A Plastic Constrained Member for Bending Thin-Walled Profiles

A technology of constraining components and plasticity, applied in the direction of forming tools, metal processing equipment, manufacturing tools, etc., can solve problems such as uneven deformation, inability to form hyperboloid bending, complex mandrel structure, etc., to ensure the quality of the curved surface, installation and use Simple process and wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

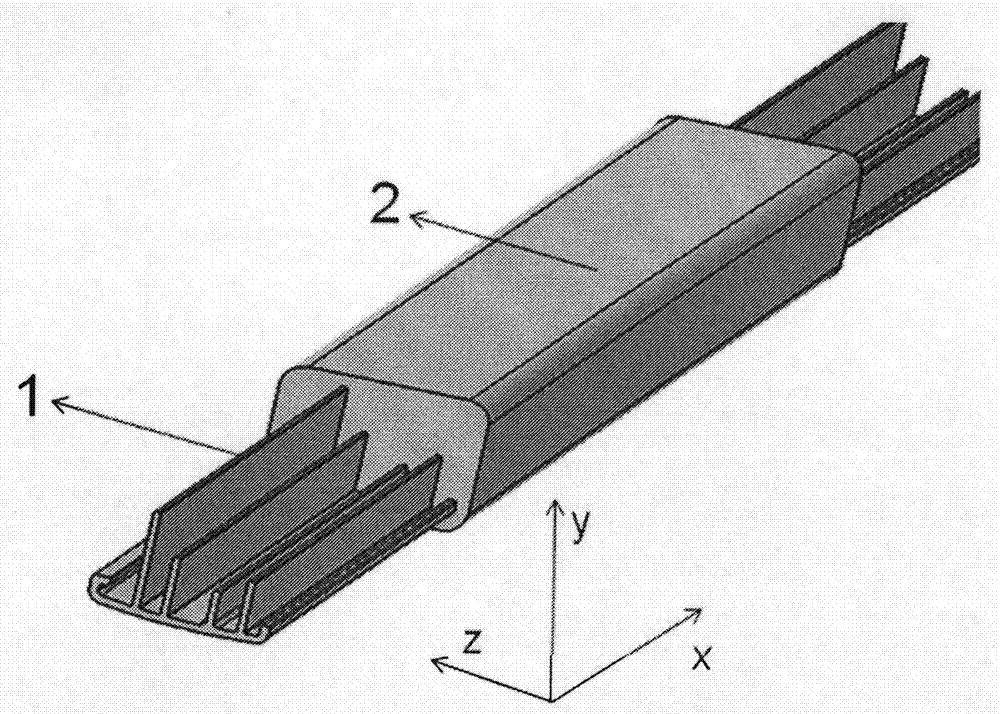

[0024] Such as figure 1 As shown, the thin-walled profile 1 with an open special-shaped cross-section cooperates with the flexible constraining member body 2 to ensure that the constraining member body 2 completely surrounds the thin-walled profile 1 with an open special-shaped cross-section. The thin-walled profile 1 with open special-shaped cross-section is a profile of metal materials such as aluminum alloy and stainless steel. If the thin-walled profile 1 lacks restraint during the bending process, the surface of the sharply bent part will be convex or concave, seriously affecting the quality of the product. For this reason, the body 2 of the flexible constraining member is designed to constrain the severe bending part of the thin-walled profile 1 to ensure the quality of the bent product. The body 2 of the flexible constraining member is made of plastic materials such as nylon 6 (PA6), cast nylon (MCPA) or polyurethane (PU), and has flexibility. Three-dimensional bendin...

Embodiment 2

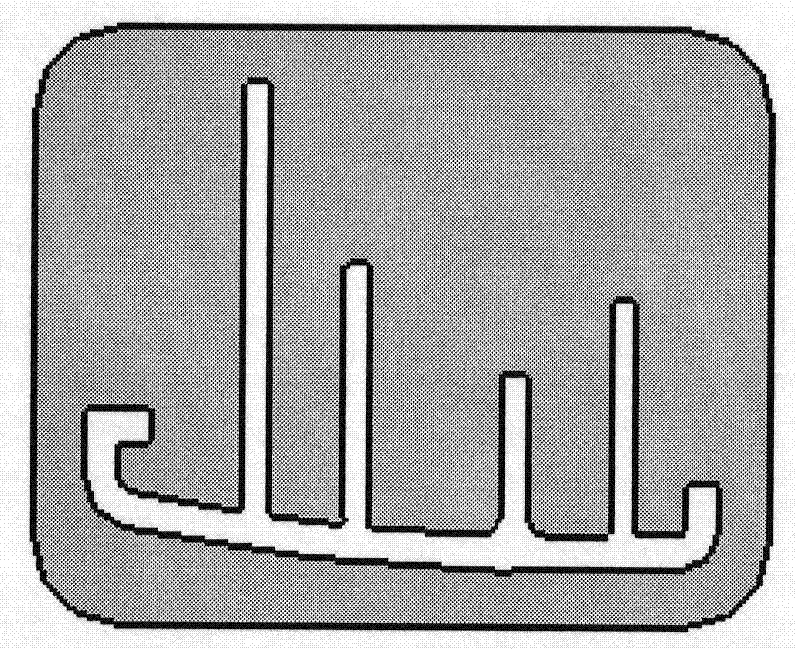

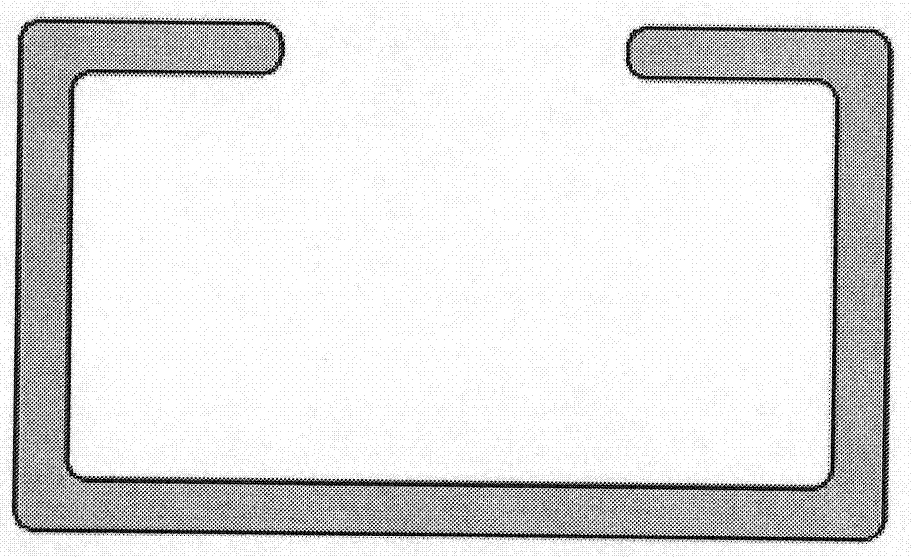

[0026] For such as image 3 The semi-closed "mouth" cross-section thin-walled section shown, adopts such as Figure 4 The flexible constraining member shown. The restraining member body 2' is made of plastic materials such as nylon 6 (PA6), cast nylon (MCPA) or polyurethane (PU). That is, three-dimensional bending is realized. The cross-sectional shape of the restraining member body 2' is also a "mouth" shape, which matches the cross-sectional shape of the thin-walled profile. In order to ensure that the constraining component body 2' is smoothly inserted into the thin-walled profile 1, the size of the constraining component body 2' can be designed to leave a slight gap between the constrained component body 2' and the thin-walled profile 1, for example less than 0.2 mm. During the bending forming process, the constraining member body 2' is inserted into the severe bending part of the thin-walled profile for stretch bending or press bending; after the forming is completed, ...

Embodiment 3

[0030] for Image 6 The semi-closed thin-walled profile with a semi-circular cross-section shown has a semi-circular cross-sectional shape of the constraining member body, which is also made of plastic materials such as nylon 6 (PA6), cast nylon (MCPA) or polyurethane (PU). There is a slight gap between the section size and the thin-walled profile, for example, less than 0.2 mm. The body of the constraining member can be used with a metal spacer with a drawing groove as required.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com