complex positioning structure, inconvenient mass production, mechanical problems, etc., and achieve the effect of broad market prospect, convenient maintenance and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

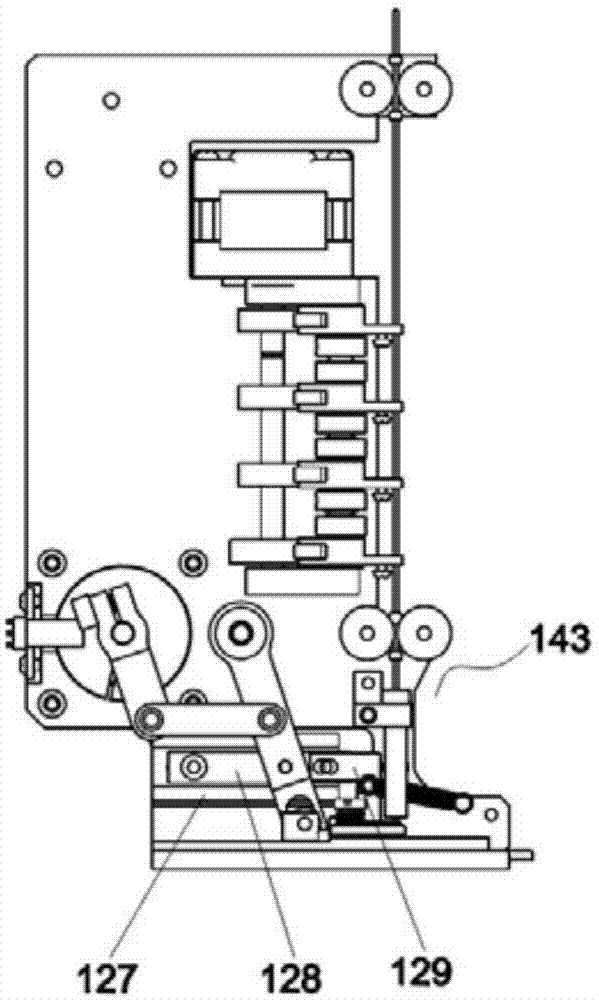

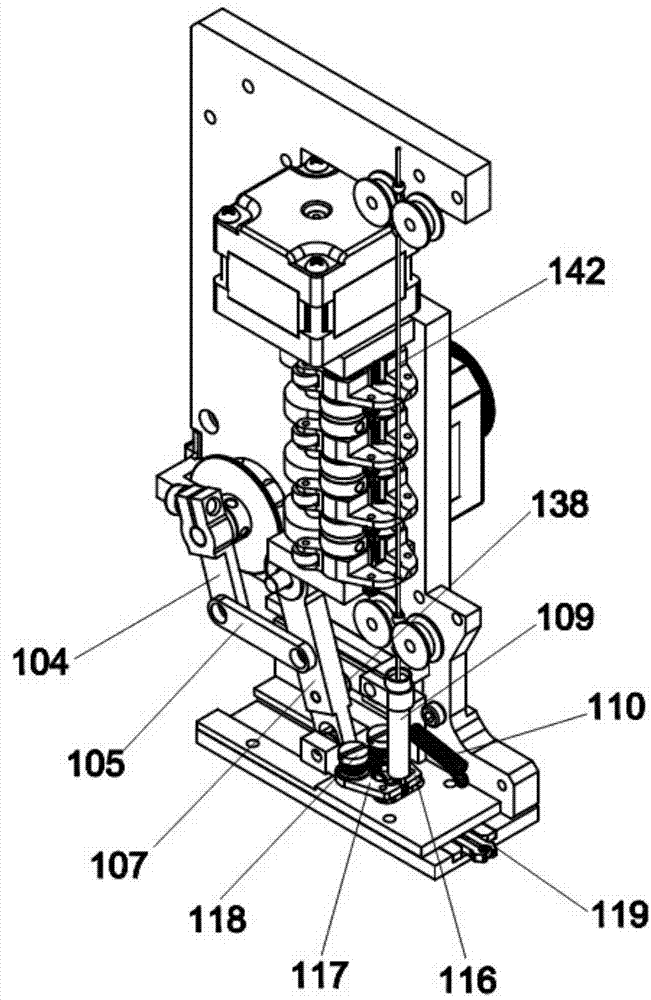

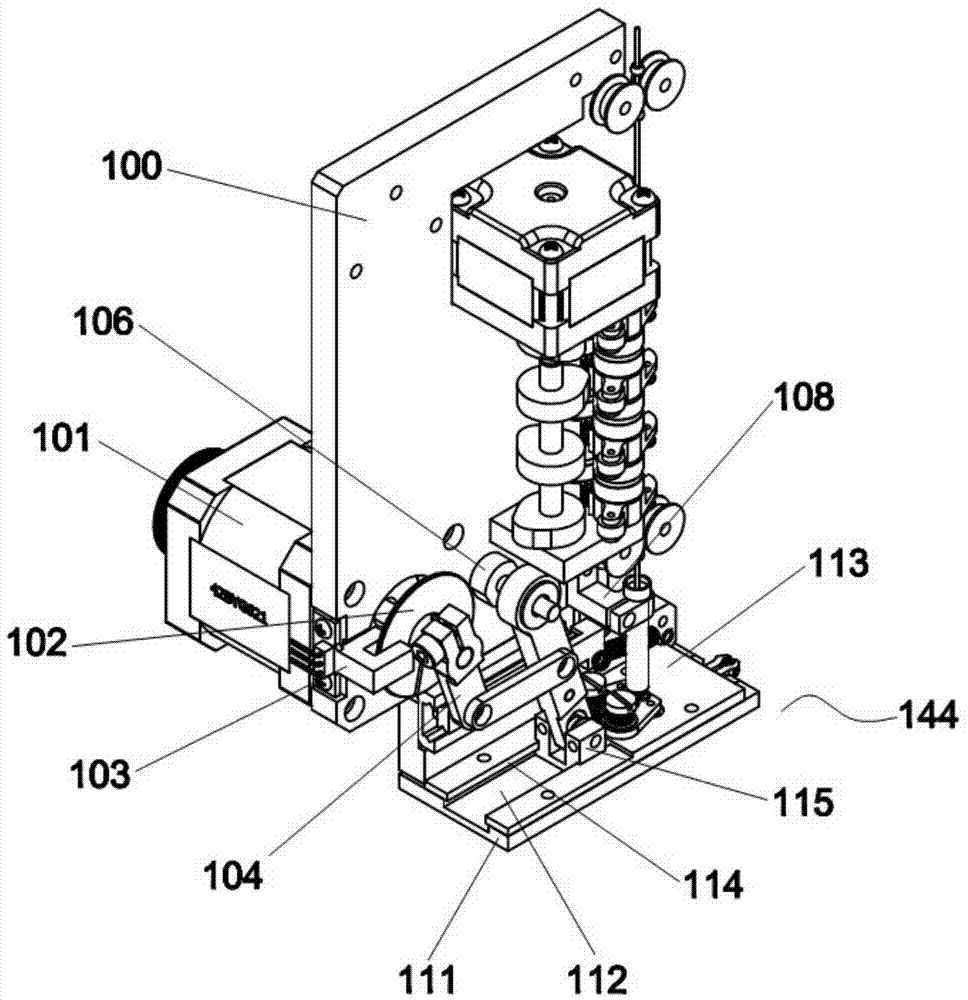

[0032] refer to Figure 1 to Figure 7 ,Such as Figure 1 to Figure 7 A bead embroidery device shown includes a bead guide rod 142, a feeding mechanism 143, a positioning clamping mechanism 132 and a feeding mechanism 144, and also includes a motor board 100 for supporting the whole device, and the motor board 100 is provided with Power drive device 101, described motor plate 100 side is provided with origin optocoupler 103; Wherein, also comprises the sliding fixing plate 111 that is fixed on the bottom of motor plate 100, described sliding fixing plate 111 is provided with sliding clamping plate 115, The sliding clamping plate 115 is provided with a jaw 119, the sliding fixing plate 111 is also provided with a cover plate 113, the cover plate 113 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com