Compressing mechanism for high-efficiency air filter

A compacting mechanism, high-efficiency air technology, applied in the fields of dispersed particle filtration, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of reduced filter service life, uneven filter force, and reduced elasticity of sealing strips. , to achieve the effect of prolonging the service life, pressing and loosening the operation is simple and fast, and the pressing force is evenly distributed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

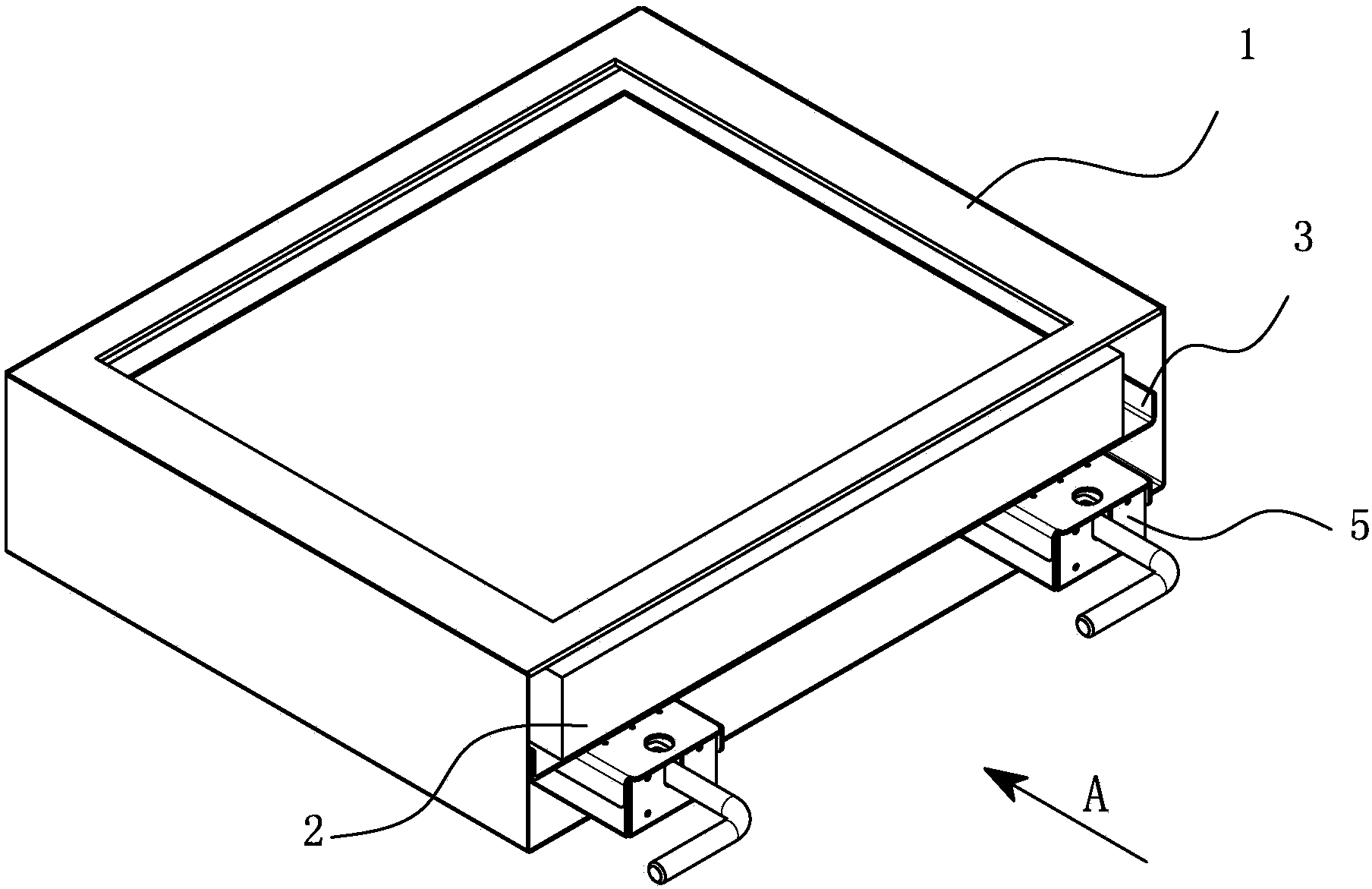

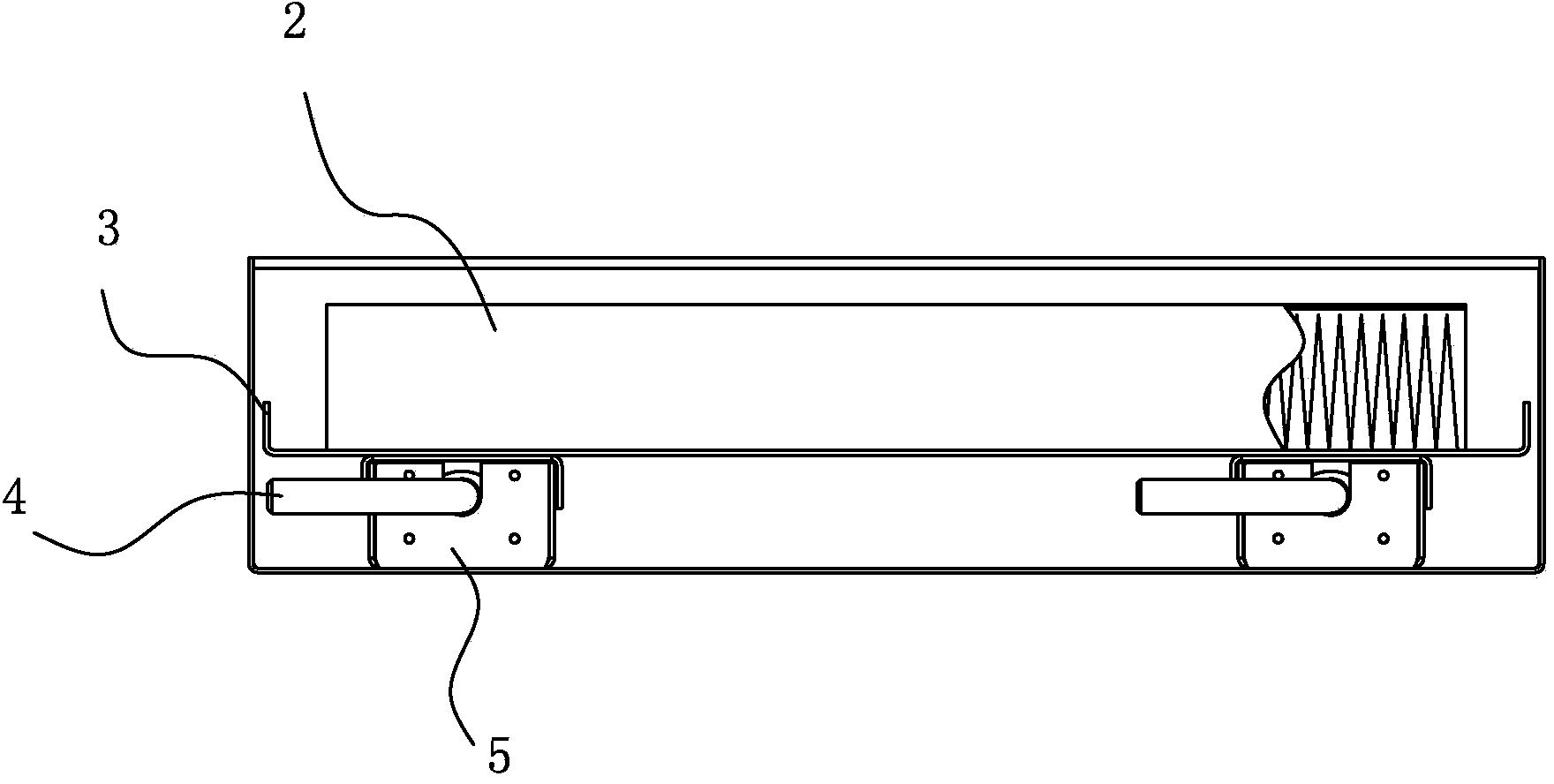

[0031] Embodiment one: see Figure 1~6 As shown, a high-efficiency air filter compression mechanism includes a box body 1 and a compression device arranged in the box body 1. The compression device includes two pre-tightening structures 5 and a pressure frame 3 carrying the filter 2. And four spring members 6 respectively located under the four corners of the pressure frame 3, the pre-tensioning structure 5 is located under the pressure frame 3, including a driving part and a pushing part connected with the driving part, and the pushing part is against the On the pressure frame 3, the pushing part has a degree of freedom to push the pressure frame 3 to move through the driving part, and the distance of the degree of freedom is matched with the gap between the filter 2 and the top cover of the box body 1; The elastic member 6 is arranged between the bottom of the box body 1 and the pressure frame 3 , and the distance between its free height and compressed height is greater than...

Embodiment 2

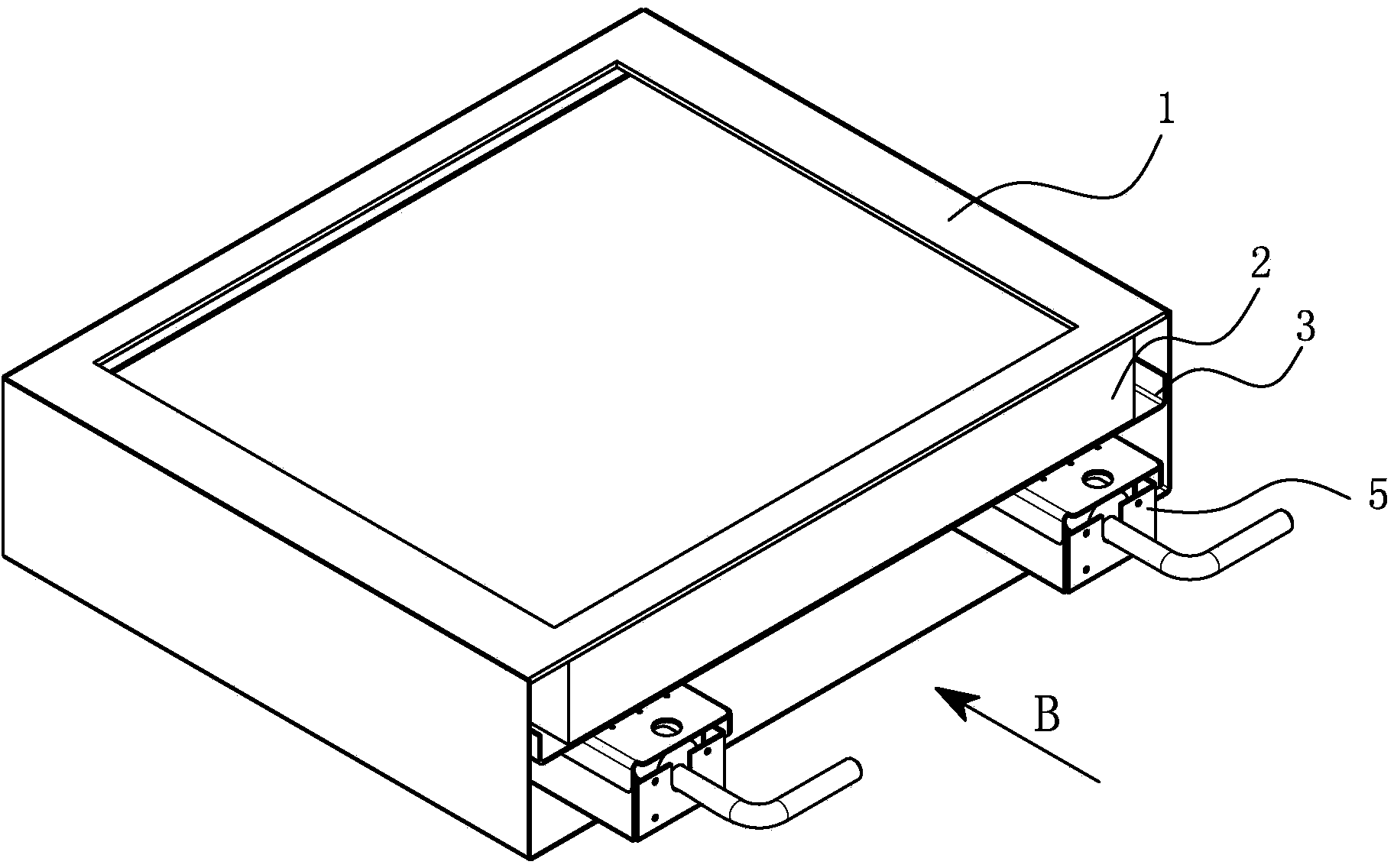

[0036] Embodiment two: see attached Figure 7-9 As shown, a high-efficiency air filter compression mechanism includes a box body 1, a compression device arranged in the box body 1, and the compression device includes a pre-tightening structure, a pressure frame 3 carrying a filter 2, and respectively Four spring members 6 located under the four corners of the pressure frame 3, the pre-tensioning structure is located under the pressure frame 3, including a driving part and a pushing part connected with the driving part, and the pushing part is against the pressure frame 3 Above, the pushing part has the degree of freedom to push the pressure frame 3 to move through the driving part, and the distance of the degree of freedom matches the gap between the filter 2 and the top cover of the box body 1; the elastic member 6 It is arranged between the bottom of the box body 1 and the pressure frame 3, and the distance between its free height and compressed height is greater than the fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com