A new type of trolley system

A trolley, a new type of technology, applied in the direction of load block, load suspension components, transportation and packaging, etc., can solve the problems of wheels, guide rails and girders wear, prone to safety hazards, low loading and unloading efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The following embodiments will be used to further illustrate the present invention in conjunction with the accompanying drawings.

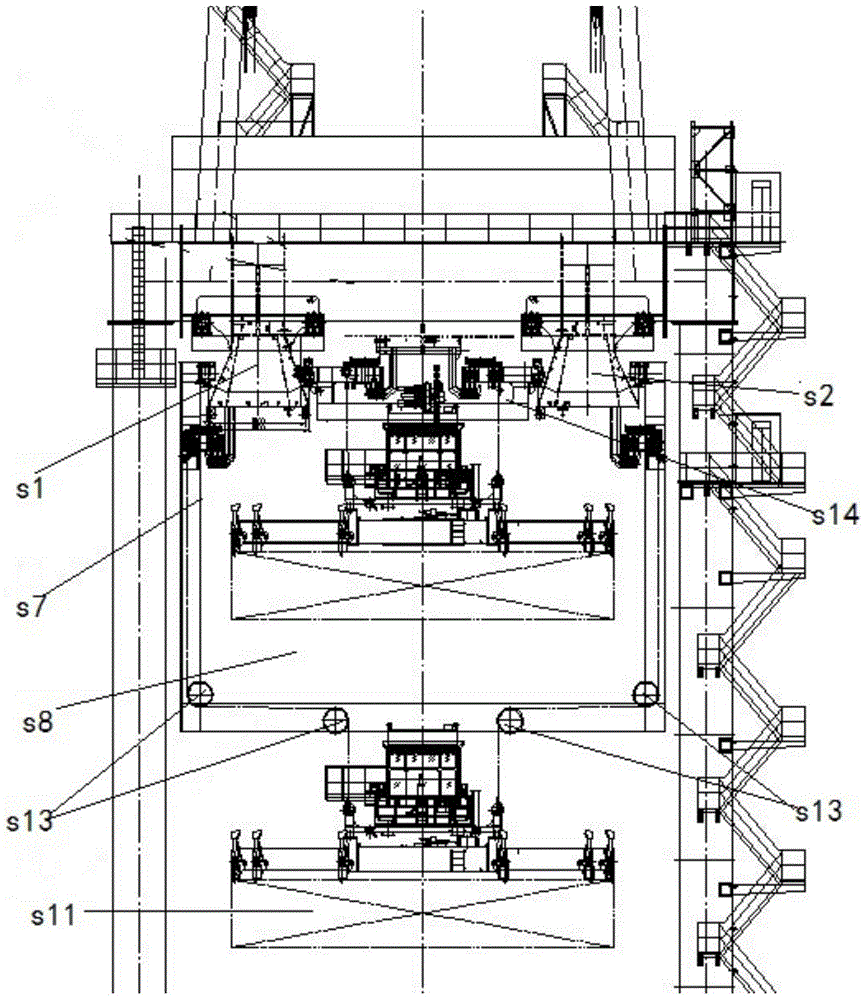

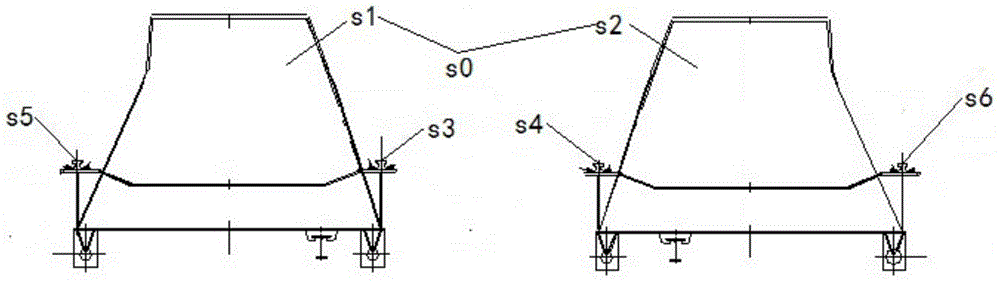

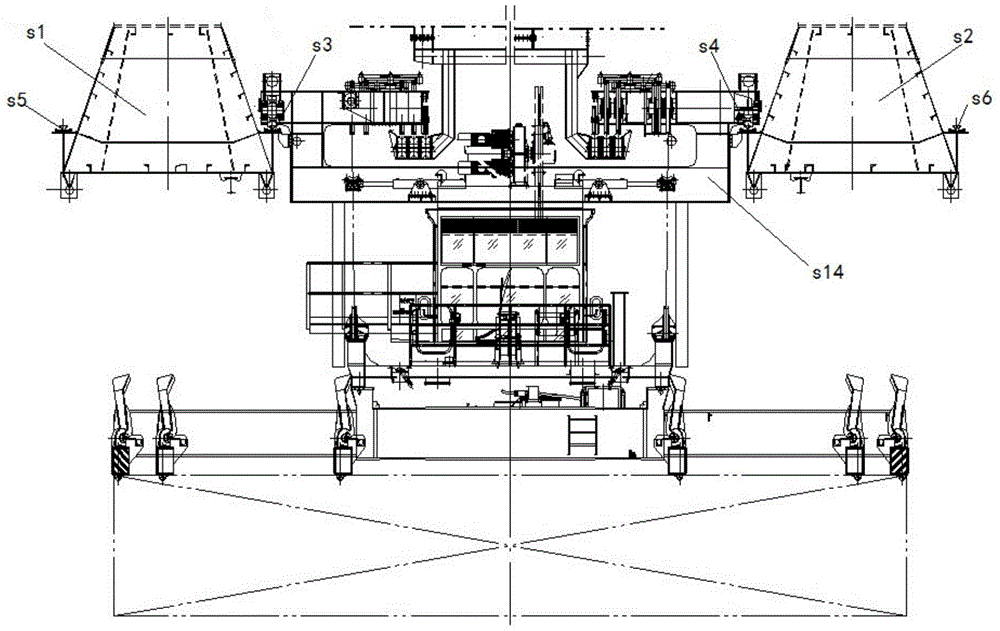

[0036] Such as Figure 1-Figure 4 As shown, a new type of trolley system described in this embodiment includes a first traveling mechanism s12 that can walk along the first guide rail s5 installed on the quay bridge girder s0, and can walk along the first guide rail s5 installed on the quay bridge girder s0. The second traveling mechanism s18 that runs on the two guide rails s6, the rigid vehicle frame s7 that rigidly connects the first traveling mechanism s12 and the second traveling mechanism s18, and the hanger connected below the rigid vehicle frame s7; The rigid frame s7 has a structural space s8 for the upper trolley s14 to pass through, and the lower trolley s15 satisfies the following condition: the stabilizing moment ΣMs caused by the gravity of the lower trolley s15 is greater than the horizontal inertia of the lower trolley s15 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com