Universal follow-up bias adjusting polished rod sealing mechanism

A sealing mechanism and follow-up technology, applied in sealing/isolation, wellbore/well components, earthwork drilling and production, etc., can solve problems such as loss of sealing effect, wellhead oil drainage, and unsealed polished rods, etc., to extend the adjustment period , to solve the effect of oil leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

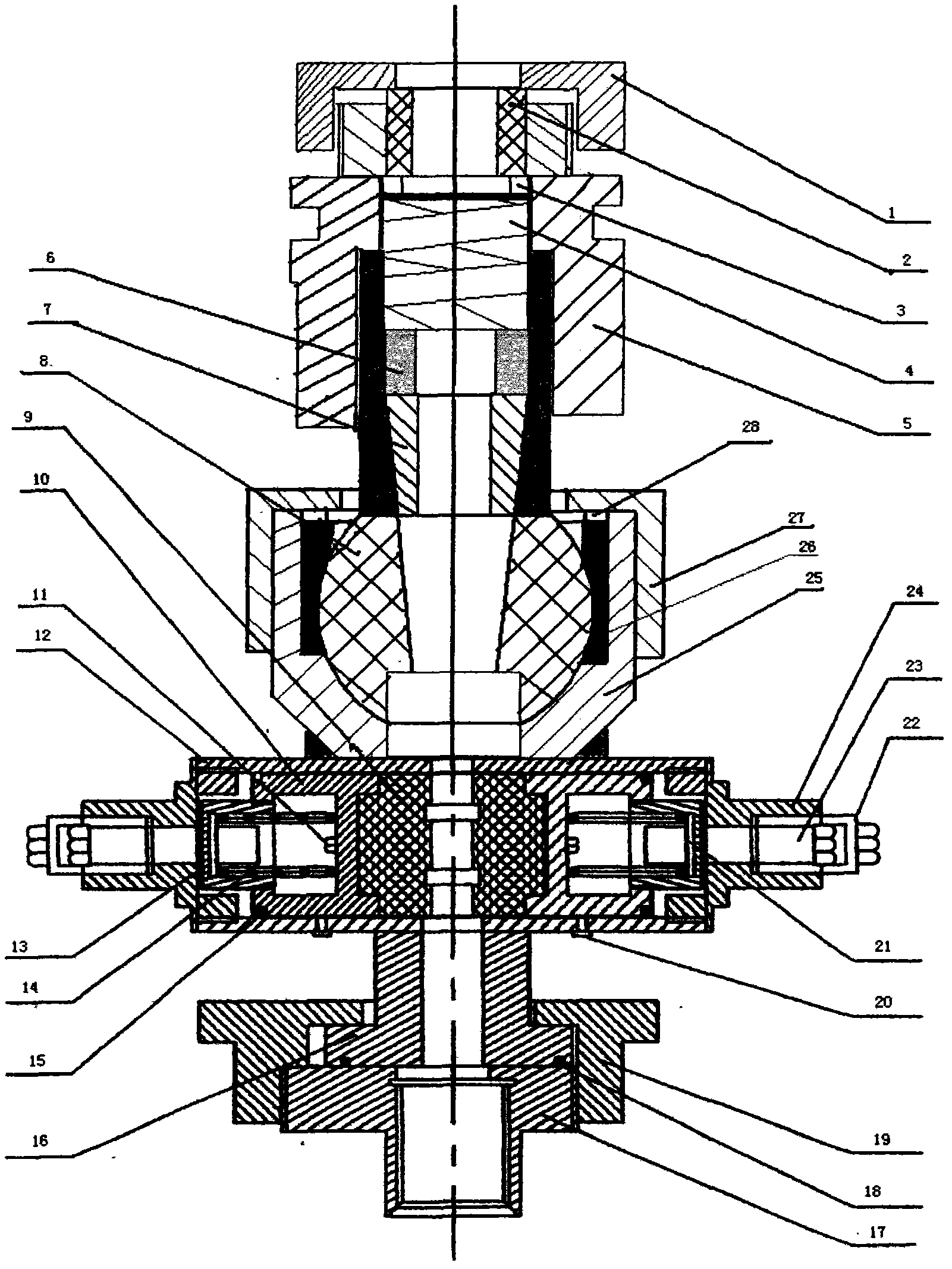

[0014] As shown in the attached figure, the sealing mechanism of the spherical follow-up universal polarizing rod is composed of two parts: the working sealing valve and the standby sealing valve. The seat lock nut is fixed on the 25 ball valve seat, the upper valve is a sealing valve when the pumping unit is working, and the lower valve is a backup valve for sealing without stopping the pumping unit when replacing the seal of the upper valve. The working sealing valve consists of upper gland 1, righting block 2, spring gland 3, spring 4, adjustment sleeve 5, waist drum packing 6, cone packing 7, ball deflection adjustment studio 8, ball sealing block 26, ball valve chamber Gasket 28 constitutes. Waist drum packing 6 and cone packing 7 are installed in the chamber hole of the sphere deflection adjustment studio 8, the spring 4 is placed on the waist drum packing 6 by the spring cover 3, and a regulating valve is installed outside the sphere deflection adjustment studio 8 throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com