Plateau corn flour and preparation method thereof

A grain and flour technology, applied in the field of food processing, can solve the problems of unattractive color, poor taste, rough taste, etc., and achieve the effect of promoting metabolism, unique flavor and controlling blood sugar

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

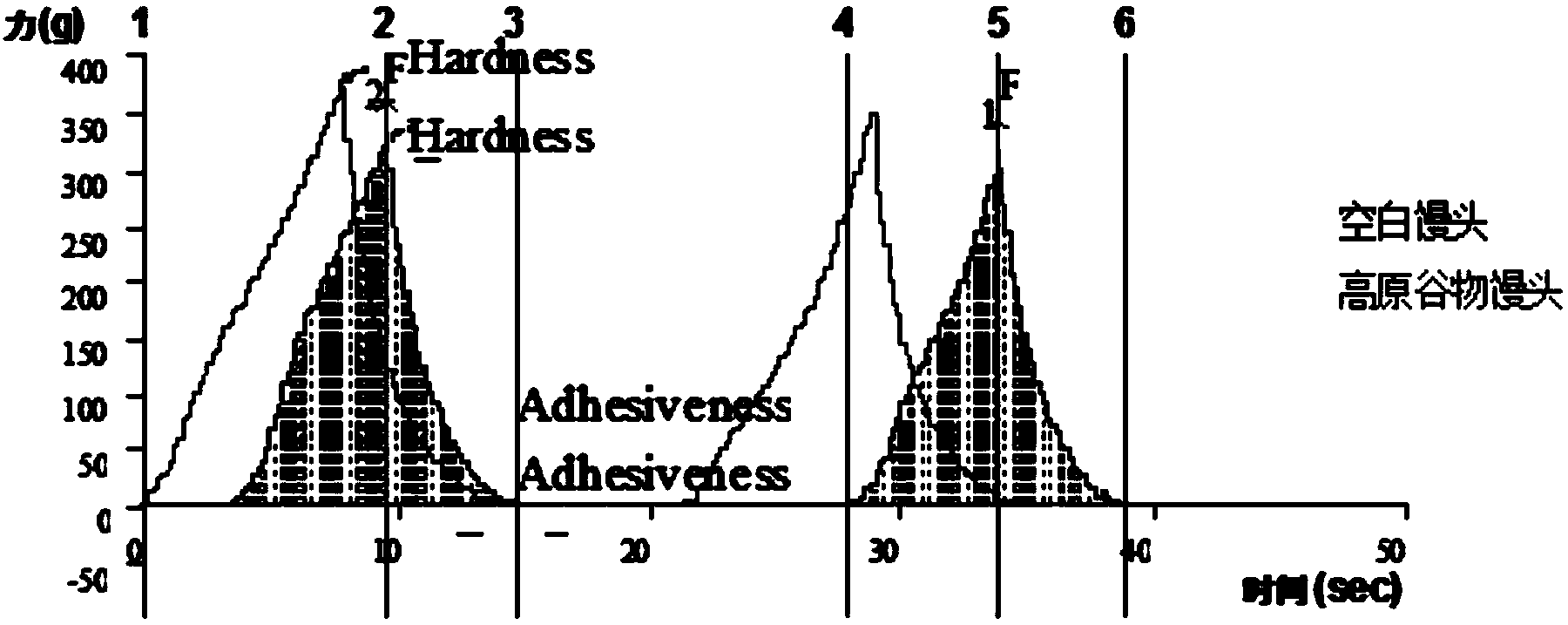

Image

Examples

Embodiment 1

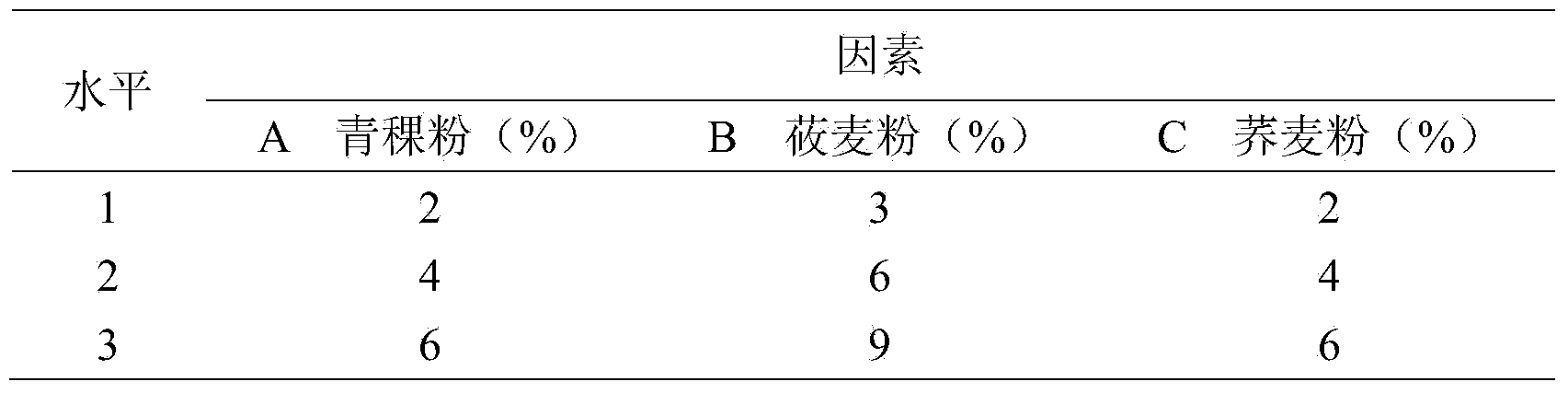

[0022] The plateau grain flour in this embodiment is composed of the following components in mass percentage: 2% highland barley flour, 3% naked oat flour, 2% buckwheat flour, and the balance is wheat flour.

[0023] The preparation method of plateau cereal flour in the present embodiment, comprises the following steps:

[0024] (1) Fry highland barley (produced in Tibet), naked oats (Inner Mongolia), and buckwheat (Inner Mongolia) at 120°C respectively, then bake at 150°C, and crush them into fine powder;

[0025] (2) Take highland barley flour, naked oat flour, buckwheat flour and wheat flour according to the mass percentage, first mix the highland barley flour, naked oat flour and buckwheat flour, then add them into the wheat flour, and continue to mix well.

Embodiment 2

[0027] The plateau grain flour in this embodiment is composed of the following components in mass percentage: 4% barley flour, 15% naked oat flour, 8% buckwheat flour, and the balance is wheat flour.

[0028] The preparation method of plateau cereal flour in the present embodiment, comprises the following steps:

[0029] (1) Fry highland barley (produced in Tibet), naked oats (Inner Mongolia) and buckwheat (Inner Mongolia) at 100°C respectively, then bake at 140°C, and crush them into fine powder;

[0030] (2) Take highland barley flour, naked oat flour, buckwheat flour and wheat flour according to the mass percentage, first mix the highland barley flour, naked oat flour and buckwheat flour, then add them into the wheat flour, and continue to mix well.

Embodiment 3

[0032] The plateau grain flour in this embodiment is composed of the following components in mass percentage: 6% barley flour, 6% buckwheat flour, 10% buckwheat flour, and the balance is wheat flour.

[0033] The preparation method of plateau cereal flour in the present embodiment, comprises the following steps:

[0034] (1) Fry highland barley (produced in Tibet), buckwheat (Inner Mongolia) and buckwheat (Inner Mongolia) respectively at 130°C, then bake at 150°C, and pulverize into fine powder;

[0035] (2) Take highland barley flour, naked oat flour, buckwheat flour and wheat flour according to the mass percentage, first mix the highland barley flour, naked oat flour and buckwheat flour, then add them into the wheat flour, and continue to mix well.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com