A method for enhanced drainage of coal bodies caused by gas explosion fracturing in boreholes

A technology of gas explosion and gas extraction, which is applied in the field of efficient gas extraction and can solve the problems of personnel poisoning and death

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

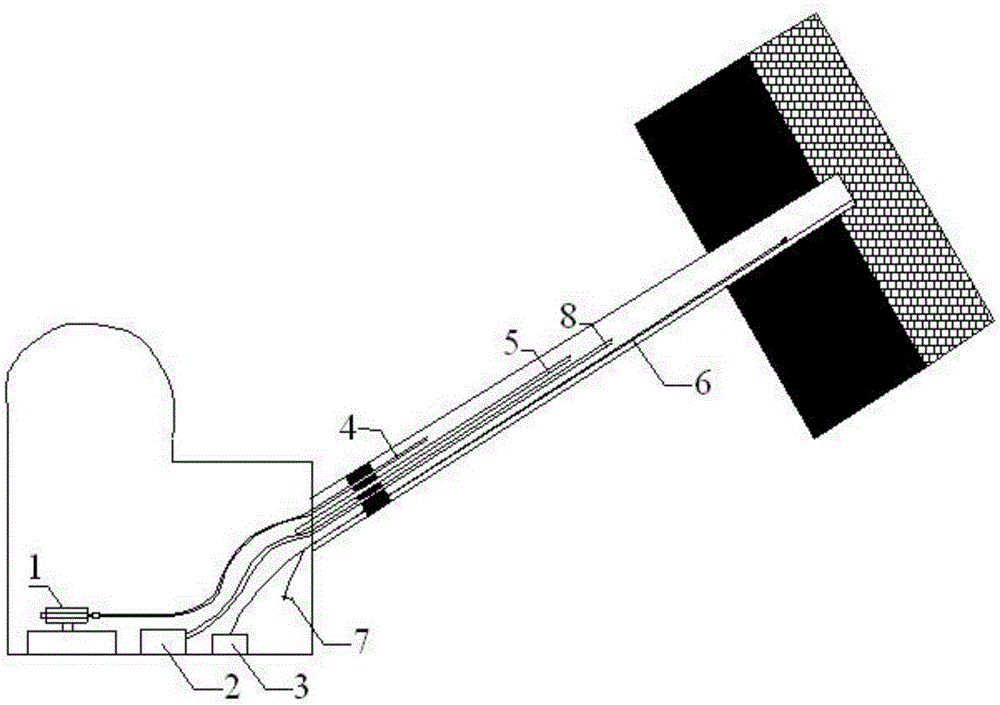

[0017] An embodiment of the present invention will be further described below in conjunction with the accompanying drawings:

[0018] Such as figure 1 As shown, the method for intensified extraction of coal by gas explosion in a borehole of the present invention, the specific steps are as follows:

[0019] a. According to the conventional method, the positions of the drainage holes and the explosion holes are staggered in the coal seam;

[0020] b. Construct drainage holes, seal holes, and connect them to the gas drainage pipe network for gas drainage;

[0021] c. Use a drilling rig to drill at the location of the explosion hole to 1m through the roof of the coal seam, and withdraw the drill;

[0022] d. Bind the wire of the ignition device 3 to the detection tube 6, and then send the detection tube 6 into the bottom of the explosion hole, so that the front end of the wire tied to the detection tube 6 is located in the middle of the coal seam; the detection tube 6 is evenly located on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com