Transformation static curing equipment for foods and curing method thereof

A static and equipment technology, applied in the field of food processing, can solve the problems of accelerating the dissolution of muscle protein and destroying the shape of the product, and achieve the effect of improving the pickling efficiency, reducing the mutual extrusion and maintaining the integrity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings, so that those of ordinary skill in the art can implement it after referring to this specification.

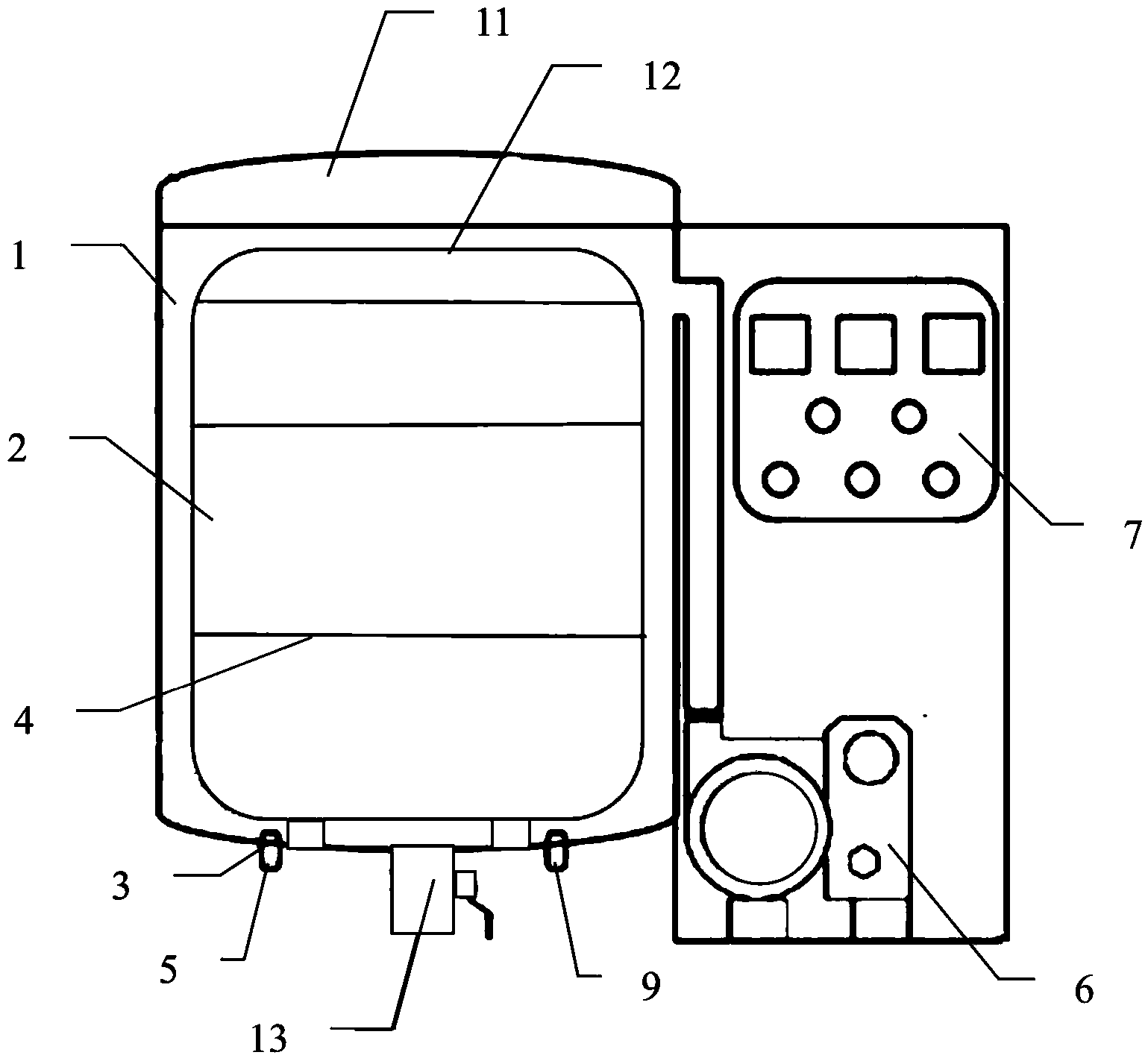

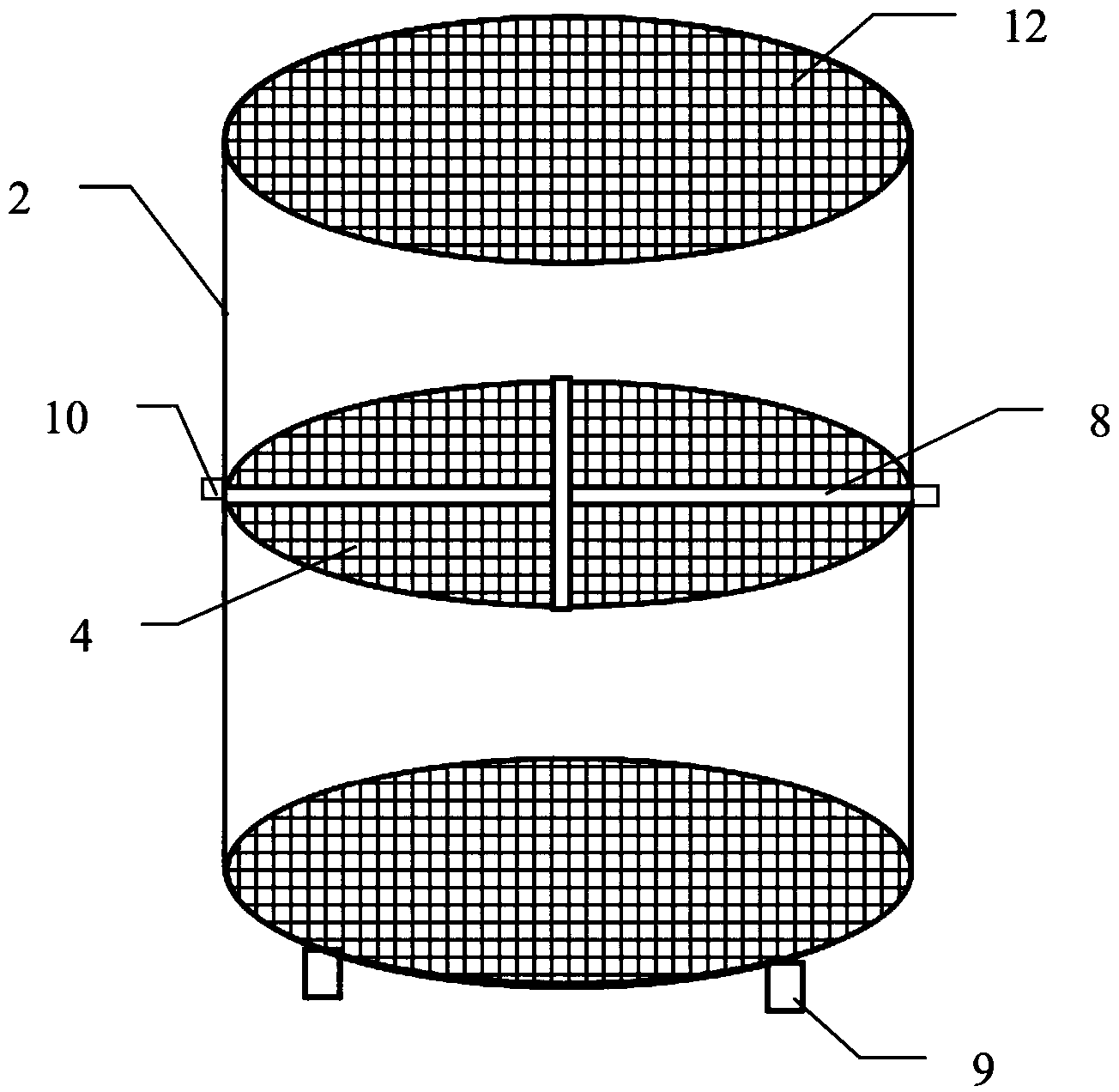

[0027] Such as figure 1 As shown, a variable pressure static pickling equipment for food, which includes:

[0028] A pickling tank includes a pickling tank body 1 and an inner cylinder 2. The bottom of the pickling tank body 1 is provided with at least one air inlet 3; the cylinder wall and bottom of the inner cylinder 2 are both set in a grid shape , The inner cylinder 2 is sleeved inside the pickling tank body 1 to form a double-layered cylindrical structure with an internal space communicating with each other, the pickling liquid is directly added into the pickling tank body 1, and the materials to be pickled are placed inside In the cylinder 2, the pickling liquid penetrates the mesh of the inner cylinder 2 to contact the material to be pickled. The use of a double-laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com