Drawing machine for producing carbon fiber

A drafting machine and carbon fiber technology, applied in fiber processing, fiber chemical characteristics, textiles and papermaking, etc., can solve the problems of high life cost and economic cost, achieve high safety value and economic value, strong applicability, and reduce accidents The effect of the accident

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

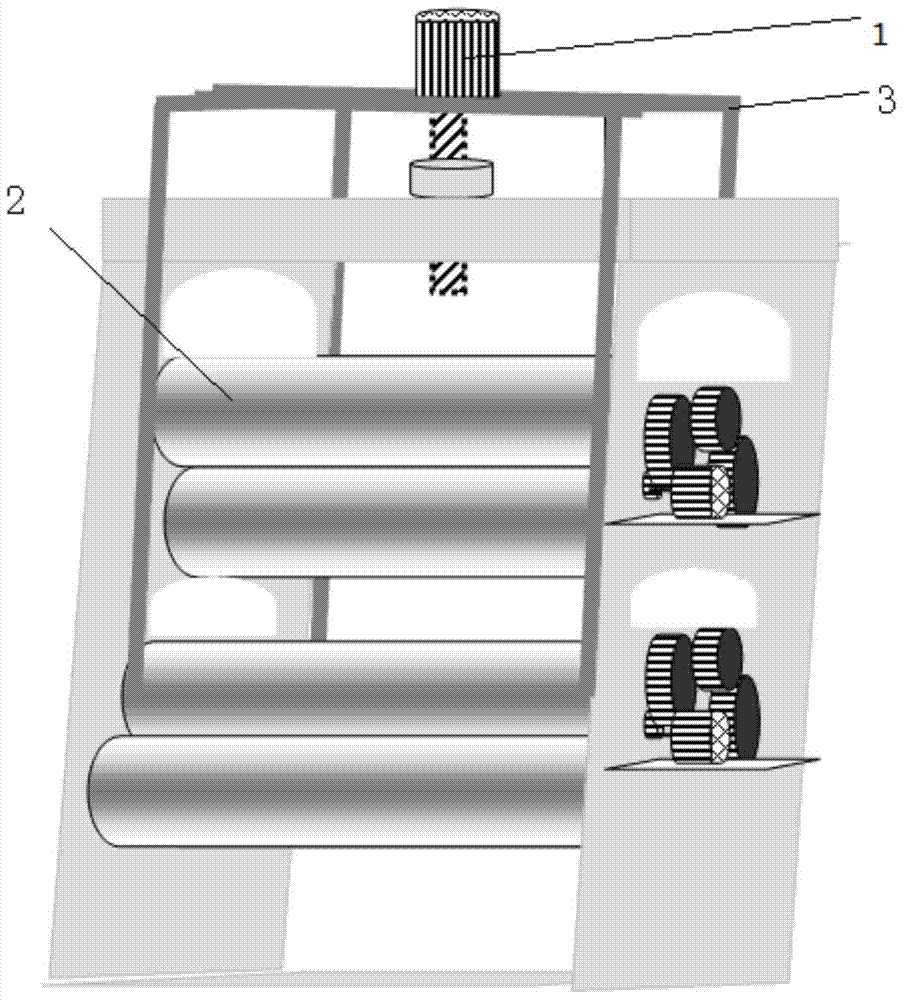

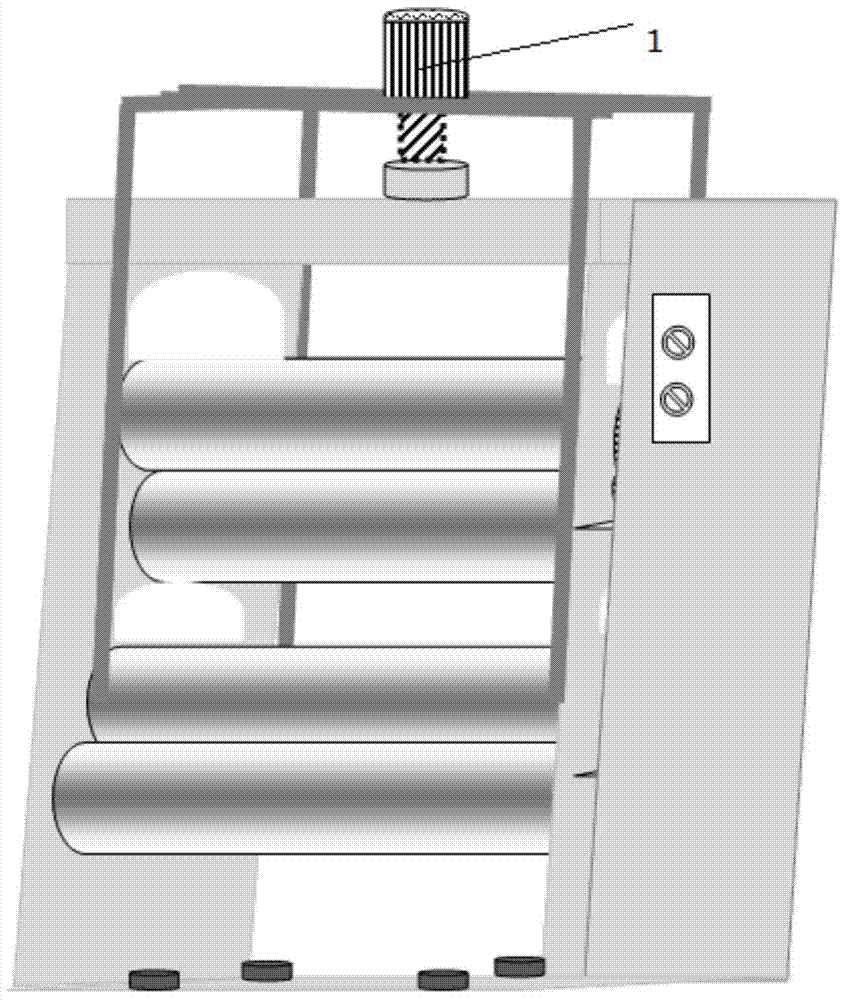

[0016] refer to Figure 1-2 As shown, the present invention provides a kind of drawing machine that is used to produce carbon fiber, comprises roller and frame 3, and described roller is divided into two layers, each layer has three rollers, and each layer of rollers includes transmission Roller 2 and auxiliary roller, hydraulic pressure or mechanical lifting device are installed on the transmission roller 2 of the upper layer roller, and limit mechanical switch 1 and automatic induction switch are installed on the frame 3 directly above the upper layer roller.

[0017] The limit mechanical switch 1 can limit the set height of the roller, and the automatic sensor switch is equipped with an infrared sensor function, which can sense whether there is a foreign object falling into the drafting machine through the infrared sensor.

[0018] Preferably, the surface of the rollers of the tractor of the present invention is coated with rubber or engineering plastics.

[0019] The rubb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com