Washing machine motor with mute function

A washing machine and functional technology, applied in the direction of electromechanical devices, electrical components, magnetic circuit shape/style/structure, etc., can solve problems such as affecting motor operation, large deformation of rubber shock absorption layer, large concentricity, etc., to ensure normal operation, Improve mute effect and good shock absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but it is not used as a basis for limiting the present invention.

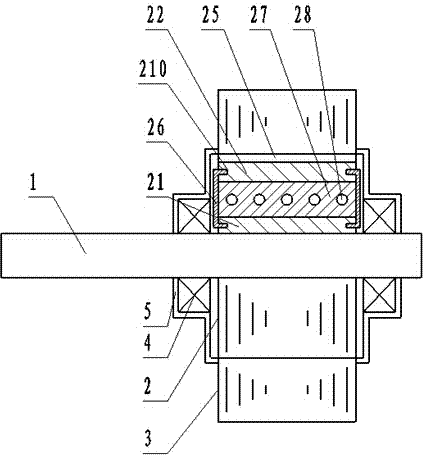

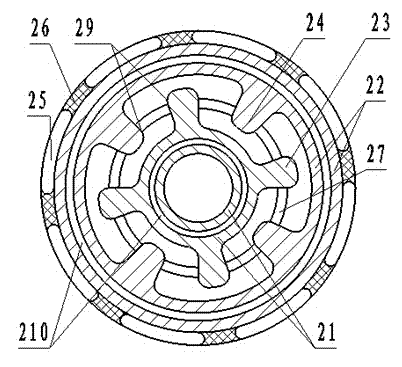

[0013] Example. Washing machine motor with mute function, constituted as figure 1 , 2 Said, including rotating shaft 1, rotor 2, stator 3, bearing 4 and end cover 5; Said rotor 2 comprises inner rotor 21, and outer rotor 22 is arranged on the outer side of inner rotor 21; The outward convex portion 23, the inner surface of the outer rotor 22 is provided with a number of radially inward inner convex portions 24, and there is a certain space between the adjacent outer convex portions 23 and the inner convex portions 24; the outer rotor 22 Evenly distributed permanent magnets 25 are connected on the outer surface, and a PBT connection seat 26 is arranged between two adjacent permanent magnets 25; a ring-shaped rubber shock-absorbing layer 27 is arranged between the inner rotor 21 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com