Upper turnover plate self-locking mouse hole chuck

A technology of flaps and mice, which is applied to drilling equipment, earth-moving drilling, drill pipes, etc., can solve problems such as hidden safety hazards, wear and tear of mouse holes, and impact on service life, so as to achieve convenient use and wide application range. , Reliable locking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing, the specific embodiment of the present invention is described in further detail:

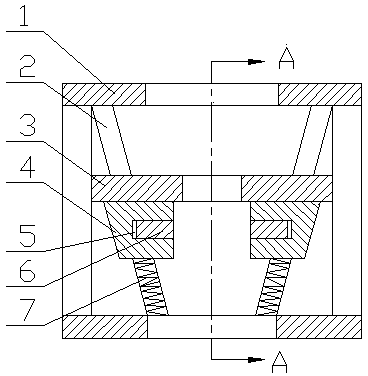

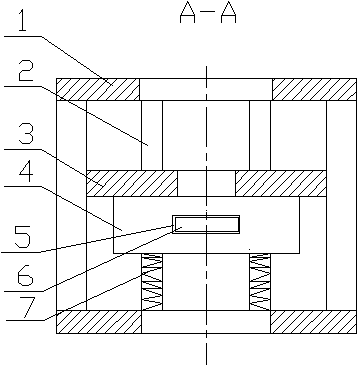

[0017] As shown in the figure, a self-locking mouse hole chuck with an upper flap includes a casing 1 and a guide mechanism and a locking mechanism arranged in the casing 1. The guide mechanism includes four guide columns 2 and an upper flap 3, The guide column 2 is symmetrically arranged in the casing in a trapezoidal shape, the upper end of the guide column 2 is connected to the upper top plate of the casing 1, the lower end of the guide column 2 is connected to the lower base of the casing 1, and the upper flap 3 is connected through the four corners of the chute. Connected to the four guide columns 2, it is in a state of translation up and down, and the center of the upper flap 3 is provided with a drilling hole; the locking mechanism includes two symmetrically arranged sliders 4 on the left and right and an eccentric arc groove arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com