Sheep skin tearing machine

A technology of rolling skins and racks, which is applied to skinning tools, slaughtering accessories, slaughtering and other directions, can solve the problems of high skin and meat rate, uneven force, complicated control, etc., and achieves low skin and meat rate, convenient adjustment, The effect of low manufacturing and processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

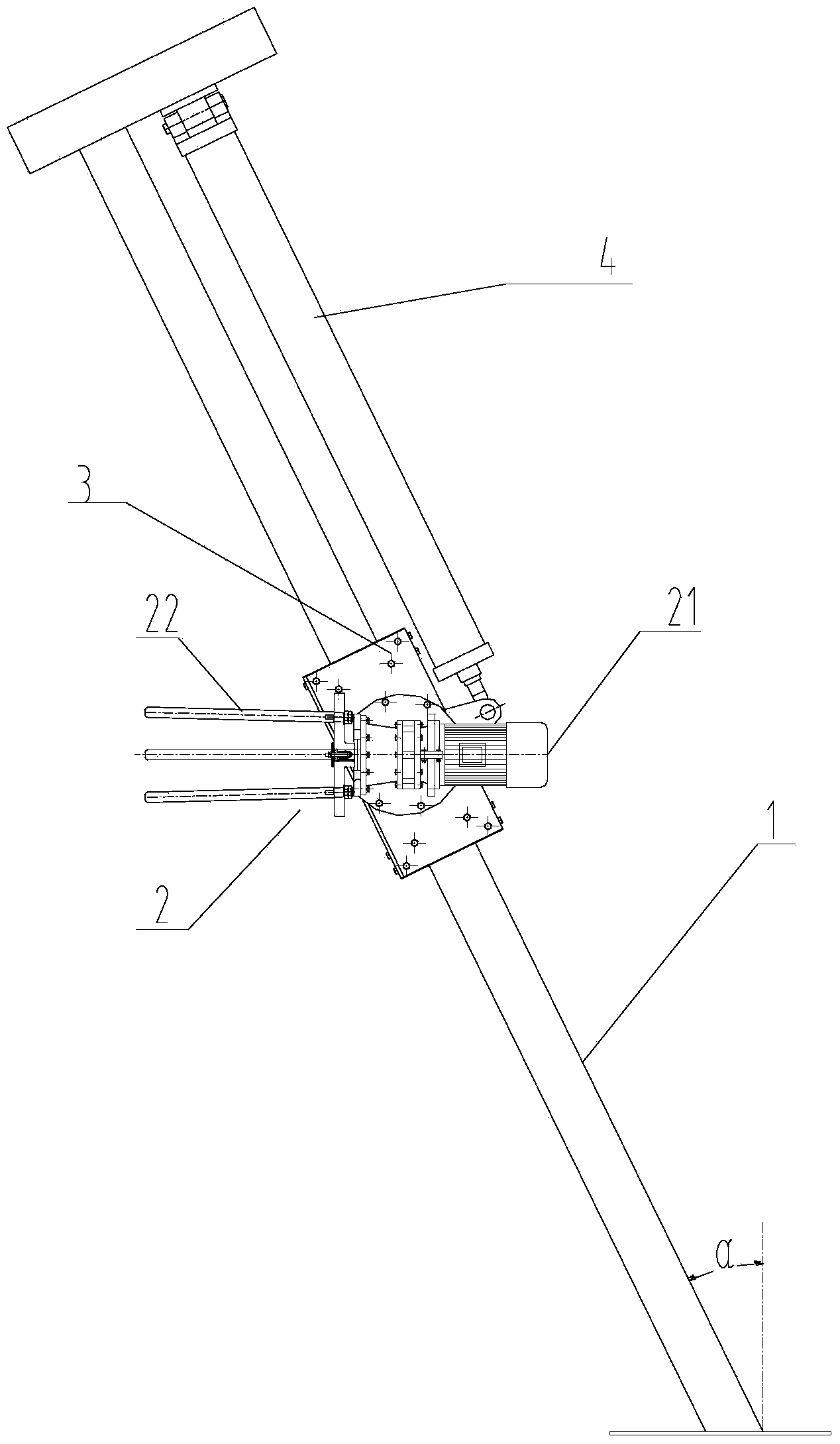

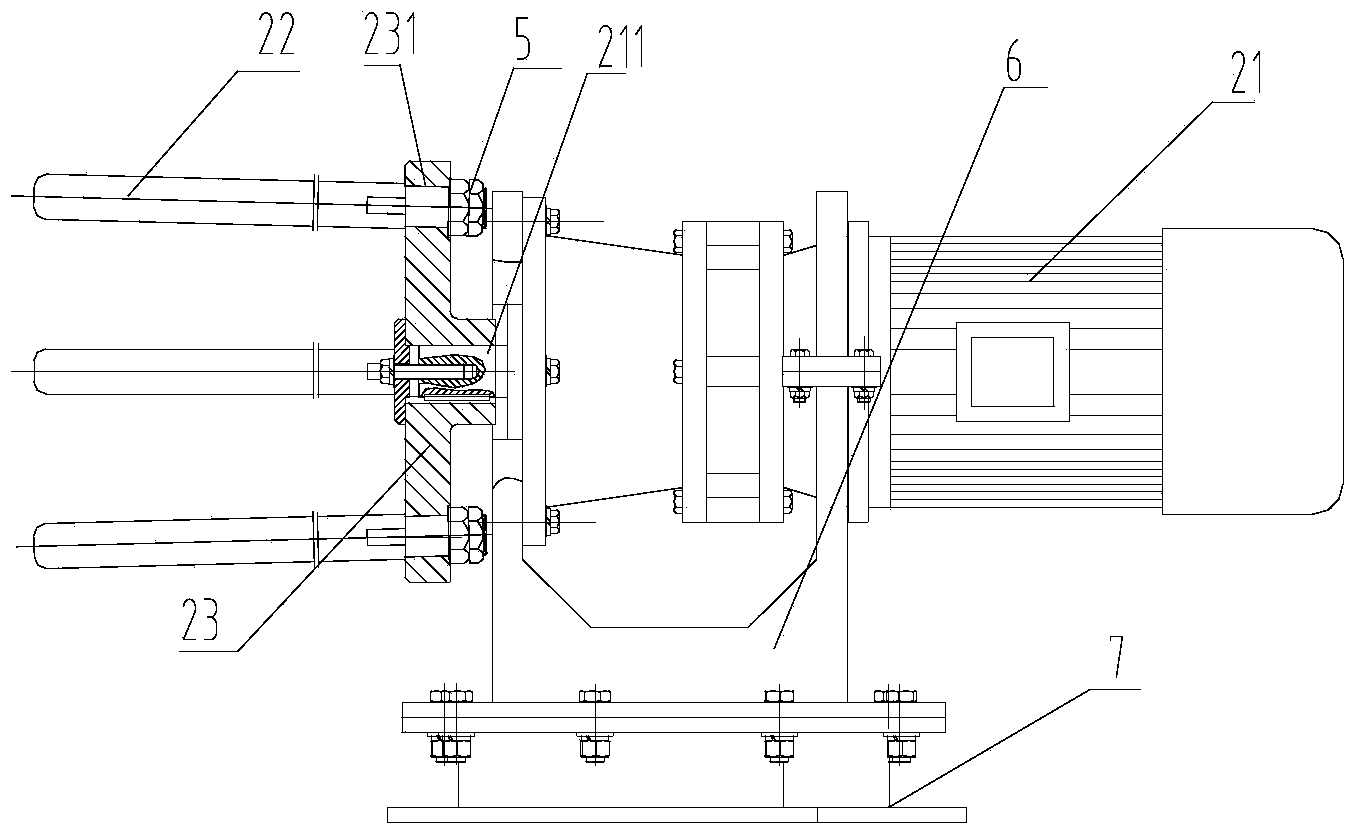

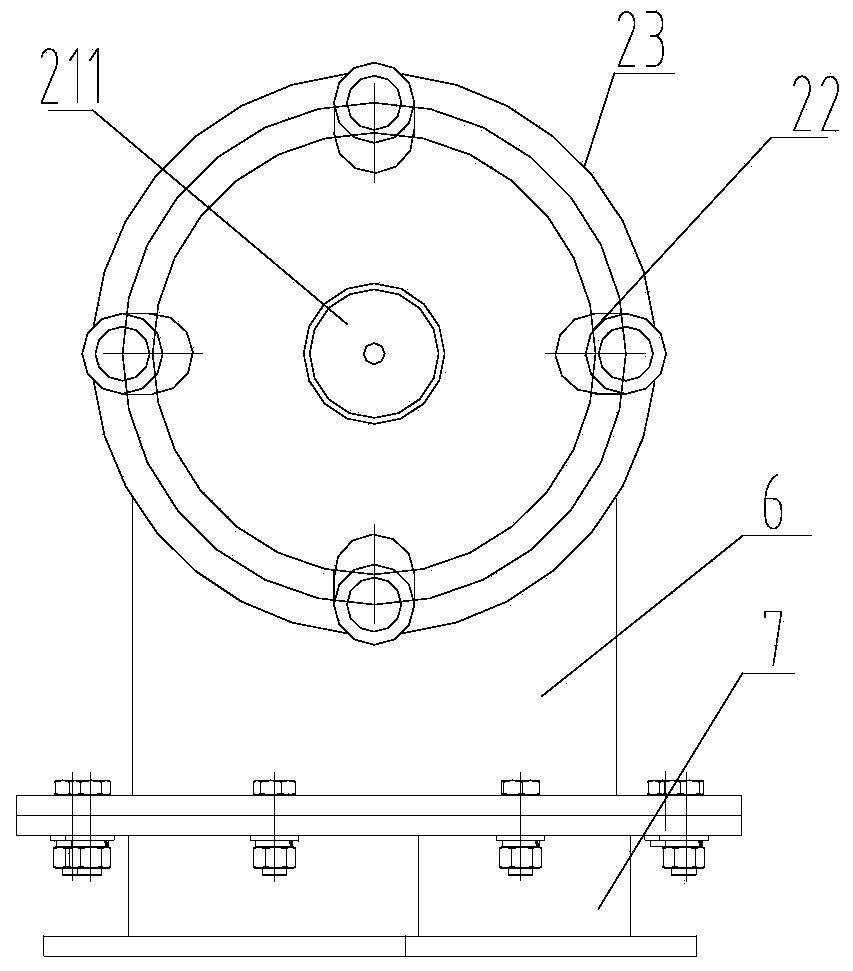

[0035] Such as figure 1 Shown, the invention provides a kind of sheep skinning machine, comprises inclined frame, rolling device, drive unit, moving unit. The rolling device realizes the action of winding the sheepskin on the rolling shaft, and the driving device drives the mobile device to reciprocate along the inclined support. The inclined support here is an inclined guide rail, through the compound movement of the rotation of the rolling device and the descent of the moving device Thereby realize that the sheepskin is torn off from the sheep carcass. The rolling device rotates in the opposite direction to remove the sheepskin, and the sheepskin is transported away by other means. At the same time, the moving device rises to return...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com