Processing method of short slot hole in pcb board

A processing method and PCB board technology, applied in metal processing and other directions, can solve the problems of inability to cover the guide hole, deformation of the short slot, and the inability of the drill to use force, so as to reduce the production cost, avoid the deformation of the short slot, and improve the finished product. Yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

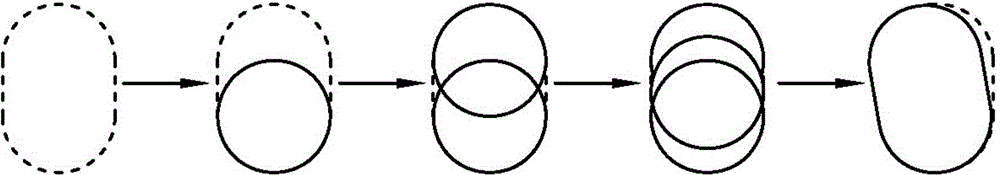

[0026] Depend on Figure 4 As can be seen, a kind of PCB board short slot hole processing method, it comprises the following steps:

[0027] ⑴ Drill two guide holes in the corresponding edges in the length direction of the short slot to be opened, the short diameter of the short slot is <1.0mm and the slot length / slot diameter is <2, and the diameter of the guide hole is ( The short diameter of the slot hole -0.1) / 2㎜~(the short diameter of the slot hole -0.25)㎜, the angle α between the center line of the two guide holes and the center line of the slot length direction in the counterclockwise direction is 10°~35°, so The distance between the guide hole and the edge of the short slot is 1㏕~3㏕;

[0028] The diameter of the guide hole in the present invention is preferably the short diameter of the slot hole / 2mm.

[0029] The distance between the guide hole and the edge of the short slot hole in the present invention is preferably 2㏕.

[0030] (2) Use a drill with a diameter eq...

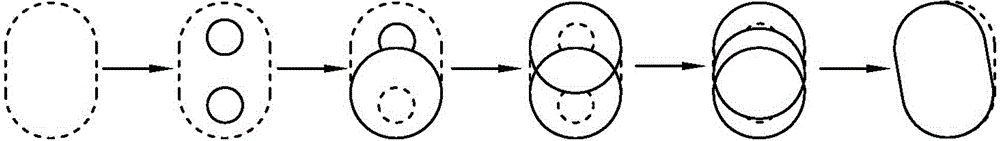

Embodiment 2

[0038] In the present invention, when the slot length / slot diameter is ≤1.3, the angle α is preferably 29°-35°.

[0039] In this embodiment, the short diameter of the slot hole is 0.6mm, the long diameter of the slot hole / short hole diameter is 1.3, and the diameter of the guide hole is preferably 0.3mm. The included angle α is 31°.

[0040] The rest are the same as embodiment 1.

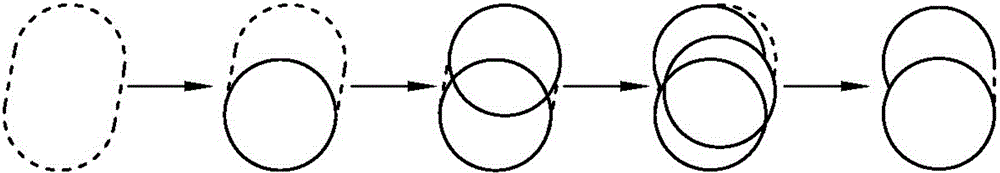

Embodiment 3

[0042] In the present invention, when 1.5

[0043] In this embodiment, the short diameter of the slot hole is 0.6mm, the long diameter of the slot hole / short hole short diameter is 1.8, the diameter of the guide hole is preferably 0.3mm, and the line connecting the centers of the two guide holes and the center line of the slot length in the counterclockwise direction The included angle α is 12°.

[0044] The rest are the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com