Goods Shelf Support Member Installation Device And Goods Shelf Post

A technology for installing devices and supporting parts, which is applied in the direction of adjustable cabinets, household appliances, applications, etc., can solve problems such as shelf tilt, appearance deterioration, and stepless position setting of shelf supporting parts, so as to achieve strong shelf support structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

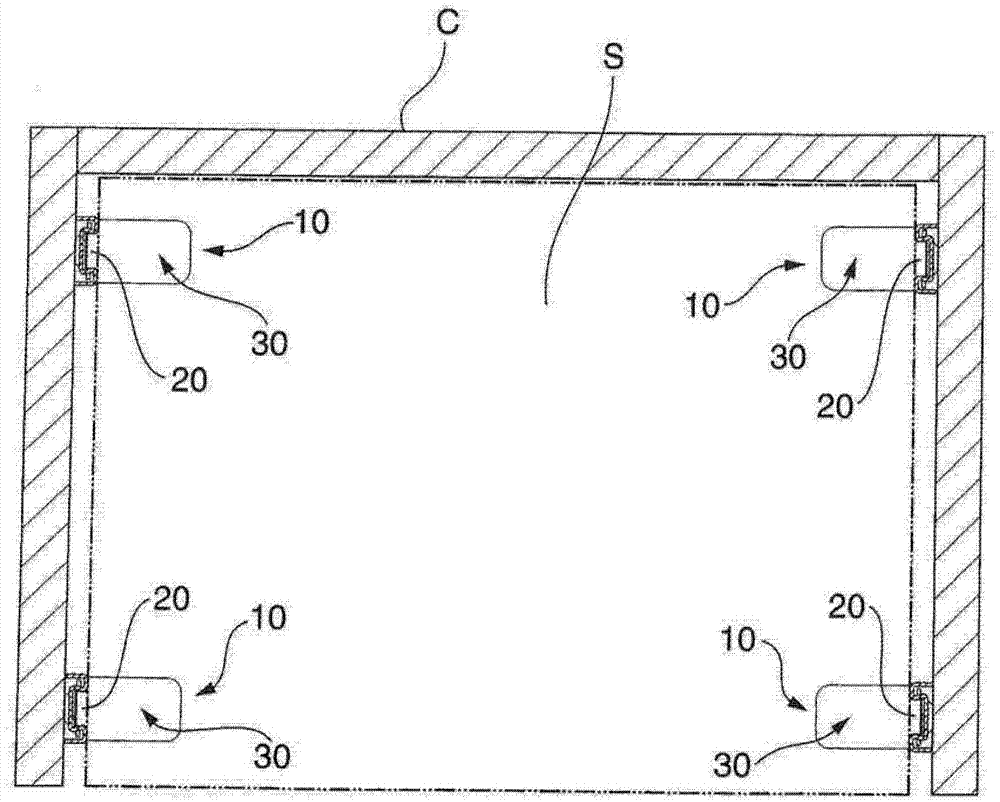

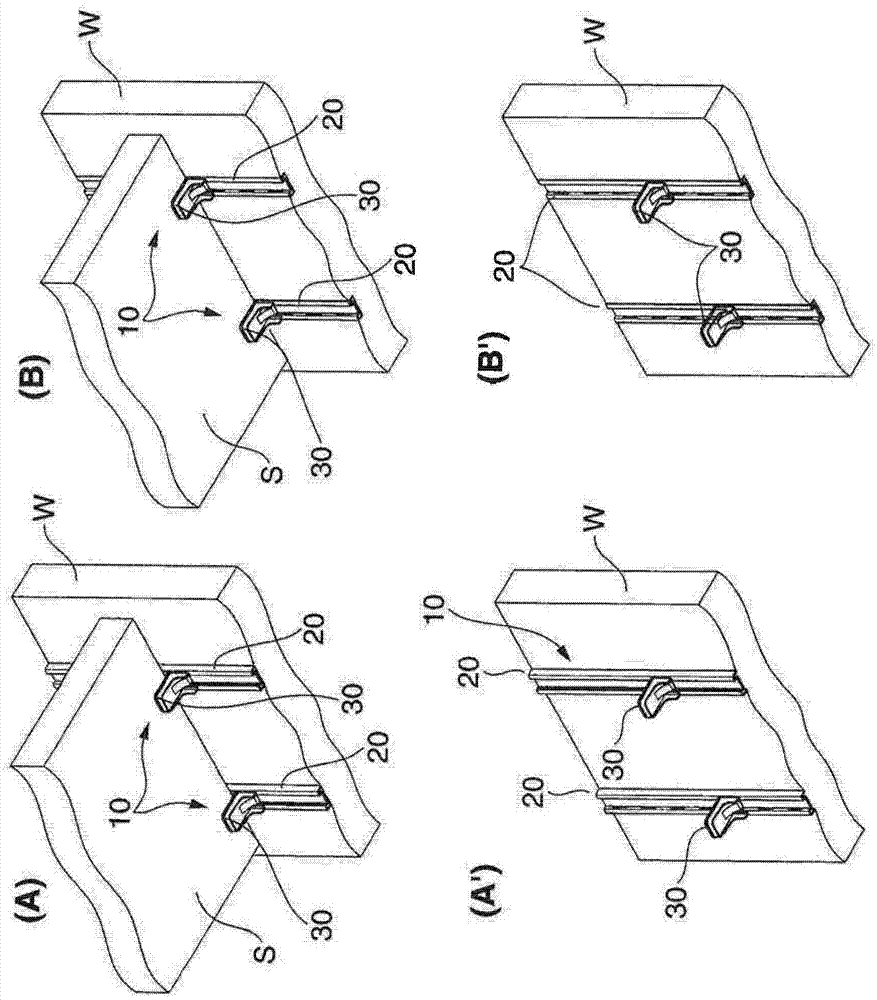

[0069] refer to Figure 1 to Figure 11 Describe the first embodiment of the present invention in detail, figure 1 The box C having a shelf using the shelf support installation device 10 of the present invention is shown in the figure, and the partitions S are mounted on the front, rear, left, and right corners of the inner wall of the box C by the shelf support installation device 10 of the present invention. On a shelf support 30, items to be supported by the shelf are placed on the shelf S. Four shelf supports 30 are mounted on corresponding shelf columns 20 . In addition, the present invention can also be applied to, for example, a shelf in which a shelf S is placed across two shelf supports 30 and articles are loaded on the shelf S. As shown in FIG.

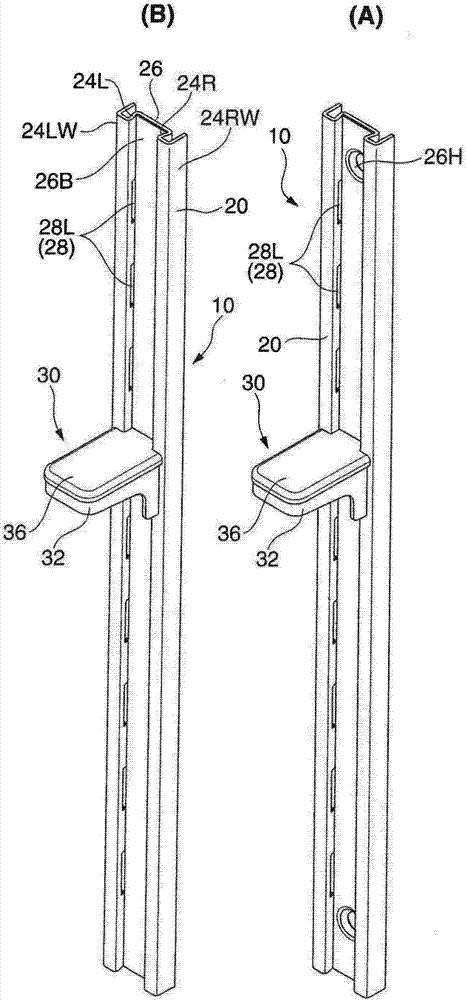

[0070] The shelf support mounting device 10 of the present invention is shown in Figure 2 below. The shelf columns 20 are installed on the installation wall W with appropriate devices, and the shelf support members 30 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com