A production rack for processing automobile clutch release bearings

A technology for separating bearings and clutches, applied in metal processing, bearing components, shafts and bearings, etc., can solve the problem of no rotation adjustment of the pressure plate, no consideration of bearing positioning, etc., to reduce the speed, save working time and labor, guarantee The effect of pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

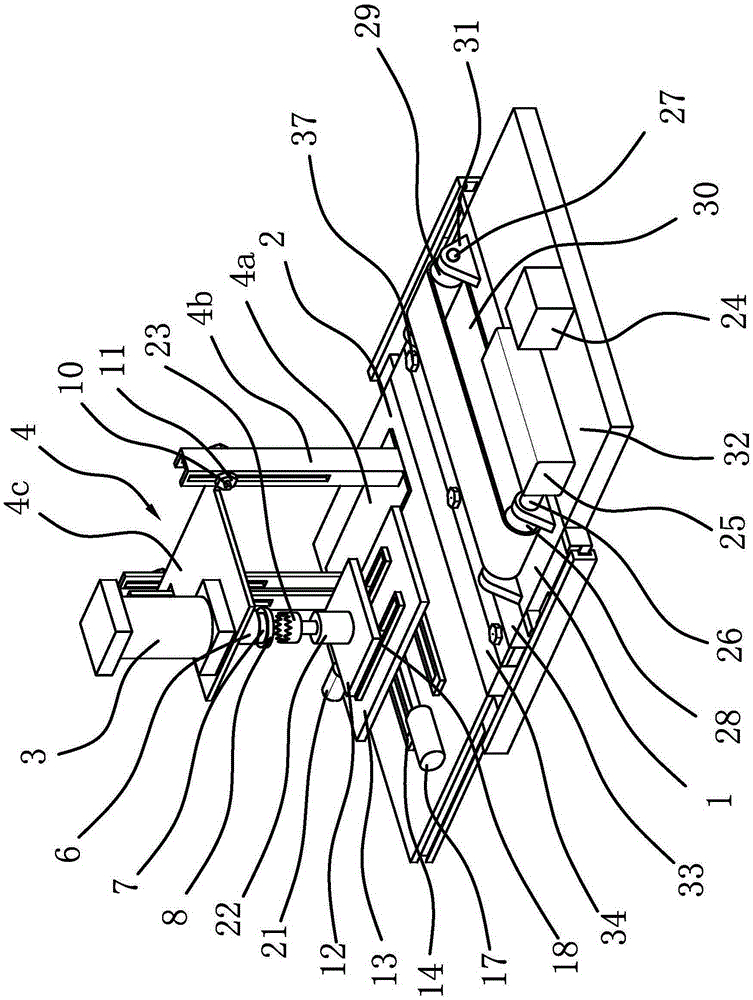

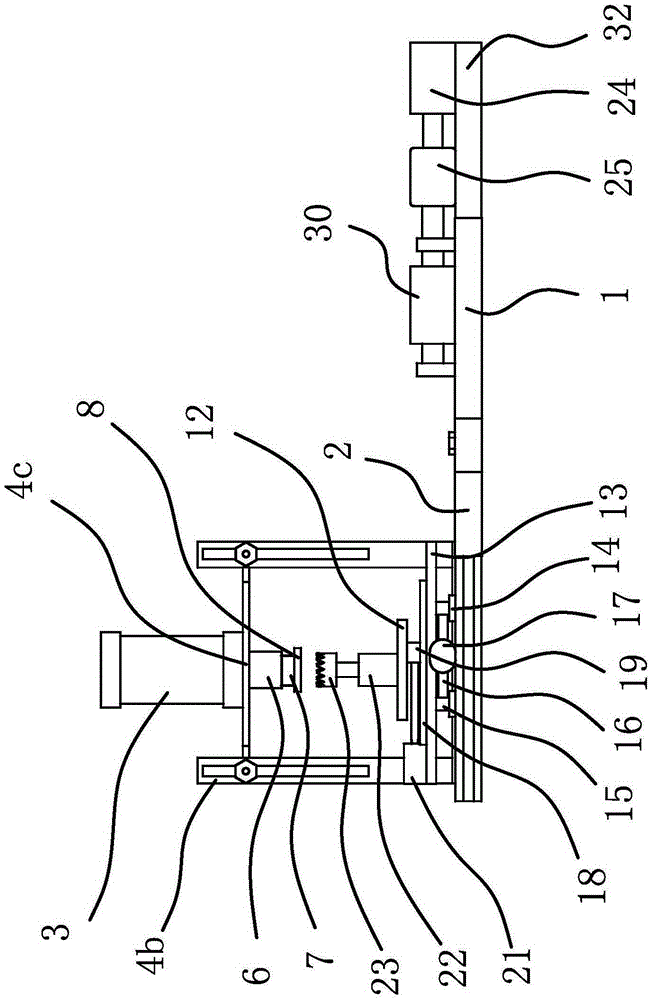

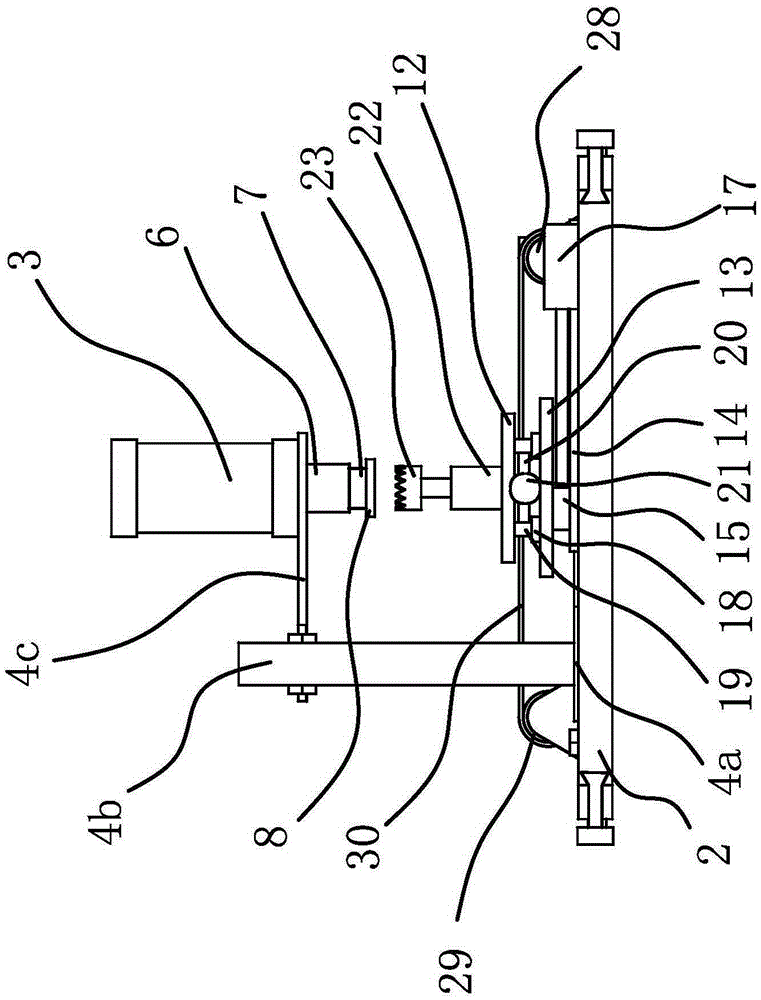

[0029] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0030] Such as Figure 1~4 As shown, a production rack for processing automobile clutch release bearings, wherein the release bearing includes a bearing inner ring, a bearing outer ring, a cage arranged between the bearing inner ring and the bearing outer ring, and a cage arranged in the cage Steel balls, this production frame includes a running water frame 1 and a working frame 2 arranged on one side of the running water frame 1 through a detachable structure. The running water frame 1 is provided with a transmission mechanism that can drive the separation bearing to move forward. The pneumatic press 3 capable of processing the release bearing is fixed on the work frame 2 through the installation device, and the work fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com