Open-loop fuzzy control method for piezoelectric ceramic driver hysteresis system

A piezoelectric ceramic and fuzzy control technology, which is applied in the control field of ultra-precision optical applications, can solve the problems of poor adaptability of open-loop controllers and open-loop ambiguity of hysteresis systems, and achieves convenient real-time application, high modeling accuracy, and realization of simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

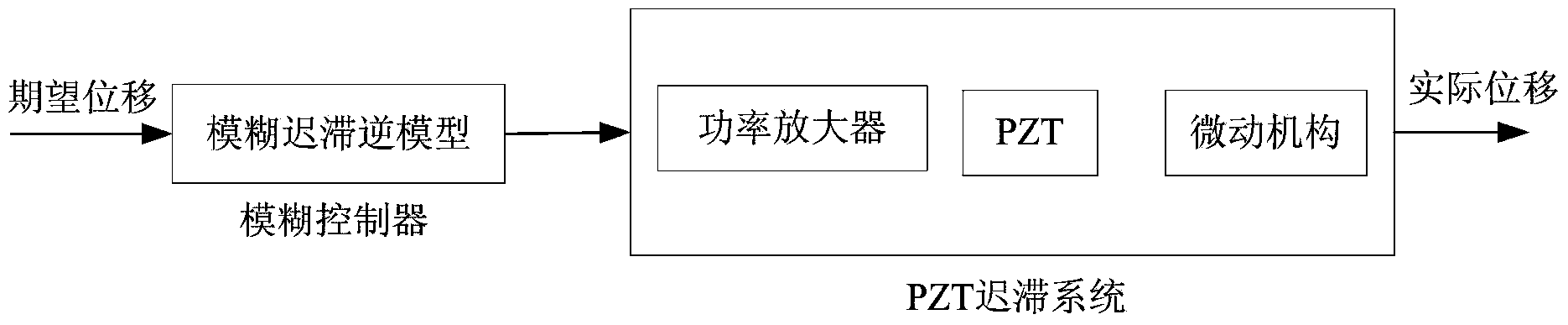

[0023] Specific implementation mode 1. Combination figure 1 and figure 2 Describe this embodiment, the open-loop fuzzy control method of piezoelectric ceramic actuator hysteresis system, such as figure 1 , this embodiment is carried out for the PZT hysteresis system, the hysteresis system is mainly composed of a power amplifier, PZT and a micro-motion mechanism. The power amplifier amplifies the voltage of the output of the fuzzy controller to drive the PZT movement with the help of the inverse piezoelectric effect. The micro-motion mechanism is a one-dimensional precision positioning translation platform based on flexible hinge transmission, which guides the PZT movement with a single degree of freedom and bears a certain weight. load. According to the fuzzy hysteresis inverse model obtained, the fuzzy controller is implemented by a digital signal processor (Digital Signal Processor, DSP).

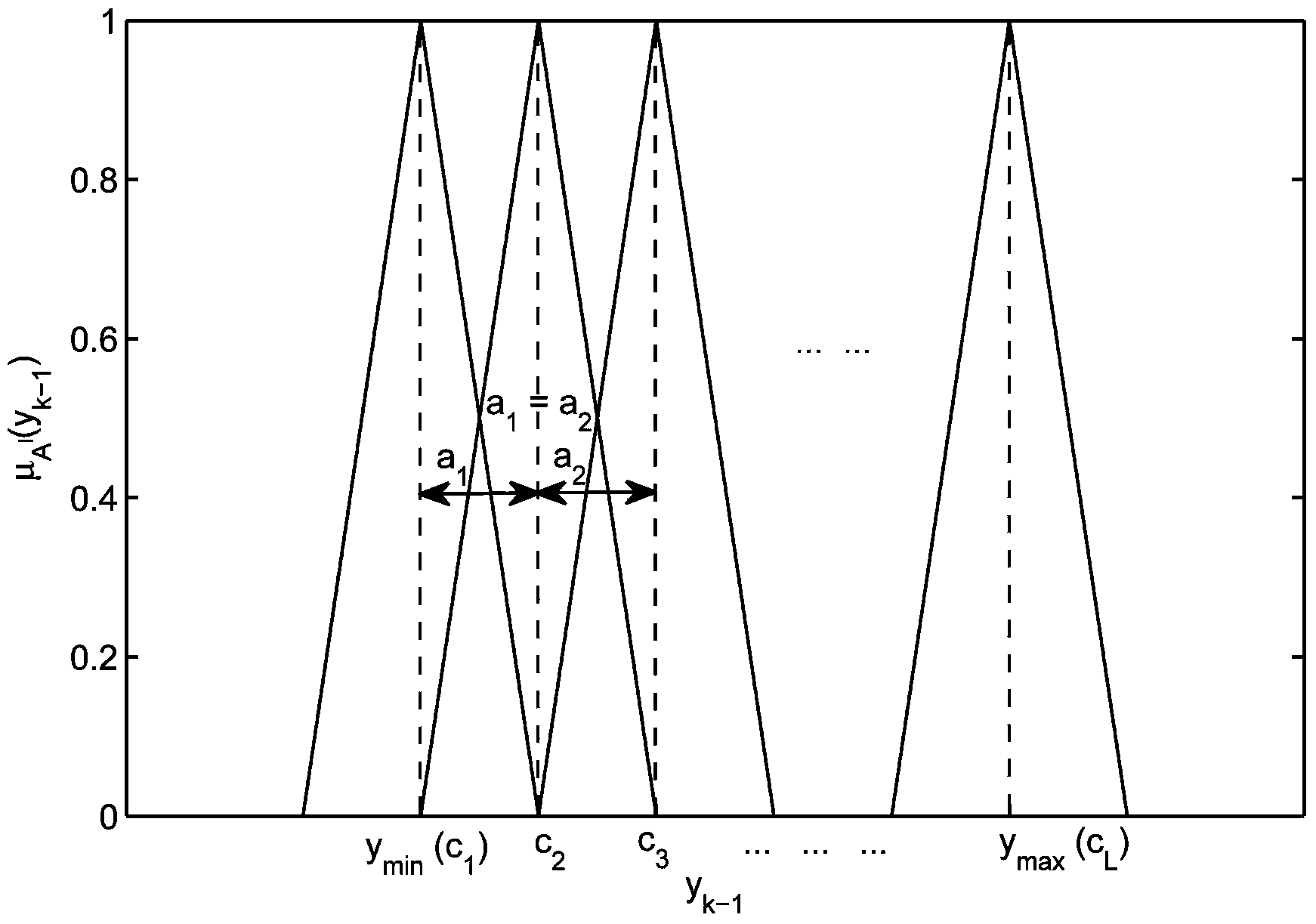

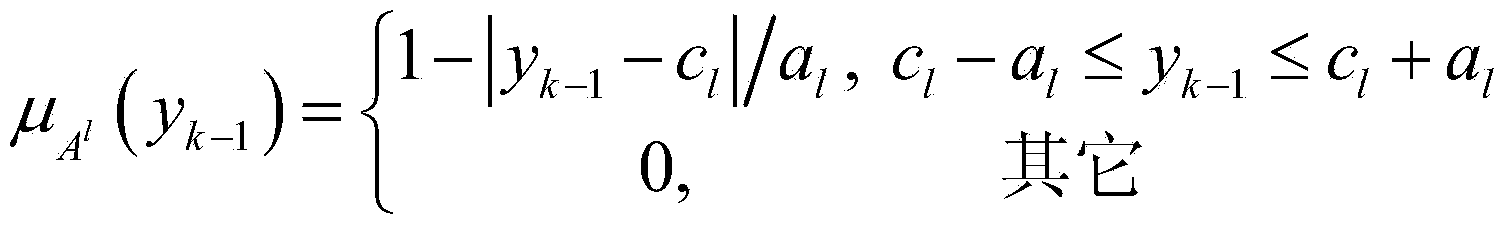

[0024] combine figure 2 , the fuzzy hysteresis model input variable y in this e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com