A special tool for disassembly and assembly of wedge rings

A tooling and wedge ring technology, used in manufacturing tools, hand-held tools, etc., can solve the problems of high product scrap rate, difficulty in ensuring proper installation, and difficulty in ensuring the air tightness of cylinders, and achieves optimization of human resources and labor-saving mechanical structure. , pressure and uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described by examples below, but it should be noted that the purpose of announcing examples is to help further understand the present invention, but those skilled in the art can understand: without departing from the spirit and spirit of the present invention and the appended claims Various alternatives and modifications are possible within the scope. Therefore, the present invention should not be limited to the content disclosed in the examples, and the protection scope of the present invention is subject to the scope defined in the claims.

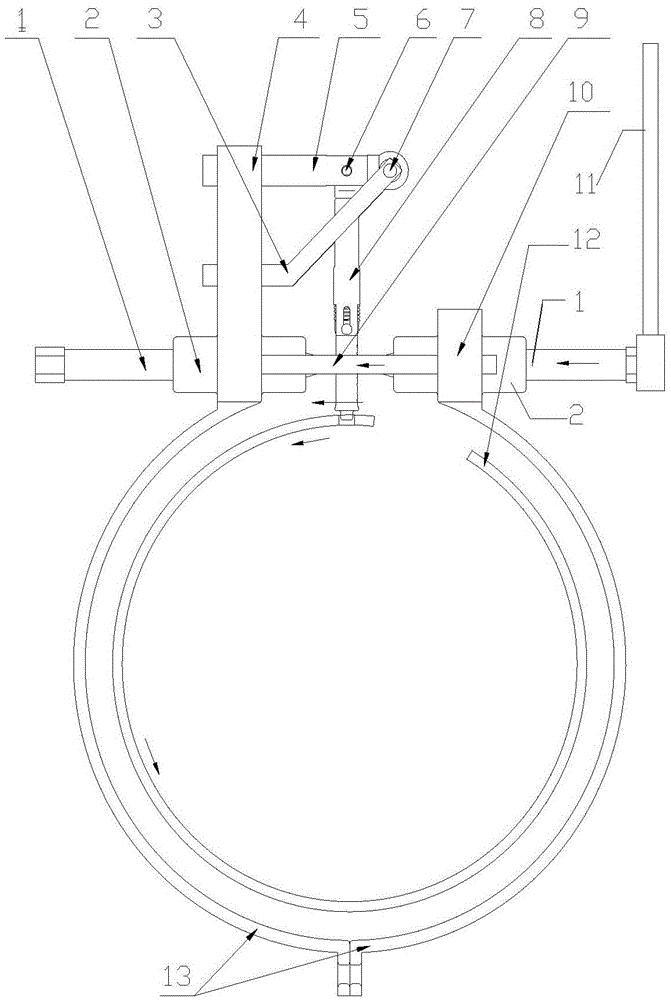

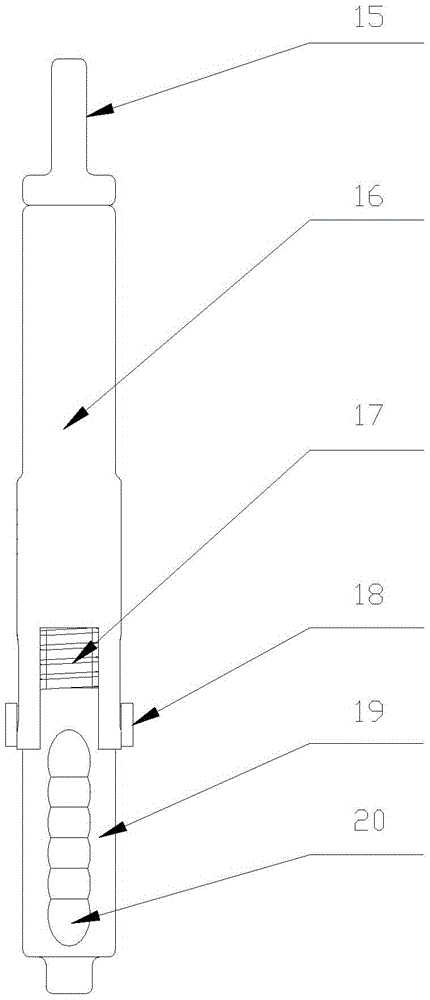

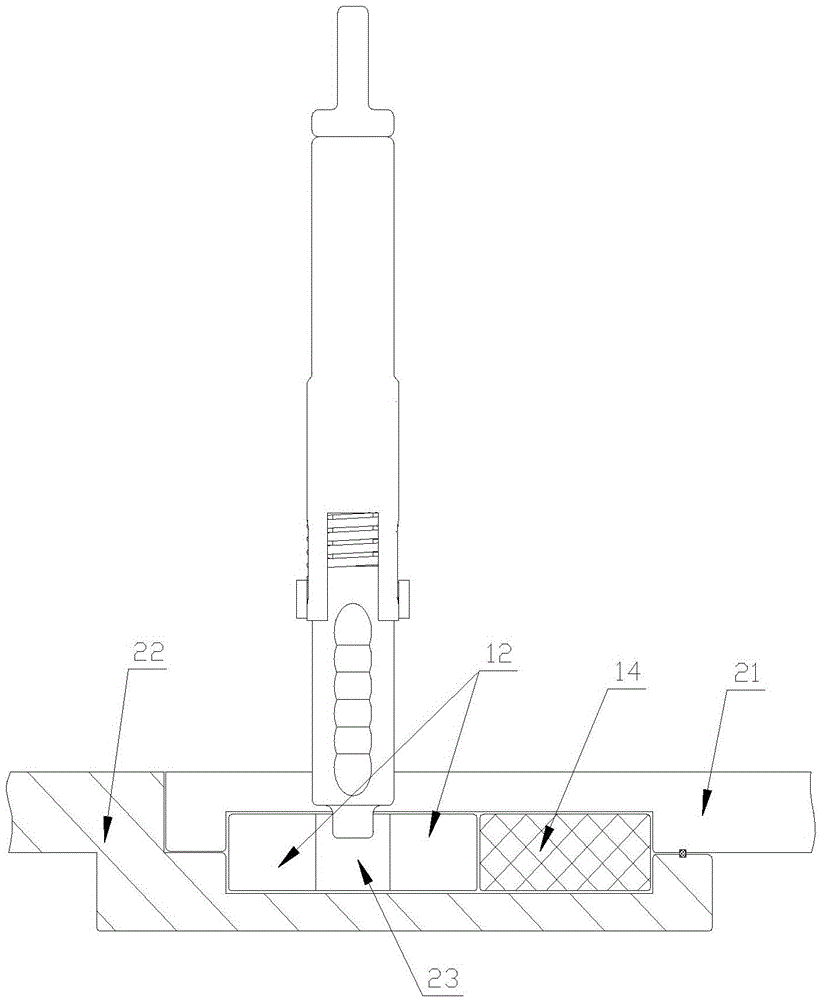

[0028] A special tooling for the disassembly and assembly of wedge rings, including a support structure, a telescopic pin assembly and a trapezoidal drive screw;

[0029] The support structure is composed of snap ring I13, snap ring II13, clip head I4, clip head II10, two double-ended connecting studs 9 and a support assembly.

[0030] Clamp head Ⅰ4 and clamp ring Ⅰ13 are welded into one body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com