Online testing device for performance of laser gyroscope reflector

A technology of online testing and laser gyroscope, which is applied in the direction of testing optical performance, can solve problems such as the impact of laser performance, and achieve the effect of improving overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing and specific implementation the present invention will be further described:

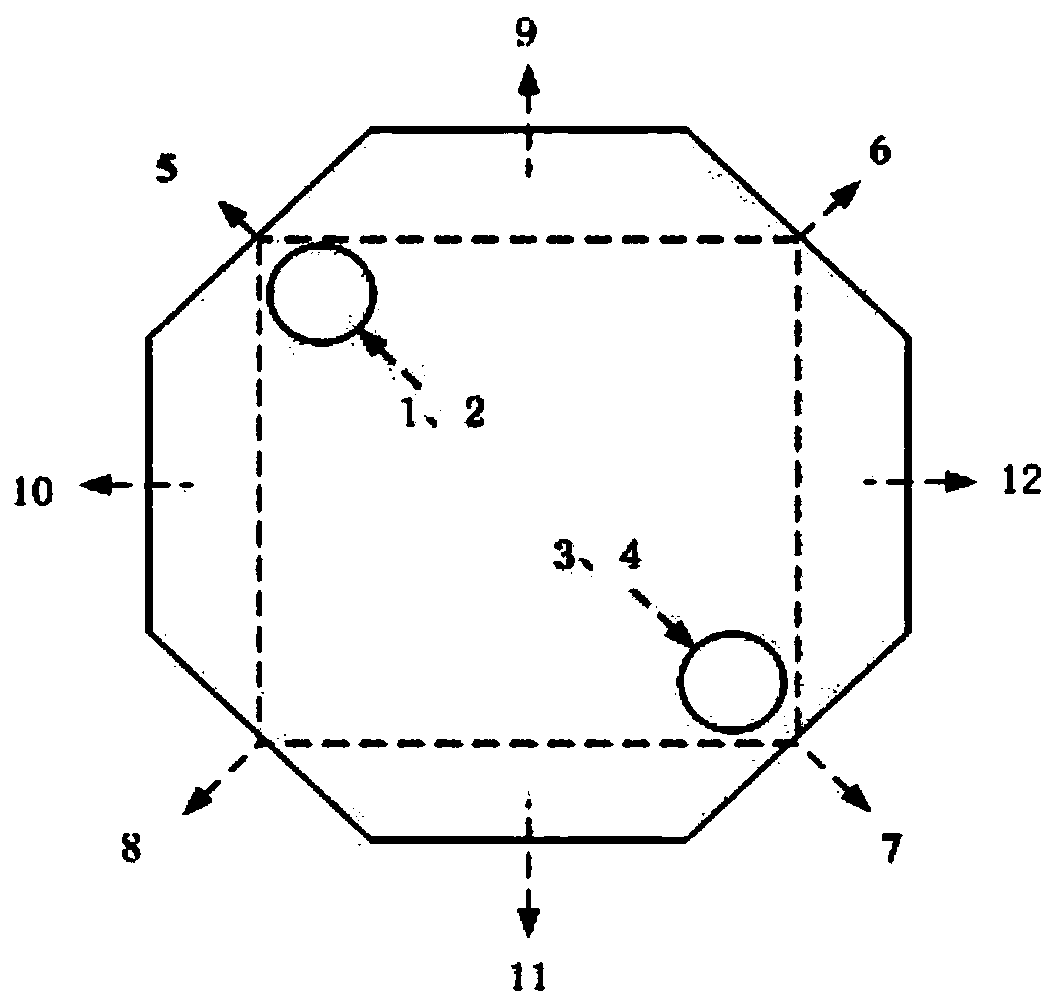

[0024] Such as figure 1 As shown, an online test device for the performance of laser gyro mirrors is obtained by mechanical processing, optical processing and chemical polishing of a cube-shaped glass-ceramic material. The main body is a right prism cavity with a decahedral structure. It is an octagon with each internal angle of 135°, and the octagon is formed by connecting line segments with lengths L1 and L2 at intervals; L1=31mm, L2=46mm, and the height of the right prism is 40-60mm; There is a central through hole with a diameter of 50 mm; a spherical output mirror, an anode 1, a cavity translation mirror, a cathode, a planar output mirror, an anode 2, a spherical total reflection mirror and a blank surface are arranged sequentially on the six sides of the straight prism. In this embodiment, the positions where the spherical output mirror, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Transmittance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com