T beam mould moving device and use method thereof

A technology of shifting formwork and beam side formwork, applied in the direction of mold, bridge, bridge construction, etc., can solve the problems of large manpower and material cost, prolonged construction period, low overall efficiency, etc., to save manpower and material resources, and reduce the risk. , the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

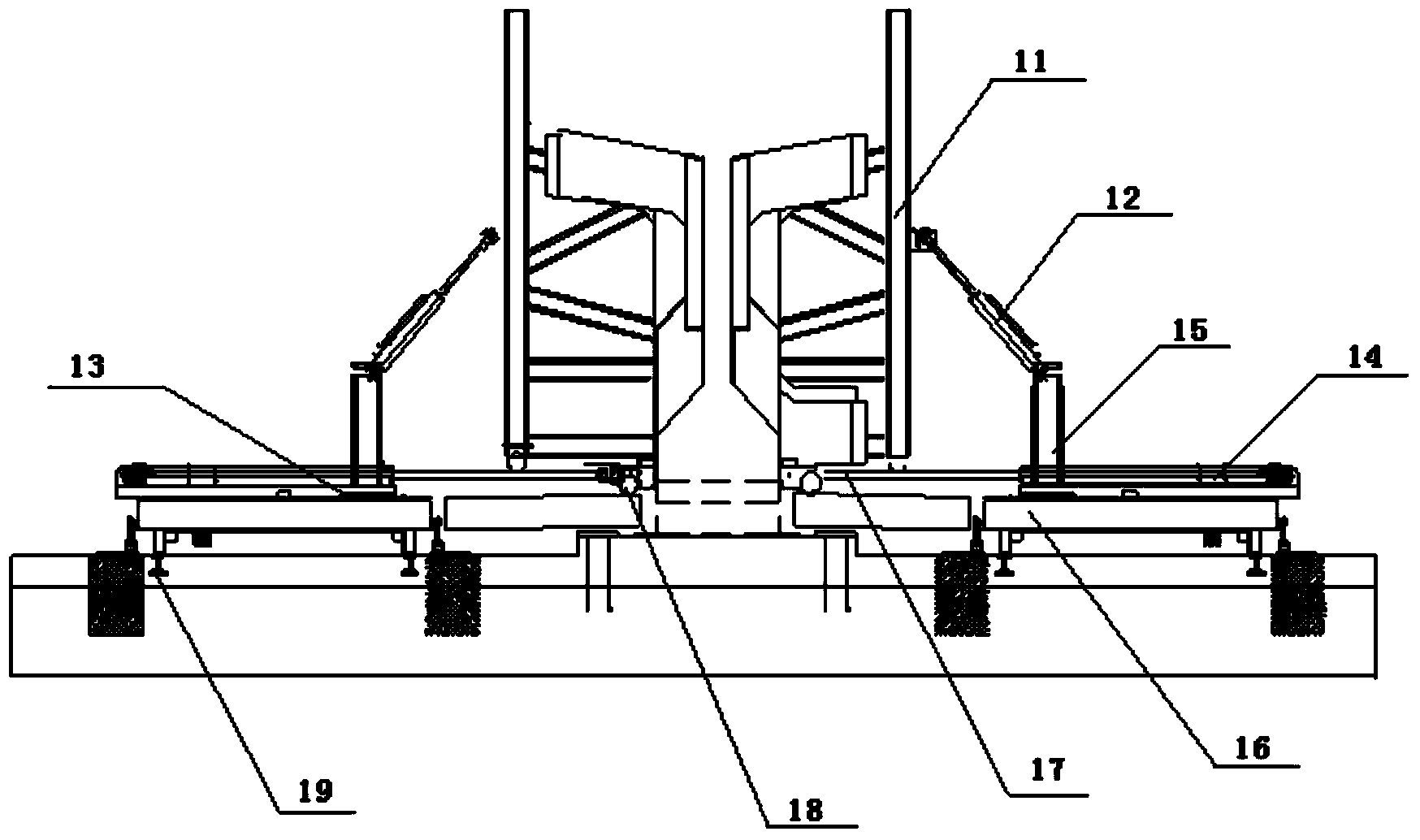

[0035] Such as figure 1 The schematic diagram of the structure of the T-beam mold-moving device of the present invention is shown, including a T-beam side mold 11, a cable-stayed cylinder 12, a slide rail 13, a flat-pull cylinder 14, a fixed end 15, a mold-moving trolley 16, an overlapping plate 17, and a pulley block 18, guide wheel 19, protrusion 20, groove 21, pin hole 22, slideway 23.

[0036] For a T-beam construction site, rails are respectively laid on both sides of the T-beam side form 11, and a mold-moving trolley 16 is set on the track, wherein the lower surface of the mold-moving trolley 16 is provided with a guide wheel 19, which is realized by the sliding action of the guide wheel 19. The movement of the mold shifting trolley 16 on the track, the traction power unit of the mold shifting trolley 16 can be a reel type electric flat car, a storage battery flat car and a gasoline engine flat car, wherein the preferred gasoline engine and battery drive combination form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com