Craft outer skin heat exchanger and method for manufacturing craft outer skin heat exchanger

A heat exchanger, aircraft technology, used in aircraft parts, heat exchange equipment, transportation and packaging, etc., can solve problems such as high cooling demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

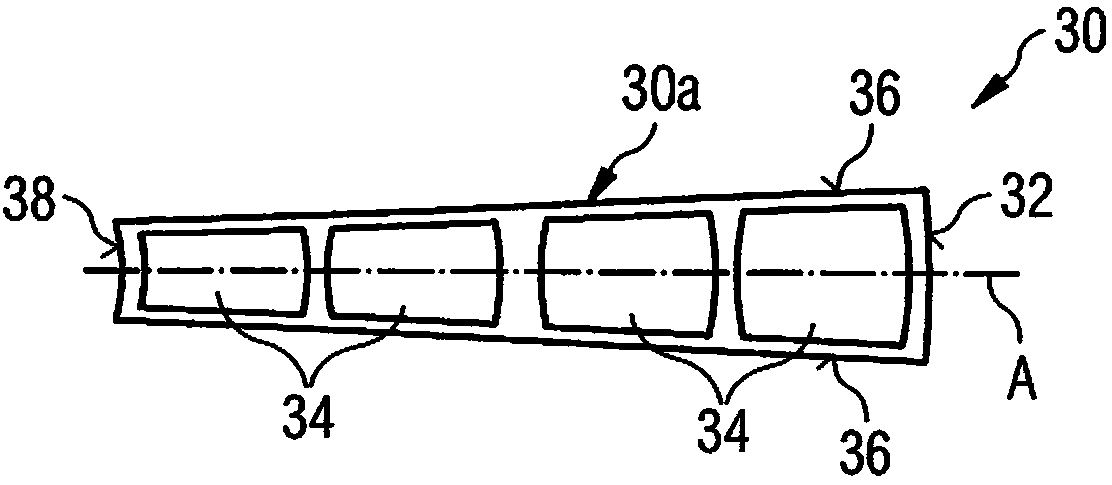

[0037] Figure 1A to Figure 1D Four different embodiments of heat transfer modules 10, 20, 30, 40 are shown, each of which can be formed such as Figure 2 to Figure 5 One of the layers of the multilayer body 102, 202, 302 of the heat exchanger 100, 200, 300 is shown. Each heat exchanger multilayer body 102, 202, 302 includes such as Figure 1A to Figure 1D A plurality of heat transfer modules 10, 20, 30, 40 are shown in . If desired, only one type of heat transfer module 10 , 20 , 30 , 40 may be employed in the heat exchanger multilayer body 102 , 202 , 302 . Alternatively, however, it is also conceivable to equip the heat exchanger multilayer body 102, 202, 302 with e.g. Figure 1A , Figure 1B , Figure 1C or Figure 1D At least two different types of heat transfer modules 10, 20, 30, 40 are shown in .

[0038] Figure 1A The heat transfer module 10 shown in includes a heat transfer module body 10a and ribs or fins 12 integrally formed with the heat transfer module bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com