Improved booster device for die casting machine

A pressurization device and die-casting machine technology, which is applied in the field of die-casting machines, can solve problems such as pressurized contact instability, and achieve the effects of timely pressurization, rapid pressure build-up, and stable pressurized contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to more clearly illustrate the design logic requirements of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments:

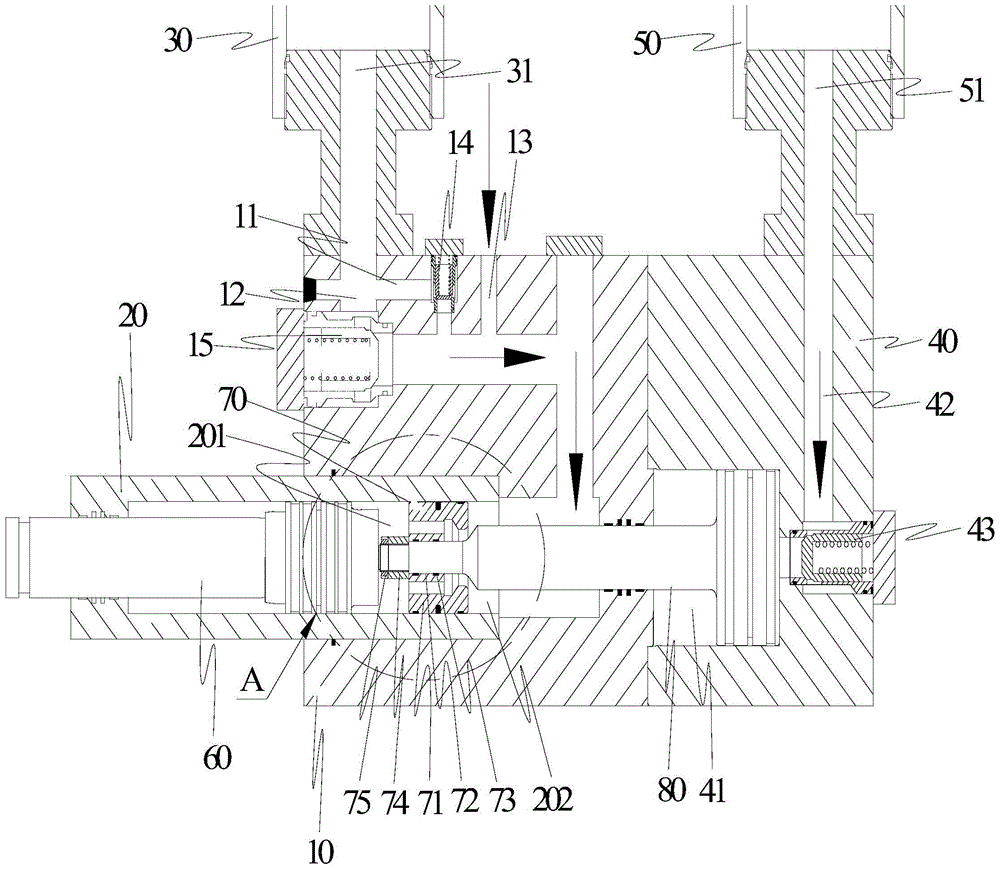

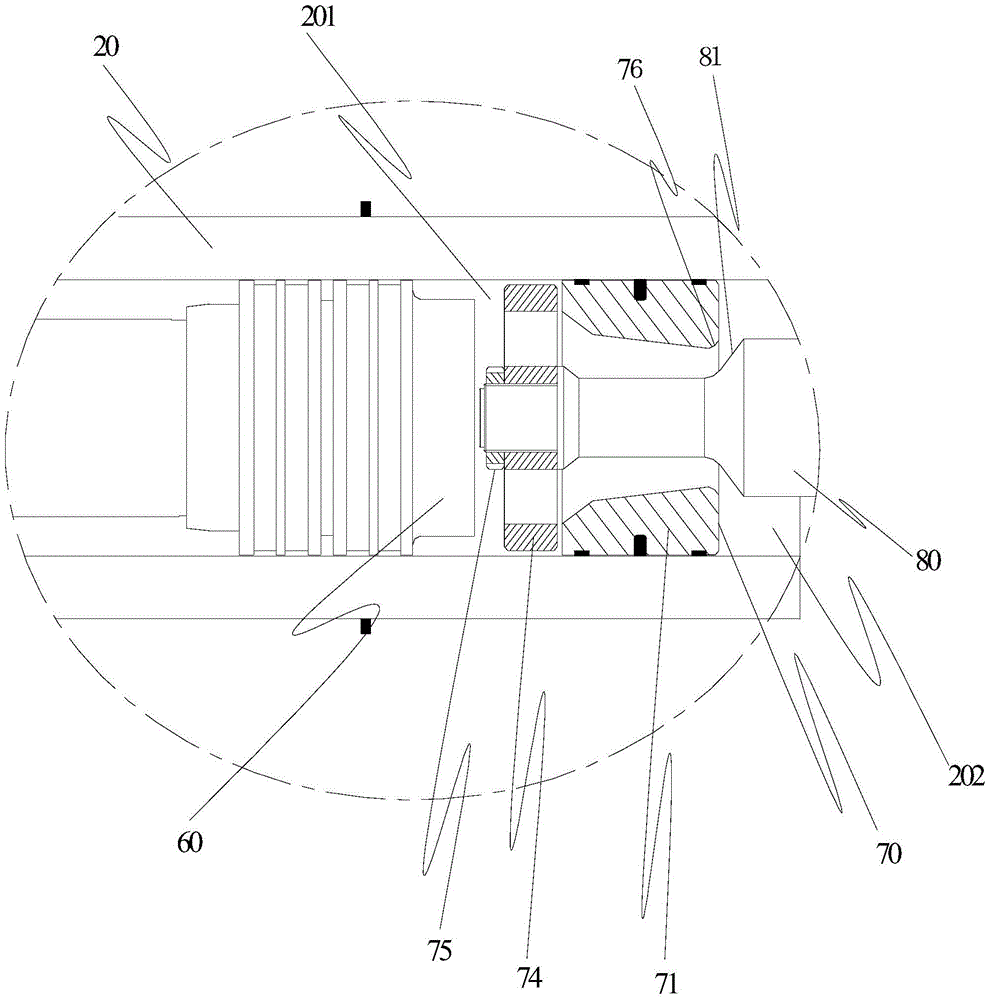

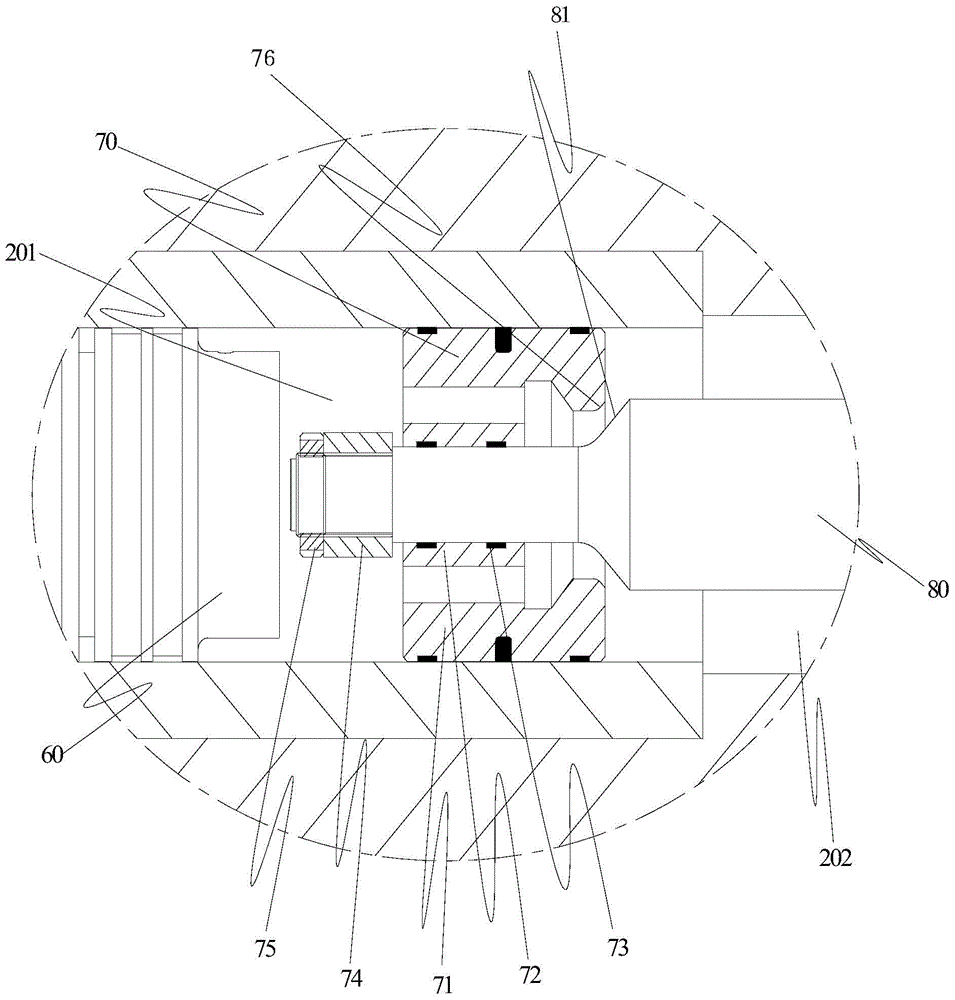

[0035] like figure 1 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 As shown, an improved booster device for a die casting machine includes a first base 10 , a beating cylinder 20 , a second-speed accumulator 30 , a second base 40 and a booster accumulator 50 .

[0036] Wherein, the first base 10 is provided with a first flow channel 11, a second flow channel 12 and a third flow channel 13, the first flow channel 11 is provided with a quick insert valve 14, and the second flow channel 12 is provided with Two quick insert valves 15, the third flow channel 13 is used to inject slow pressure oil.

[0037] The feeding cylinder 20 is installed on the first base 10, and the feeding cylinder 20 is provided with an axially movable feeding pis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com