Efficient condensation vacuum oil purifier

A vacuum oil purifier, high-efficiency technology, applied in steam/steam condensers, lighting and heating equipment, etc., can solve the problem of poor working efficiency of vacuum oil purifiers, poor thermal insulation performance and automatic performance, and the use effect of condenser tubes Poor and other problems, to achieve the effect of improving the condensation effect, improving the production efficiency of enterprises, and improving the effect of heat preservation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing.

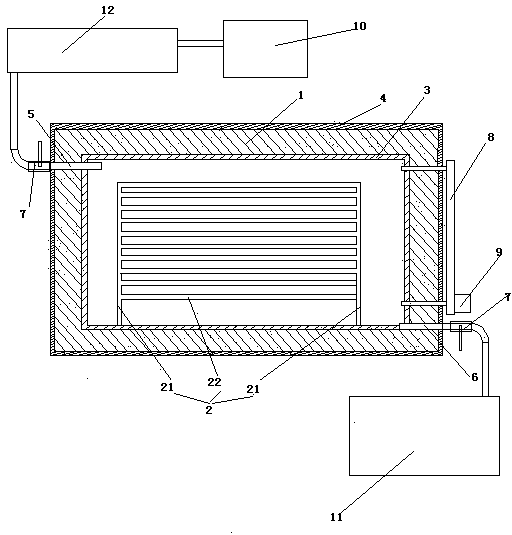

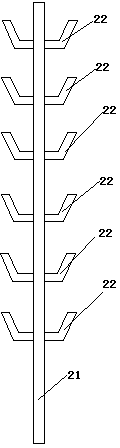

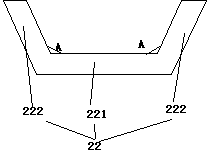

[0018] As shown in the figure, a high-efficiency condensing vacuum oil purifier of the present invention includes a cold water tank 1, a control box 10, a waste water tank 11, and a separator 12, wherein the cold water tank 1 is provided with a condensation rack 2, The condensing frame 2 includes two supporting frames 21 and a plurality of condensing blades 22, the supporting frame 21 is vertically fixed on the inner bottom surface of the cold water tank 1, and is distributed left and right; the condensing blades 22 are longitudinally distributed between the supporting frames 21 Between, the two ends of the condensing blade 22 are connected to two support frames 21; the condensing blade 22 is an integrated structure, including a bottom plate 221 and a side plate 222, and the number of the side plates 222 is two, connected to the bottom plate 221 At both ends, the two side p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com