A high-pressure flat belt dehydration device

A dewatering device and flat belt technology, applied in filtration and separation, separation methods, moving filter element filters, etc., can solve the problems of difficulty in meeting the requirements of sludge dewatering, low filter dryness, and many operators, and save energy. The effect of conveying equipment and conveying energy consumption, continuous filter press process, and low operating energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

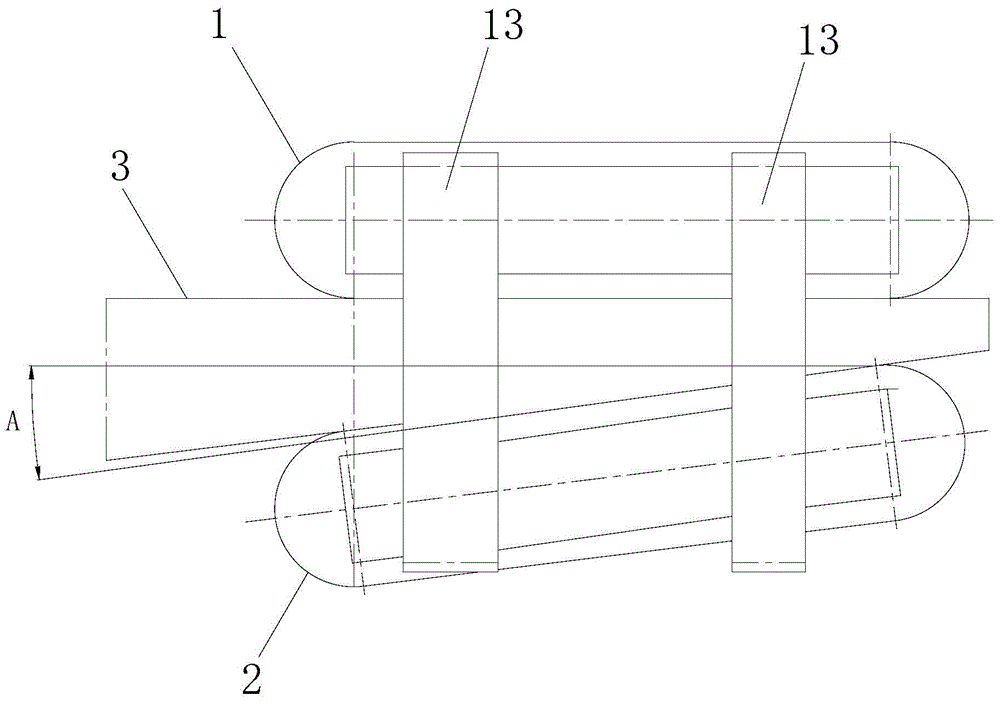

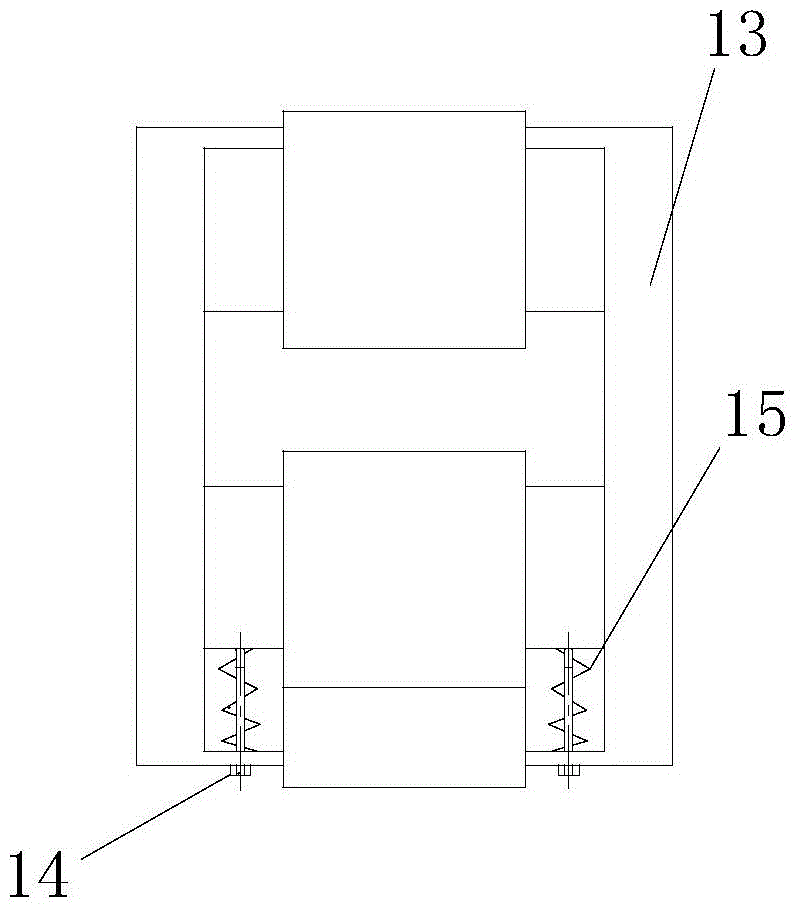

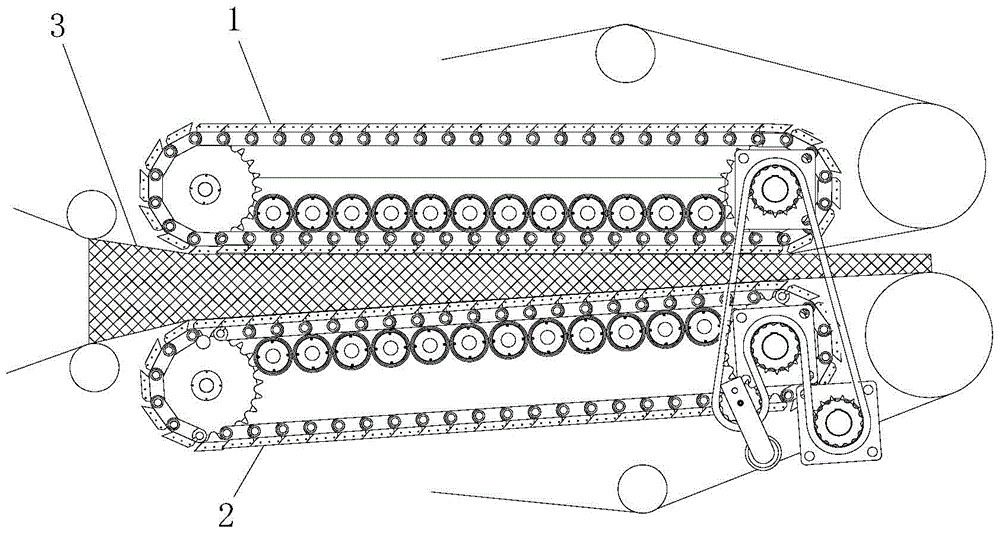

[0032] A high-pressure flat belt dehydration device, including an upper mud pressing belt 1, a lower mud pressing belt 2, a power system for driving the upper mud pressing belt and a lower mud pressing belt to circulate, and a filter cloth system for wrapping sludge 3. The upper mud-pressing zone 1 and the lower mud-pressing zone 2 are arranged obliquely to form a filter press zone where the distance between the upper mud-pressing zone 1 and the lower mud-pressing zone 2 gradually decreases. In order to further improve the filter press efficiency, preferably, use the existing belt filter press 4 to pre-press before using the present invention, and the filter cloth system 3 enters the filter press area of the present invention after being output by the belt filter press 4 Press filter.

[0033] The upper mud-pressing belt 1 and / or the lower mud-pressing belt 2 are mainly formed by several chain links 5 which are hinged together. The chain links 5 have a male hinged end 6 and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com