Combined fixture for machining of breaker shell

A circuit breaker and combined technology, which is applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of low product processing position accuracy, lower product production efficiency, cumbersome positioning adjustment, etc., to shorten the development cycle, Improve production efficiency and good clamping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

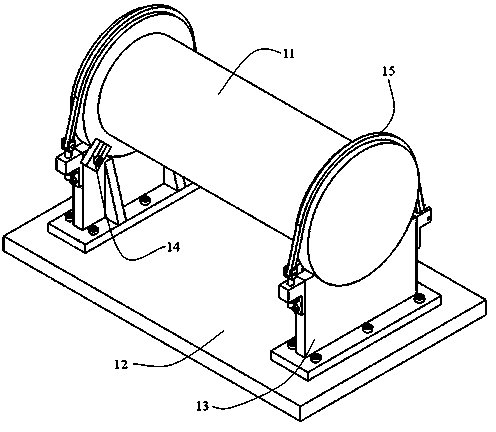

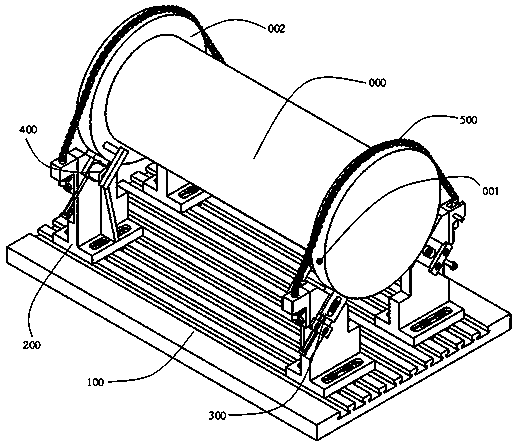

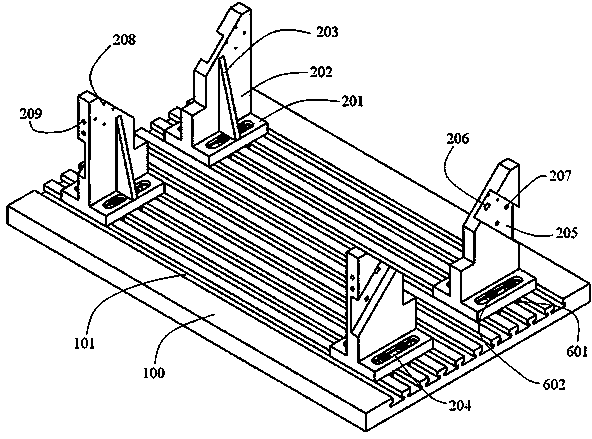

[0054] like figure 2 As shown, the fixture of the present invention includes a clamp body composed of a bottom plate 100 and 4 supports 200, a positioning element composed of 4 sets of slider positioning devices 300 and 4 sets of corner cylinder positioning devices 400, and a set of 2 sets of chain locking devices 500. The locking device and several connecting elements 600 are formed. Before installing the workpiece 000, according to the total length and diameter of the workpiece 000, adjust the installation positions of the four supports 200 on the base plate 100, and make them symmetrical with respect to the longitudinal and transverse centerlines of the base plate 100. After the positions are adjusted, place the Four supports 200 are fixed on the bottom plate 100 . The workpiece is placed, the flanges at both ends of the workpiece 000 are respecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com